Before the 1990s, the research and production of gear forging were mainly based on physical simulation. That is because the numerical simulation method at that time was not perfect in simulating plastic deformation, and was not ideal in predicting metal deformation law and accurately calculating stress, strain, temperature and other parameters.

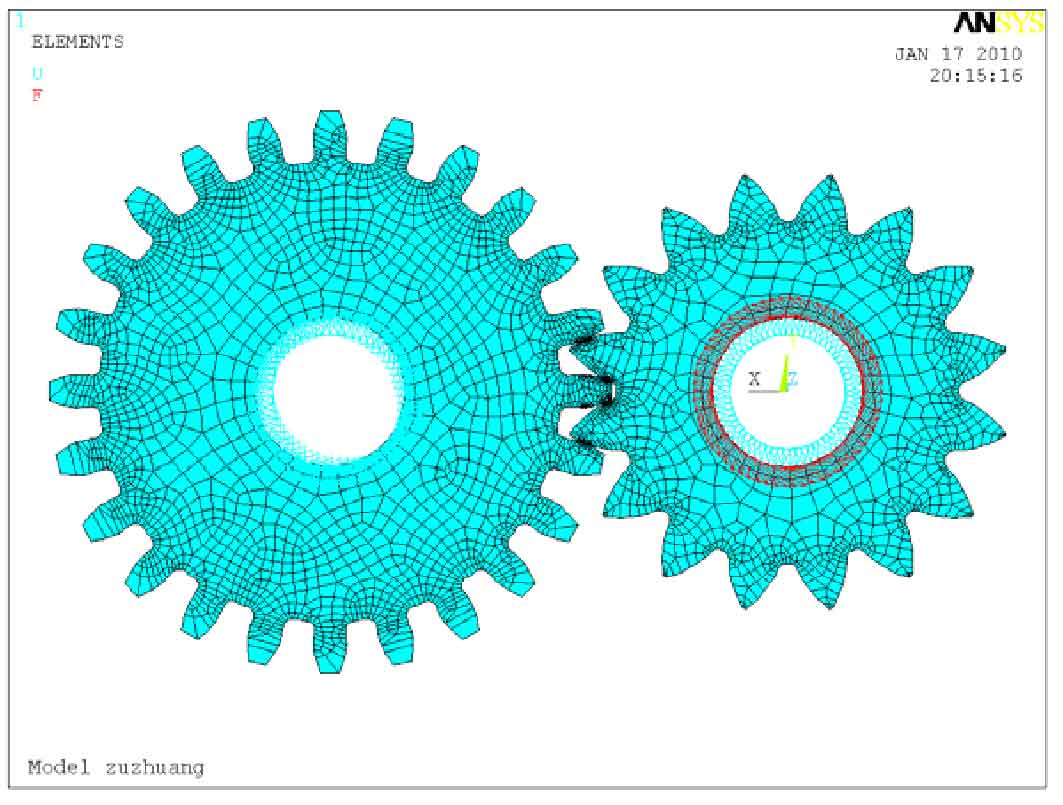

Hung hsiou Hsu used the upper bound element method to study the effects of friction, tooth number and other parameters on forming force and metal filling effect. Jougung Choi et al. Studied the forging process and die design of spur gears and triangular internal fine teeth by using the upper bound element method. J. H.SONG et al. Studied the cold forged spur gear, and analyzed the influence of modulus and tooth number on material deformation mechanism by numerical simulation method. Herian t et al. Optimized the gear tooth geometry with the finite element software ANSYS, obtained the analyzed die stress diagram and the optimized tooth shape, and carried out the fatigue test on the gear.

M. H.sadeghi et al. Studied the forging process of spur and helical gears by using the upper bound element method, obtained the metal flow law and deformation load in the forming process, and studied the effects of parameters such as the number of teeth, modulus, friction and the diameter of the blank inner hole on the forming load. The results show that the forming load can be reduced by reducing the friction coefficient, the number of teeth, the modulus and the diameter of the blank inner hole. Doege et al. Studied the spur bevel gear with the finite element numerical simulation method, and obtained the relevant data of the gear tooth profile radial and axial shrinkage during the cooling process after forging. The forging process of spur bevel gear is simulated by numerical simulation method, and the load stroke curve of the forging process is obtained.