The positioning of automobile gear hob should ensure that the whole aperture and end face are required to be used. Each position is based on the shaft, so as to ensure that all hob teeth complete the part of the tooth profile required for machining. This assembly relationship limits the position of the hob.

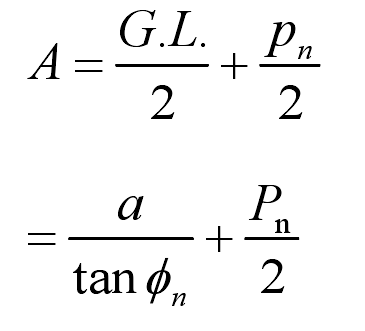

When the teeth of the automobile gear hob are used with thick (small) teeth at both ends, it means the end of the hob rotation. The small teeth on both sides of the automobile gear hob must be cut before the tooth groove area. Therefore, in the adjustment of automobile gear hobbing, it should be ensured that the small teeth at both ends do not directly participate in cutting, so as to prevent the small teeth from collapsing due to overload. The position of small teeth of automobile gear hob changes with the rotation of hob. Pay attention to the change of angle and position during installation and use. The minimum set length a can be approximately expressed by the following formula whether it is straight tooth or oblique tooth:

Where, G.L. = maximum generation length;

A = minimum set length on hob axis;

A = hob tip height;

PN = diameter pitch

φ N = pressure angle

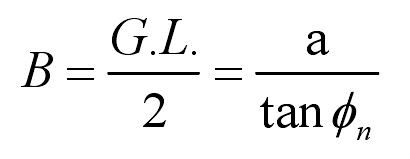

When the other end of the automobile gear hob is used for cutting, there are enough teeth to ensure the completion of cutting. After the tool shifting of automobile gear hob is completed, it is still necessary to ensure the maximum use of the last row of teeth. The minimum setting length B should be at least:

B = the minimum distance from the end tooth when the automobile gear hob is out

The maximum tool shifting length of automobile gear hob is the hob tooth length minus (a + b).