The dynamic excitation caused by the time-varying characteristics of meshing stiffness during gear meshing is called stiffness dynamic excitation of gear meshing, also known as stiffness excitation. This kind of excitation is one of the most important and basic dynamic excitation in gear transmission system. This section will explain the mechanism of rigid excitation.

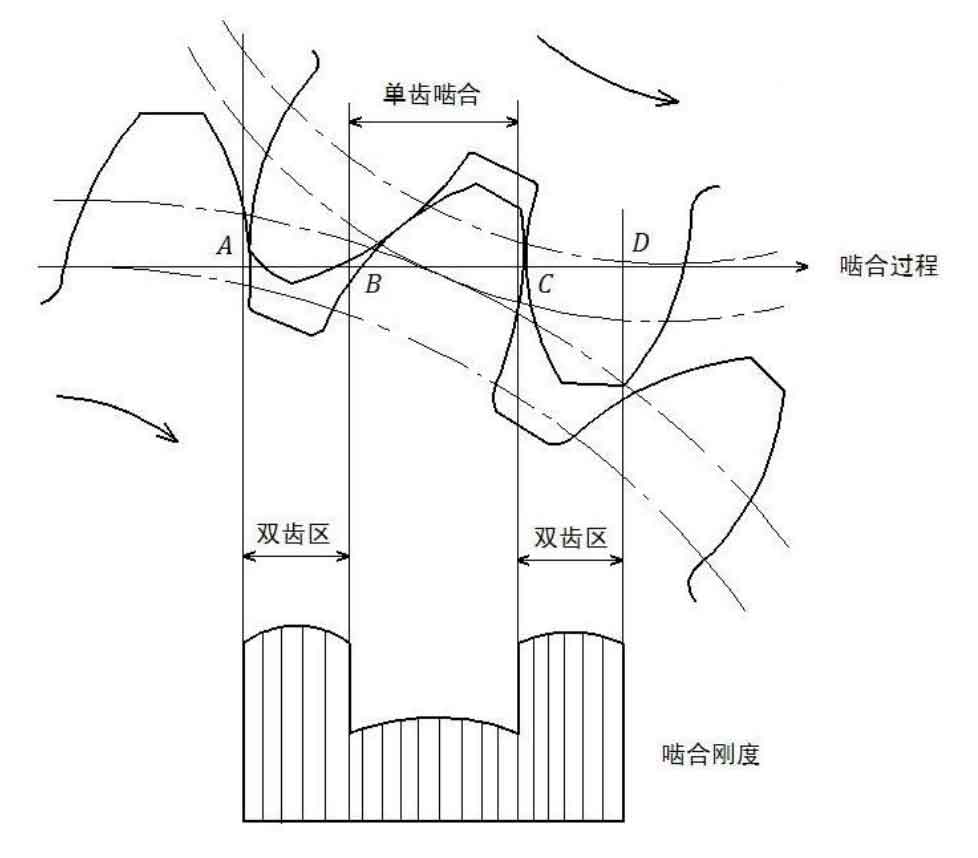

Taking a cylindrical gear (spur gear) as an example, if the coincidence degree of the gear is set, the torque transmitted by the spur gear remains unchanged. In this way, in the process of spur gear meshing, sometimes a pair of teeth participate in meshing, and sometimes two pairs of teeth participate in meshing. Accordingly, in the meshing area of single tooth pair, the meshing stiffness of spur gear is small and the elastic deformation during meshing is large; In the area where two pairs of teeth participate in meshing, because the two pairs of teeth bear the load together, the meshing stiffness of spur gear is increased, and the elastic deformation caused by meshing is small. Therefore, in the continuous rotation process of spur gear, with the continuous and alternating change of the number of teeth involved in meshing, the elastic deformation of teeth will also change periodically, resulting in the periodic change of spur gear circumferential speed, resulting in the vibration of spur gear transmission system. As shown in Figure 1, in the meshing area A-D, there are single tooth pair meshing area and double tooth pair meshing area at the same time, When the two zones alternate, the meshing stiffness of the gear teeth will have a sudden change.

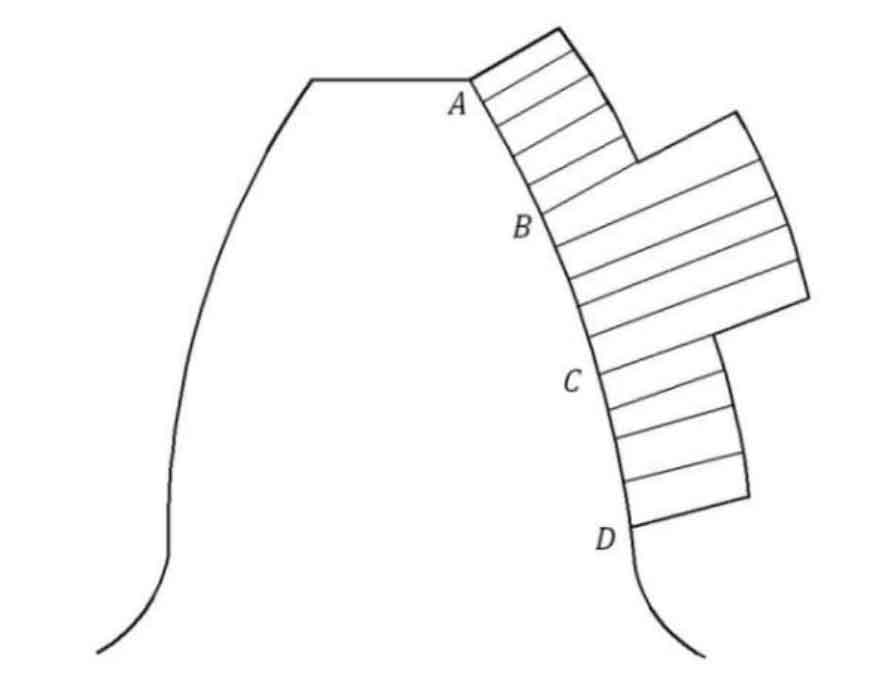

On the other hand, in the process of gear tooth meshing, due to the alternation of single tooth meshing and double tooth meshing, the load originally borne by two pairs of gear teeth will suddenly become borne by one pair of gear teeth, or the load originally borne by one pair of gear teeth will suddenly become borne by two pairs of gear teeth. As shown in Figure 2, the load is large in section B-C of single tooth area, However, the load is small in the A-B section and C-D section of the double tooth area. In this way, the sudden change of load during spur gear meshing will also produce dynamic excitation to the spur gear transmission system.

For helical cylindrical gear transmission system, although the tooth pairs involved in meshing do not change suddenly in the process of meshing, the changes of meshing stiffness and load are also periodic, which will also produce dynamic excitation to spur gear transmission system.

To sum up, the stiffness excitation of spur gear transmission system is mainly caused by the periodic change of meshing stiffness caused by the alternation of single tooth pair meshing and double tooth pair meshing during spur gear meshing. On the other hand, the time-varying characteristics of the meshing stiffness of spur gears during meshing are reflected in the time-varying characteristics of the elastic force term between gears in the spur gear dynamic analysis model. Therefore, from the basic nature, the stiffness excitation of spur gear transmission system is actually a kind of parametric excitation, and the dynamic problem of spur gear transmission system is essentially a kind of parametric vibration problem.

Generally speaking, the error free spur gear is called the ideal spur gear. The transmission error of the ideal spur gear does not consider the manufacturing error of the spur gear, but only the static transmission error caused by the elastic deformation of the gear teeth due to load. This transmission error is only related to the design of the spur gear, so it is called the design transmission error, Because the transmission error at this time actually includes stiffness excitation, the stiffness excitation of spur gear can be studied by discussing the design transmission difference and properties of ideal spur gear. On the other hand, the stiffness excitation is periodic, and the design transmission error of ideal spur gear can also be expressed as a periodic function. Therefore, if it is expanded into Fourier series and its spectral characteristics are determined, the stiffness excitation of gear teeth can be further discussed in the frequency domain.