With the continuous development of the automobile industry, enterprises gradually adopt light and fuel-efficient front wheel drive vehicles to replace most heavy and rear wheel drive vehicles. This kind of car needs to use parts that are as small as possible and as light as possible. After effectively solving the technical problems of reverse transmission efficiency and variable speed ratio of rack and pinion steering gear, it has been widely used in cars below intermediate level and light and mini trucks with independent front suspension. Rack and pinion steering gear is mainly composed of steering gear, steering rack, steering gear housing and other parts. Compared with other steering gears, rack and pinion steering gear has the following advantages: less frame parts; Small volume; High transmission efficiency; Light weight; The steering transmission mechanism is simplified and the manufacturing cost is low; Without steering rocker arm and tie rod, the steering wheel angle can be increased; Using the compression spring to compress the steering gear and steering rack can reduce the clearance between teeth, improve the stiffness of rack and pinion steering gear and reduce the negative impact during operation.

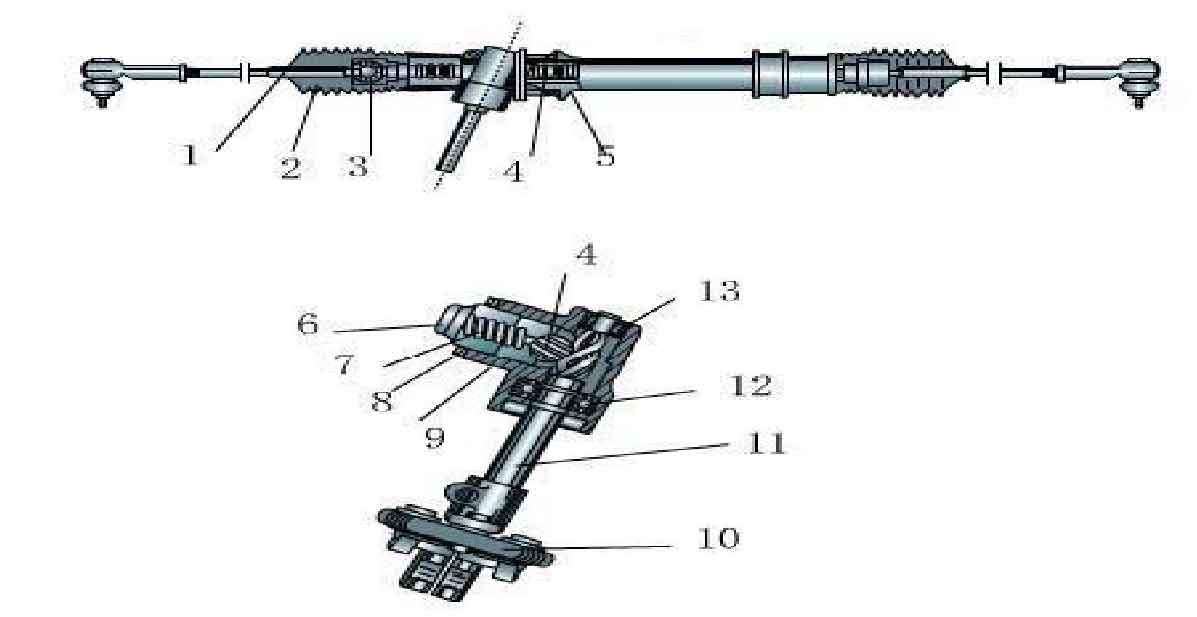

The basic structure of automobile rack and pinion steering gear is composed of a pair of meshing steering gears and steering racks. The steering gear and gear shaft are made into one, which is called steering gear shaft. When the steering gear shaft drives the steering gear to rotate, the rack makes a linear motion to drive the steering tie rod, which can change the direction of the steering wheel. The explosion diagram of the basic structure of automobile rack and pinion steering gear is shown in Figure 1.

According to different output modes, the automobile rack and pinion steering gear is divided into middle output rack and pinion steering gear and two end output rack and pinion steering gear. The structure of the rack and pinion steering gear output at both ends is shown in Figure 2.

The working principle of the rack and pinion steering gear output at both ends is as follows: the steering gear is fixed on the vehicle body through the housing, the steering gear shaft is installed in the housing, the upper shaft is connected with the universal joint, the lower steering gear is meshed with the steering rack, and both ends are connected with the tie rod. The compression spring presses the steering rack into the steering gear and adjusts the compression spring through the adjusting screw plug. The rotation of the steering wheel drives the steering gear to rotate, so as to move the steering rack, drive the tie rod to rotate, so as to drive the steering knuckle to rotate, which can change the direction of the car.

The middle output rack and pinion steering gear is connected with the tie rod in the middle of the steering rack, and one end of the steering rack is connected with the tie rod through the bracket. The structure is shown in Figure 3.