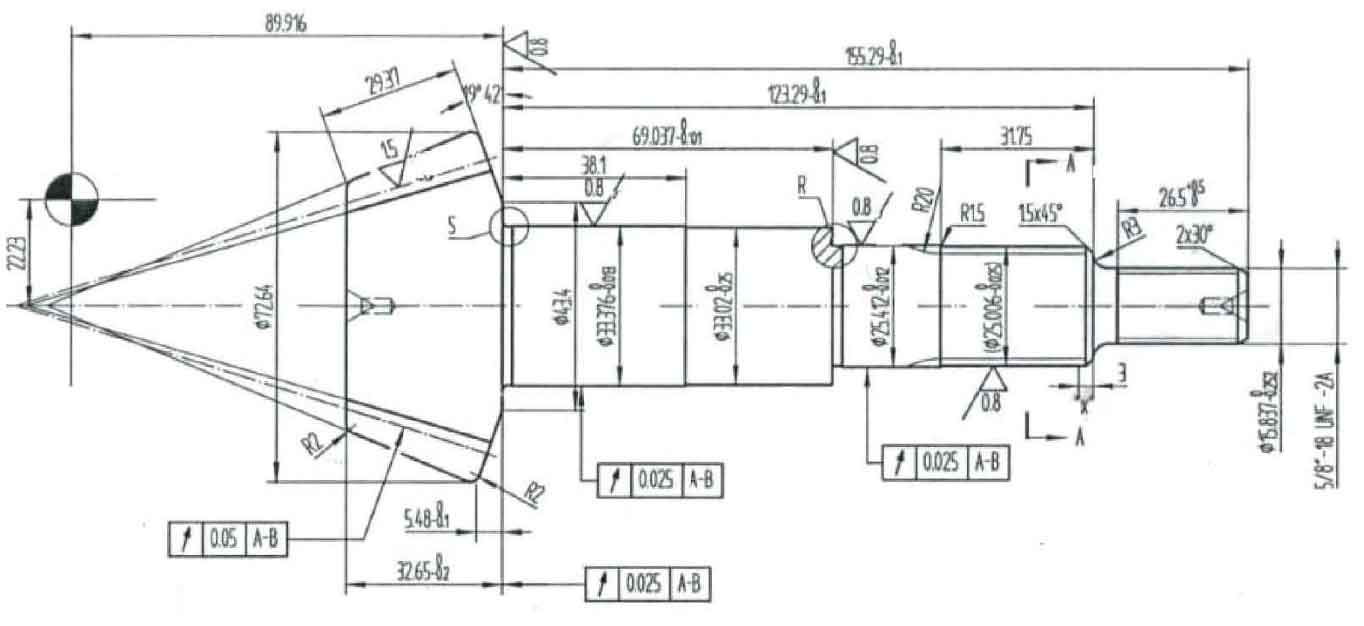

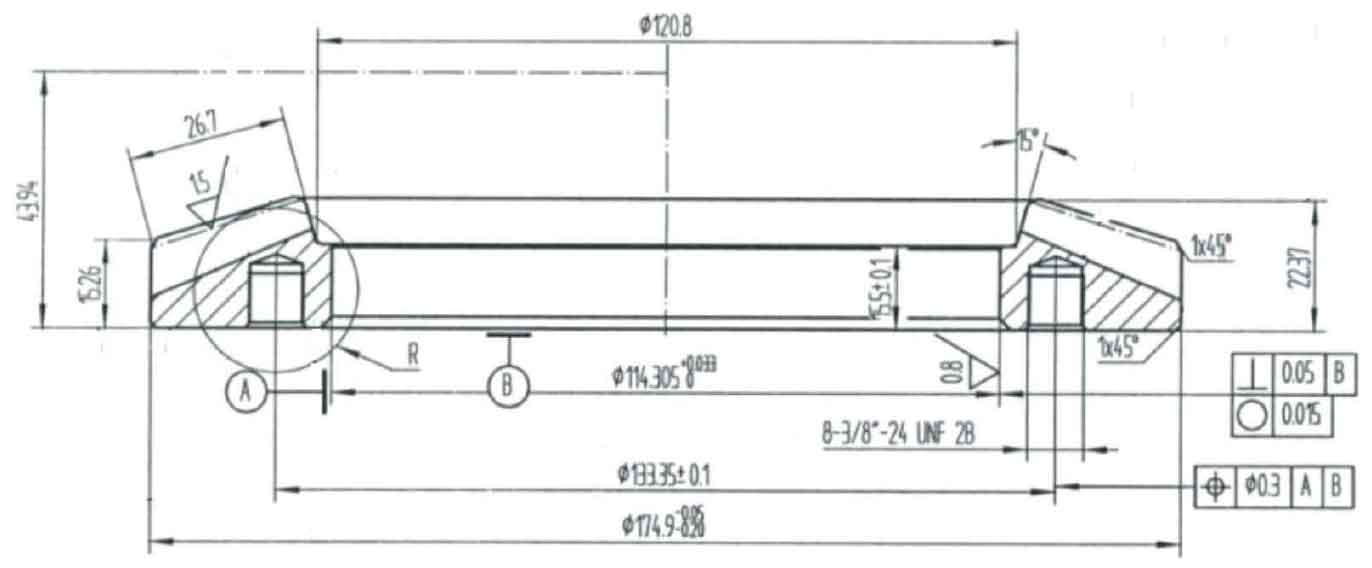

Based on the existing forming methods of driving and driven bevel gear blank of automobile rear axle, a new composite forming process is proposed. On the premise of ensuring the forging quality of driving and driven bevel gear blanks, this composite forming process can combine a variety of forming methods to cut the driving and driven bevel gear blanks at one time and produce them at the same time, so as to save materials and improve production efficiency. The parts drawing of driving and driven bevel gear blank of automobile rear axle provided by a foreign automobile factory is shown in Figures 1 and 2 (unit: mm; material: 20CrMoH).

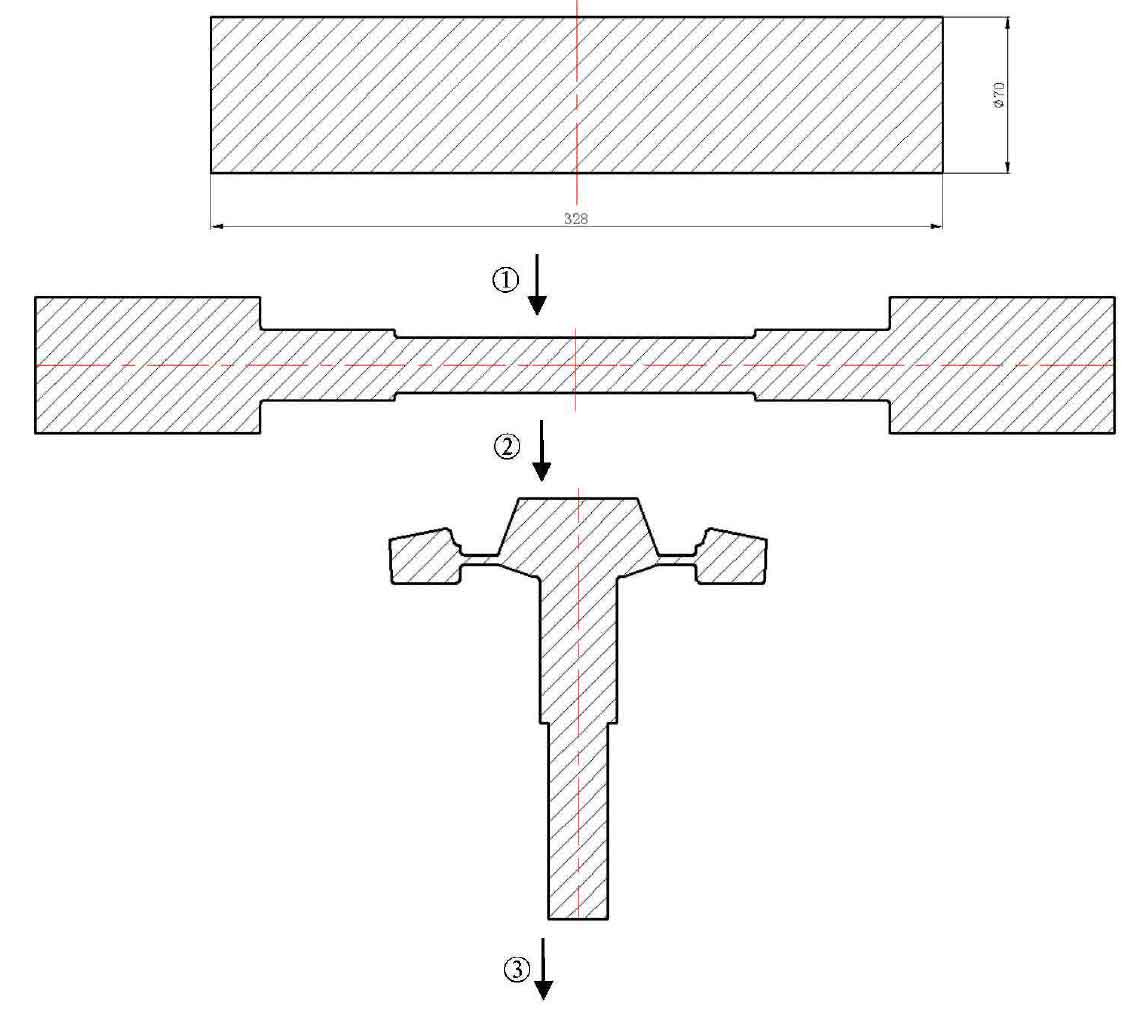

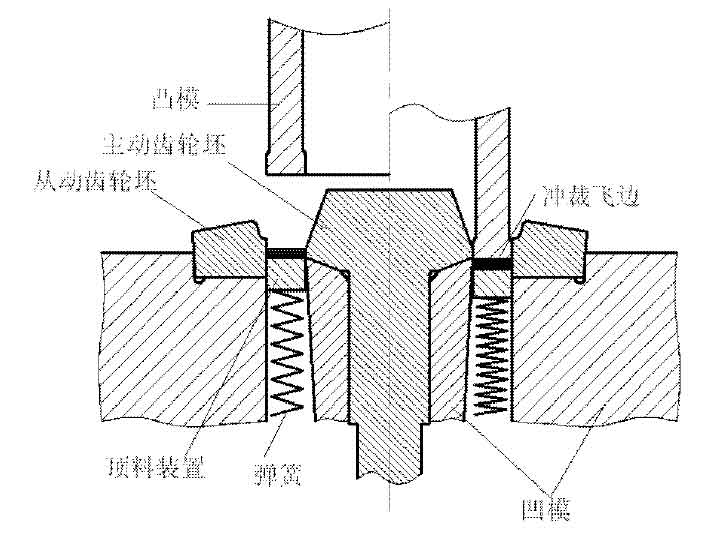

The feasibility of the proposed composite forming process is verified mainly through numerical simulation, and the die design parameters are provided for the actual production. The crown part of the driving bevel gear blank and the driven bevel gear blank are formed by cross wedge rolling and closed die forging (as shown in Figure 3). The forming process of the composite forging is simulated by using the simulation software. Through the simulation, the best forming process parameters are found, and the newly proposed composite forming process scheme is tested and verified, Whether the bevel gear blank without obvious defects can be forged (such as folding, crack, etc.); And whether the forged bevel gear blank can meet the technical and quality requirements. Analyze whether the metal flow is reasonable, the filling condition, and the die stress. If the qualified forgings can be obtained, the best forming parameters can be obtained through repeated simulation.