Abstract:

As a special equipment for machining spiral bevel gears, the spiral bevel gear milling machine is prone to jamming issues due to the existence of backlash during the CNC machining process, leading to impact and shock phenomena, which reduce gear machining accuracy. This paper compares anti-backlash technologies and constructs a double-motor anti-backlash method for the transmission system of a spiral bevel gear milling machine based on PMAC. The anti-backlash method is tested using a dual-motor drive application system with an IPC+PMAC motion controller. The results show that this method can effectively eliminate backlash and improve the stability of the entire CNC system. The use of the dual-motor servo anti-backlash method has certain reliability.

1. Introduction

In the transmission mechanism of a fully CNC spiral bevel gear milling machine, to avoid jamming issues when the gear pair meshes, it is customary to reserve a certain gap between the gear teeth, but precise control over the size of this gap cannot be achieved. As the transmission system undergoes long-term meshing and wear, the backlash gradually increases, causing the linear relationship between the input of the driving gear and the output of the driven gear to become nonlinear [1], resulting in reduced positional control accuracy and intensified impact collisions between gear teeth, which in turn causes the entire transmission system to oscillate [2]. The machining accuracy of the milling machine and the stability of the servo system are significantly reduced.

To ensure the stability and high-precision transmission of the gear transmission system of the milling machine turntable, anti-backlash technology emerges. Anti-backlash technologies mainly include spring anti-backlash methods, mechanical anti-backlash methods, and electrical anti-backlash methods. Among them, the spring anti-backlash method is a traditional anti-backlash technology with a relatively simple structure, but it has strict requirements on the processing accuracy of the gear rack and spring compression, and is not suitable for precision CNC machines. Although the mechanical anti-backlash method uses a special elastic coupling to add a constant torque in advance on the coupling, causing the meshing gears to generate torques in opposite directions, thereby eliminating the backlash generated during transmission, its structure is relatively complex, requiring specially made couplings and preload tools, and the stability of transmission accuracy is low.

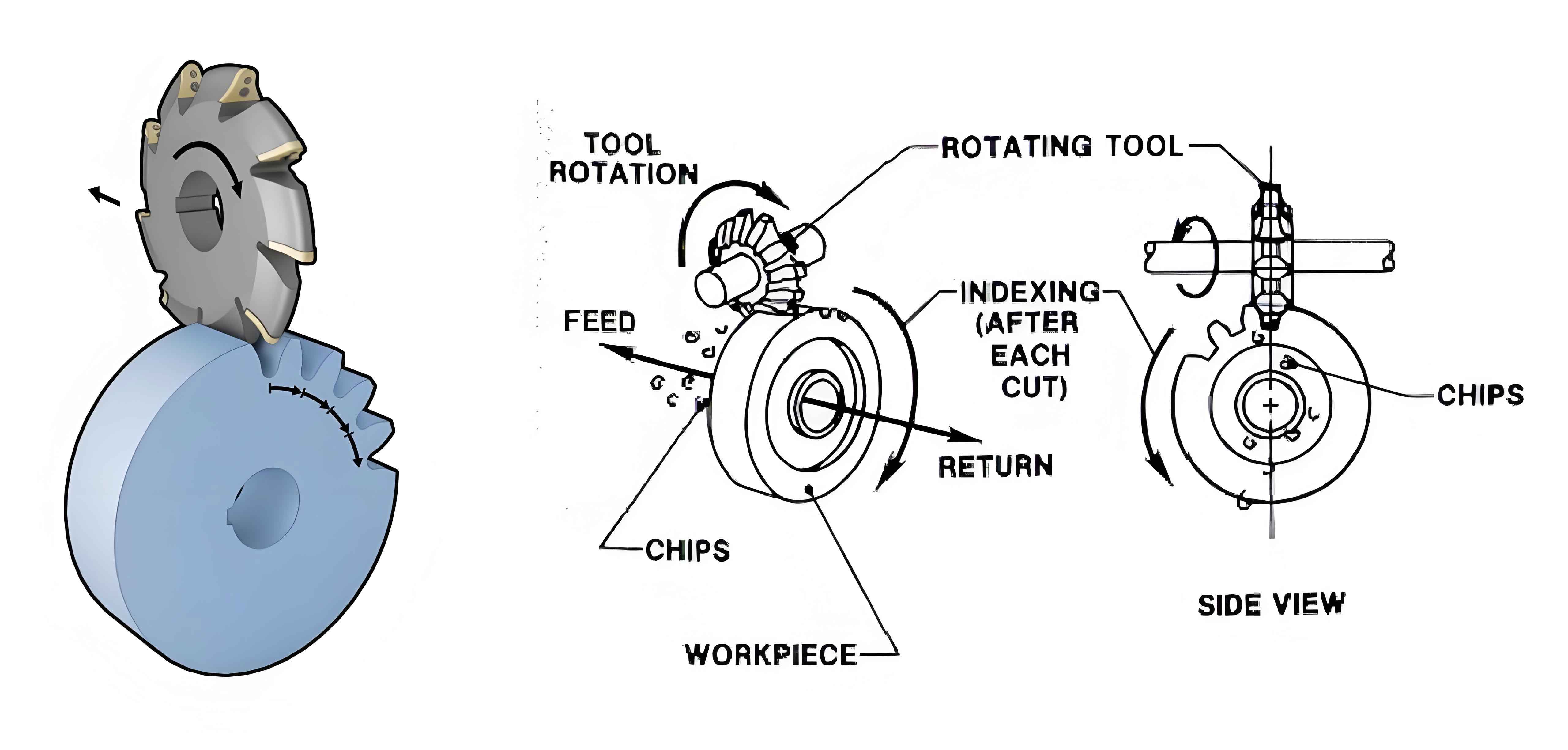

The electrical anti-backlash technology, with double-motor anti-backlash as a typical representative, can effectively improve the defects of traditional anti-backlash technologies, maintaining good transmission accuracy stability while eliminating backlash [3], and thus gradually replacing spring anti-backlash methods and mechanical anti-backlash methods as the mainstream anti-backlash technology. The double-motor anti-backlash device includes two motors, two reducers, two gears, and a rack. Two servo motors with the same drive parameters are connected to the reducers [4], and the reducers are connected to their respective drive gears. The two sets of gears and racks that mesh with each other jointly bear the load movement.

During the startup and reversal processes, the torque compensator distributes the torque to the servo motors in the drive system, causing them to withstand offset torques. Under the action of the offset torques, the two sets of gears and racks engage in meshing transmission. The meshing surfaces are the right tooth flanks of the driving wheel and the gear rack, and the left tooth flanks of the driven wheel and the gear rack. Therefore, the gear rack receives offset torques of equal magnitude and opposite directions, i.e., the resultant torque and resultant force are both zero. The swing of the gear rack loses its driving force, and its swing space is controlled [5], thereby achieving the purpose of eliminating backlash, ensuring transmission accuracy, and greatly improving its stability. The problem of decreased machine tool positioning accuracy caused by wear of mechanical parts is properly solved, so double-motor anti-backlash technology is adopted to achieve backlash elimination in fully CNC spiral bevel gear milling machines.

2. Motion Process Analysis of the Double-motor Anti-backlash Mechanism of the Milling Machine

2.1 Startup Process Analysis

The startup process of the double-motor anti-backlash mechanism of the milling machine is divided into four stages, with the output torques of the driving motor and the driven motor interacting with the offset torque in each stage to achieve the purpose of eliminating backlash.

Stage 1 (Speed Command ω = 0):

At this stage, the output torque of the main motor is M1, and the output torque of the driven motor is M2. The torques have the characteristics of being equal in magnitude and opposite in direction, and both numerically equal to the offset torque. M1 and M2 act on the main motor and the driven motor, respectively, causing the two sets of gears and racks to mesh on different side tooth flanks. The rack receives M1 and M2, which are equal in magnitude and opposite in direction, with a resultant torque of zero. The rack is in a static state, effectively preventing the rack from having freedom of movement in the backlash, thereby achieving the purpose of eliminating backlash.

Table 1. Startup Process Analysis (Stage 1)

| Parameter | Value | Description |

|---|---|---|

| Speed Command (ω) | 0 | Initial speed command |

| Main Motor Torque (M1) | Equal to Offset Torque | Torque applied to the main motor |

| Driven Motor Torque (M2) | Equal to Offset Torque but Opposite Direction | Torque applied to the driven motor |

| Resultant Torque | 0 | Resultant torque on the rack |

| Rack State | Static | Rack is prevented from moving |

Stage 2 (Speed Command ω > 0):

At this stage, the torque compensator distributes the offset torque to the main motor and the driven motor, with torques Md1 and Md2, respectively, but with Md1 > Md2 in magnitude, and the torques are in different directions. At this time, the resultant torque M on the rack is Md1 – Md2, pointing in the positive direction. The driving wheel and the driven wheel mesh with the rack on different side tooth flanks, causing the rack to move in the positive direction under the action of the resultant torque M.

Table 2. Startup Process Analysis (Stage 2)

| Parameter | Value/Description |

|---|---|

| Speed Command (ω) | > 0 |

| Main Motor Torque (Md1) | Greater than Driven Motor Torque |

| Driven Motor Torque (Md2) | Smaller than Main Motor Torque |

| Resultant Torque (M) | Md1 – Md2, positive direction |

| Rack Movement | Positive direction |

Stage 3 (Speed Command ω Increases but Does Not Reach Rated Value):

As the speed command continues to increase but has not reached the rated value, the output torque of the driven wheel, when superimposed with the offset torque, becomes zero, i.e., Md2 = 0, causing the driven wheel to disengage from the meshing surface and quickly cross the backlash, re-engaging with the same side tooth flank as the driving wheel. Afterward, the rack will only be acted upon by Md1 and continue to rotate in the positive direction.

Table 3. Startup Process Analysis (Stage 3)

| Parameter | Value/Description |

|---|---|

| Speed Command (ω) | Increasing but < Rated |

| Driven Motor Torque (Md2) | Superimposed with Offset Torque = 0 |

| Rack Movement | Continues in Positive Direction |

Stage 4 (Speed Command ω Increases to Rated Value):

At this stage, the output torques of the main motor and the driven motor, when superimposed with the offset torque, are both in the positive direction, causing the driving wheel and the driven wheel to mesh with the rack on the same side tooth flank. The torque compensator gradually withdraws the allocated offset torque, allowing the driving wheel and the driven wheel to jointly bear the load torque and drive the meshing transmission of the gear and rack.

Table 4. Startup Process Analysis (Stage 4)

| Parameter | Value/Description |

|---|---|

| Speed Command (ω) | Rated |

| Torque Superposition | Both Motors Positive |

| Rack Movement | Driven by Both Motors |

2.2 Reversal Process Analysis

The prerequisite for reversal in the dual-motor anti-backlash mechanism of the spiral bevel gear milling machine is that the speed command gradually decreases from its rated value. As this occurs, the torque compensator plays a crucial role in redistributing the offset torque between the main motor and the driven motor.

During this reversal process, the output torques of the two motors, when superimposed with the offset torque, are maintained in the positive direction. This ensures that both the driving wheel (active gear) and the driven wheel (passive gear) remain meshed with the rack on the same side tooth flank, thereby driving the rack to continue moving in its current direction.

As the speed command continues to decrease, the superimposed torque of the driven motor, Md2, gradually reduces. Eventually, the output torque of the driven motor, when combined with the offset torque, reaches zero. At this point, the driven wheel disengages from its current meshing surface and quickly crosses the backlash, re-engaging with the rack on a different side tooth flank from the driving wheel.

Meanwhile, the driving wheel continues to apply a positive torque (Md1) to the rack, causing it to move in the same direction, albeit with decreasing speed. As the speed command further decreases, the torque compensator allocates a reverse offset torque to the driven motor, forming a new reverse superimposed torque (Md2). However, at this stage, Md2 is less than Md1, meaning that the rack still moves in the positive direction under the influence of the forward torque.

Eventually, when the speed command drops to zero, the output torques of both the main motor and the driven motor equal the offset torque but in opposite directions. Consequently, the resultant torque acting on the rack is zero, causing the gear and rack to become locked and unable to move.

It is evident that during the reversal process of the dual-motor anti-backlash mechanism in the spiral bevel gear milling machine, when the speed command reaches zero, the main motor and the driven motor receive offset torques in the opposite direction to those during the start-up phase. As the speed command increases again, the operation of the offset torque follows a similar process to that of the start-up phase.

In summary, the torque compensator redistributes the offset torque during the reversal process to ensure that at least one set of gears remains meshed at all times, preventing the rack from moving freely within the backlash and thereby eliminating the backlash issue. This process ensures smooth and accurate transmission in the spiral bevel gear milling machine.