Abstract: As a special equipment for machining spiral bevel gears, the spiral bevel gear milling machine is prone to jamming issues due to backlash during the CNC machining process, leading to impact and vibration phenomena, which reduce gear machining accuracy. This paper compares anti-backlash technologies and constructs a double-motor anti-backlash method for the transmission system of a spiral bevel gear milling machine based on PMAC. The anti-backlash method is tested using a dual-motor drive application system with an IPC+PMAC motion controller. The results show that this method can effectively eliminate backlash and improve the stability of the entire CNC system. The use of a dual-motor servo anti-backlash method has certain reliability.

1. Introduction

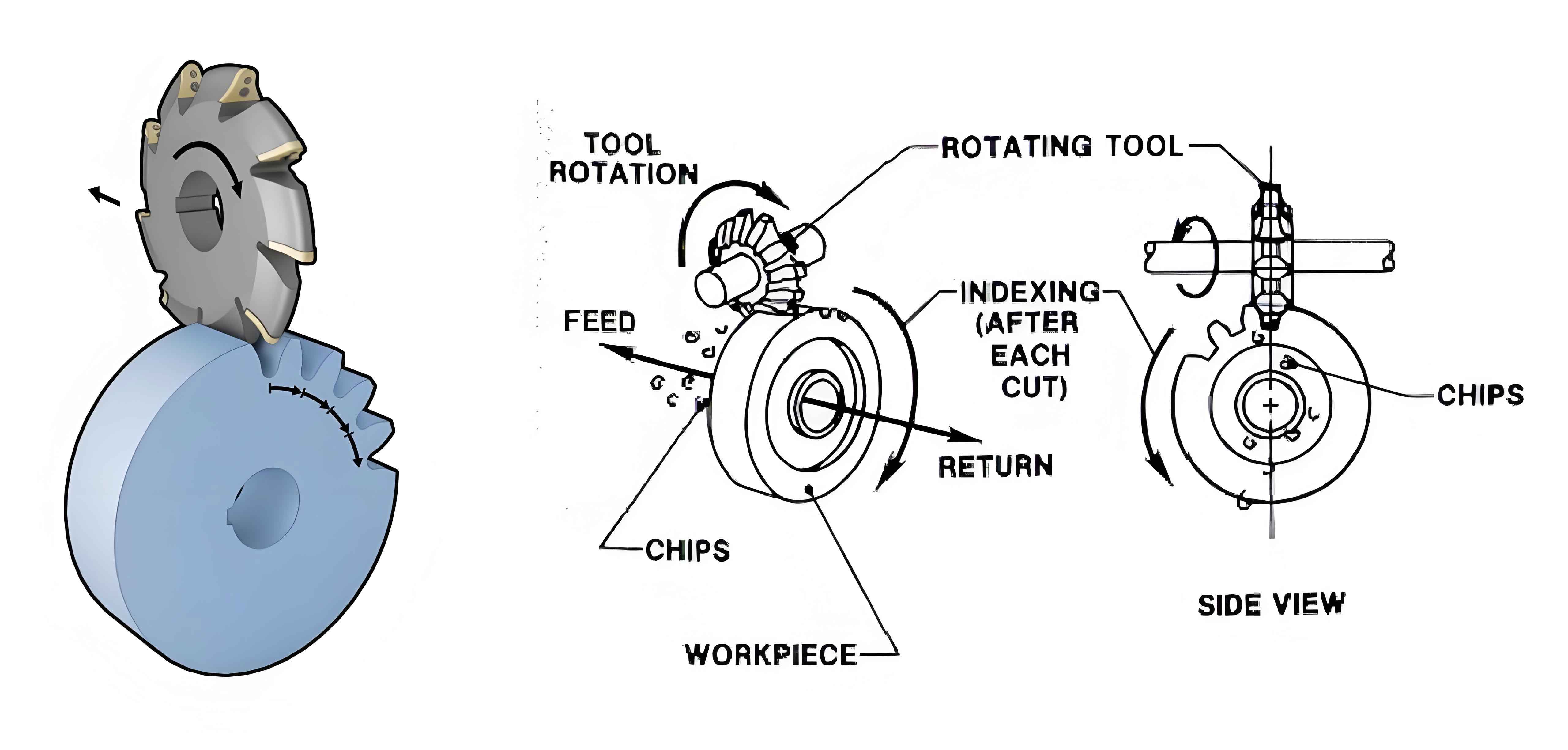

In the transmission mechanism of a fully CNC spiral bevel gear milling machine, to avoid jamming issues when the gear pair meshes, it is preferable to leave a certain gap between the gear teeth. However, precise control over the size of this gap cannot be achieved. With long-term meshing and wear in the transmission system, the backlash gradually increases, causing the linear relationship between the input of the driving gear and the output of the driven gear to become nonlinear. This results in reduced position control accuracy, intensified impact collisions between gear teeth, and subsequent oscillation of the entire transmission system. The machining accuracy of the milling machine and the stability of the servo system are significantly reduced.

To ensure the stability and high-precision transmission of the gear transmission system of the milling machine’s turntable, anti-backlash technology emerges. Anti-backlash technologies mainly include spring anti-backlash methods, mechanical anti-backlash methods, and electrical anti-backlash methods. Among them, the spring anti-backlash method is a traditional technology with a relatively simple structure but stringent requirements on the processing accuracy of gear racks and spring compression, making it unsuitable for precision CNC machines. Although the mechanical anti-backlash method uses a special elastic coupling to add a constant torque in advance on the coupling, causing the meshing gears to produce torques in opposite directions, thereby eliminating the backlash generated during transmission, its structure is complex, requiring specially made couplings and preload tools, and the stability of transmission accuracy is low.

The electrical anti-backlash technology, with double-motor anti-backlash as a typical representative, can effectively improve the defects of traditional anti-backlash technologies while maintaining good transmission accuracy stability. Therefore, it gradually replaces spring and mechanical anti-backlash methods as the mainstream anti-backlash technology.

The following sections of this paper provide a detailed analysis and experimental validation of the double-motor anti-backlash technology for CNC spiral bevel gear milling machines.

2. Movement Process Analysis of Double-Motor Anti-Backlash Mechanism of Milling Machine

The startup process of the double-motor anti-backlash mechanism of the milling machine is divided into four stages, with the output torques of the driving and driven motors interacting with the bias torque to achieve the purpose of eliminating backlash at each stage.

2.1 Startup Process Analysis

| Stage | Speed Command (ω) | Torque of Driving Motor (M1) | Torque of Driven Motor (M2) | Bias Torque Allocation | Movement of Rack |

|---|---|---|---|---|---|

| Stage 1 | ω = 0 | M1 = Bias Torque | M2 = -Bias Torque | Equal and Opposite | Stationary |

| Stage 2 | ω > 0 | Md1 > Md2 (Md1 > 0, Md2 < 0) | Bias Torque Allocated | Moves in Positive Direction | |

| Stage 3 | ω > 0 (Increasing) | Md1 Continues to Increase | Md2 = 0 (Disengaged) | Continues Moving Positively | |

| Stage 4 | ω = Rated Value | Both Motors Positive | Bias Torque Reduced | Shared Load Moment |

2.2 Reversal Process Analysis

The reversal process begins when the speed command gradually decreases from the rated value. The torque compensator reallocates the bias torque on the driving and driven motors, superimposing their output torques with the bias torque to keep the superposition torque in the positive direction. This ensures that the driving and driven wheels engage with the rack on the same side to drive the rack in the forward direction. As the speed command continues to decrease, the superposition torque of the driven motor gradually decreases until it becomes zero, disengaging the driven wheel and allowing it to quickly cross the backlash to re-engage with the same side tooth surface as the driving wheel. The rack then continues to move in the positive direction under the action of the superposition torque of the driving motor.

2.3 Comprehensive Analysis of Startup and Reversal Processes

Throughout the startup and reversal processes of the double-motor anti-backlash mechanism, the bias torque allocated by the torque compensator, superimposed with the output torques of the driving and driven motors, acts on the driving and driven wheels. The purpose is to ensure that at least one set of gear racks is engaged during transmission, preventing the rack from moving freely within the backlash and thus eliminating the backlash issue.

3. Experimental Validation of Double-Motor Anti-Backlash Technology

3.1 Experimental Platform Setup

| Component | Specification/Model | Function |

|---|---|---|

| IPC | Industrial Personal Computer | Upper computer for control and communication |

| PMAC | Programmable Multi-Axis Controller | Lower computer for motion control |

| Controller | CK3E | Connects IPC and PMAC |

| Servo Motor | PRHD2 DC Servo Motor | Provides driving force |

| Drive | CDHD Drive | Powers and controls the servo motor |

| Communication Protocol | EtherCAT | Facilitates high-speed data exchange |

The experimental platform uses an IPC as the upper computer and PMAC as the lower computer, connected through a controller (CK3E). The IPC communicates with the controller via information transmission and human-computer interaction, while the controller serves as the lower computer’s controller. The configuration of IPC+CK3E enables the dual-motor drive application system to have two relatively independent central processors, providing high operational efficiency and fast response speed. The combination of the CDHD drive and PRHD2 DC servo motor offers excellent servo performance, high power density, and simple debugging, making it easy to achieve quick setup and highly economical.

3.2 Experimental Results and Analysis

The experimental results demonstrate that the proposed double-motor anti-backlash method effectively eliminates backlash, improving the positioning accuracy and stability of the CNC spiral bevel gear milling machine. By precisely controlling the output torques of the driving and driven motors and allocating the bias torque through the torque compensator, the engagement between the gear racks is maintained, preventing free movement within the backlash.

The following graph illustrates the improvement in positioning accuracy achieved using the double-motor anti-backlash method:

(Insert a graph here showing the comparison of positioning accuracy before and after applying the double-motor anti-backlash method)

The graph clearly shows that after implementing the double-motor anti-backlash method, the positioning accuracy of the milling machine significantly improves, demonstrating the effectiveness of the proposed approach.

Conclusion

In conclusion, the double-motor anti-backlash technology for CNC spiral bevel gear milling machines presents a significant advancement in eliminating backlash and improving the overall stability and accuracy of the machining process. By leveraging the precise control capabilities of modern servo motors and motion controllers, the proposed method ensures continuous and accurate engagement between gear racks, minimizing the impact of backlash on machining accuracy. The experimental results validate the effectiveness and reliability of the double-motor anti-backlash method, making it a promising solution for enhancing the performance of spiral bevel gear milling machines.