The failure gear is the first gear of the gearbox of the truck, which is made of the carburizing steel. When it is tested on the bench, it will break if it does not meet the design requirements.

According to the fracture morphology, it can be concluded that the fracture of the gear is caused by high stress. The fracture of the driving gear center is basically dimple, and the passive gear has quasi cleavage fracture morphology, which shows that the driving gear has better toughness but lower strength. The microhardness of the driving gear is lower than that of the passive gear. There are net cementite precipitates in the carburized layer of two gears, which will make the surface toughness lower, so that it can not stand the start-up impact stress during operation. This fracture accident is caused by the first fracture of the driving gear, and then the collapse of the passive gear, so the traces of bruise can be seen on the passive gear. Therefore, it can be considered that the failure of gear is caused by improper carburizing process control (improper heat treatment).

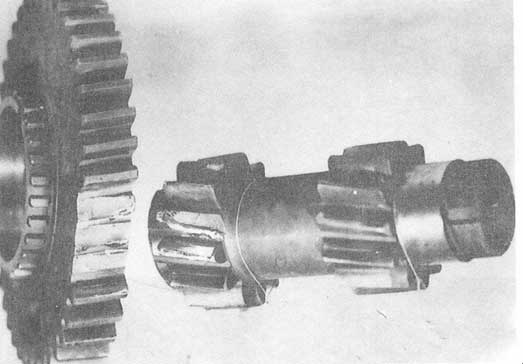

The macroscopic appearance of the gearbox gear after the tooth break.

Fracture morphology of passive gear. Along the root fracture, the fracture morphology is similar to that of the driving gear, and several teeth near the broken teeth have small pieces of crack and bruise in varying degrees.