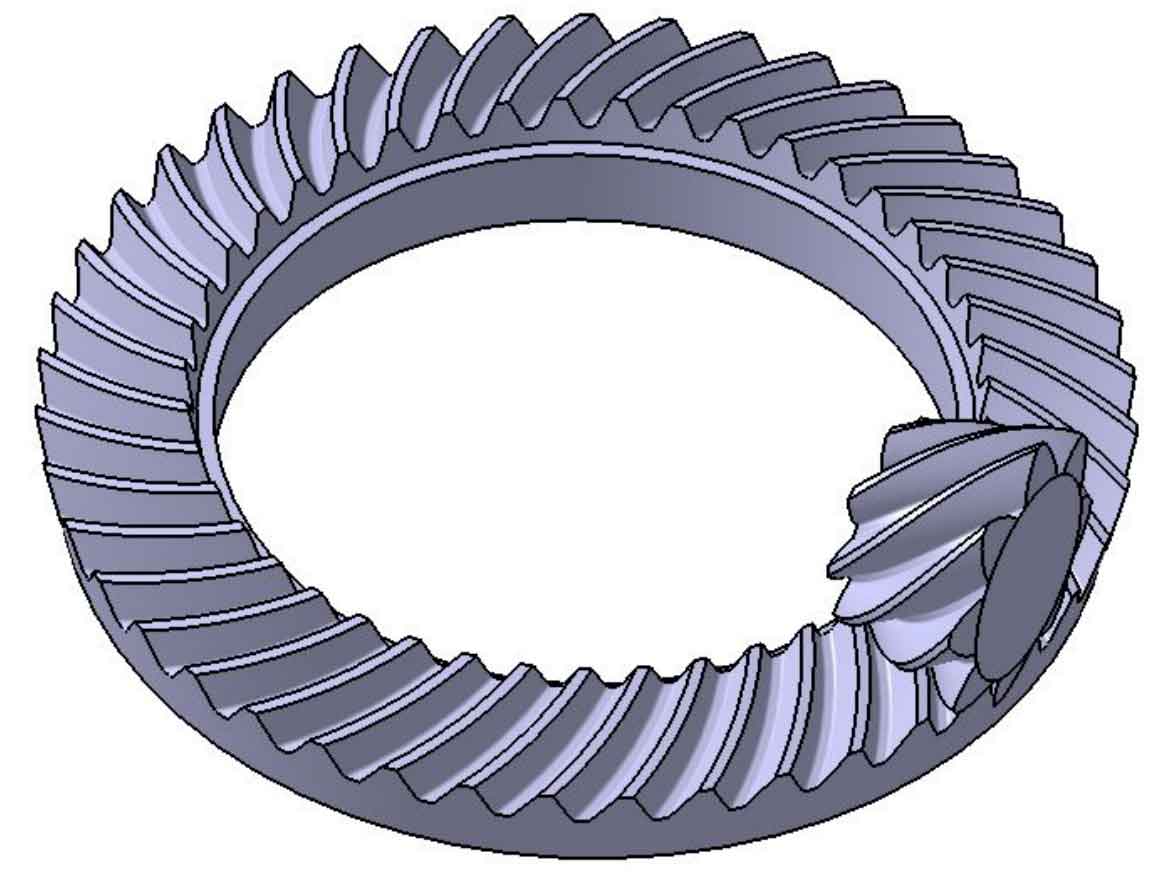

When the hypoid gear of the main reducer of the drive axle works in practice, the bending stress of the hypoid gear tooth root will be affected by the deformation of the hypoid gear support shell. In order to fully reflect the actual stress state of hypoid gear of the drive axle, the whole finite element model of the drive axle is established in this paper. In order to reduce the computational complexity of the finite element model, ABAQUS substructure model is used to replace the supporting shell components, so that only the degree of freedom of the connection position between the substructure model and the outside can be retained, and the internal node information of the substructure can be obtained by linear superposition of the external node information, which greatly improves the computational speed of the overall model.

Through ABAQUS / standard, the bending stress prediction model of the hypoid gear of the drive axle is established. The results show that due to the influence of the deformation of the drive axle, when the drive axle inputs a large load, the hypoid gear appears abnormal edge contact, which increases the bending stress of the tooth root when the hypoid gear enters the mesh. In order to verify the model, the bending stress of the hypoid tooth root of the drive axle was measured and compared with the predicted results. The results show that the root stress of hypoid gear is basically consistent with the test results.

According to the stress prediction results of hypoid gear tooth root, this paper establishes the bending fatigue prediction method of drive axle hypoid gear, and compares the prediction results with the bench test. The results show that the established model can accurately predict the fatigue life of drive axle gear. This paper studies the influence of four typical installation deviations on the bending stress and bending fatigue of hypoid gears. The results show that the bending stress and bending fatigue life of hypoid gear tooth root are sensitive to the installation cross angle deviation of hypoid gears, followed by the installation offset deviation, the axial installation deviation of pinion gears, and finally the axial installation deviation of large gears. The design of hypoid gear needs to strictly control the installation angle deviation. The contact and tooth root bending stress of hypoid gear can be improved by adjusting the axial installation deviation of large gear.