Hypothetical generating wheel is usually used to explain the machining process of bevel gear. It is a virtual bevel gear formed by the motion track of the blade. That is, in the process of gear cutting, assuming that the hypothetical plane bevel gear engages with the cut bevel gear without clearance, the whole cutting process of the bevel gear is like the meshing process of a pair of bevel gears, and the cutting surface of the cutter head and the machined tooth surface are a pair of completely conjugate surfaces.

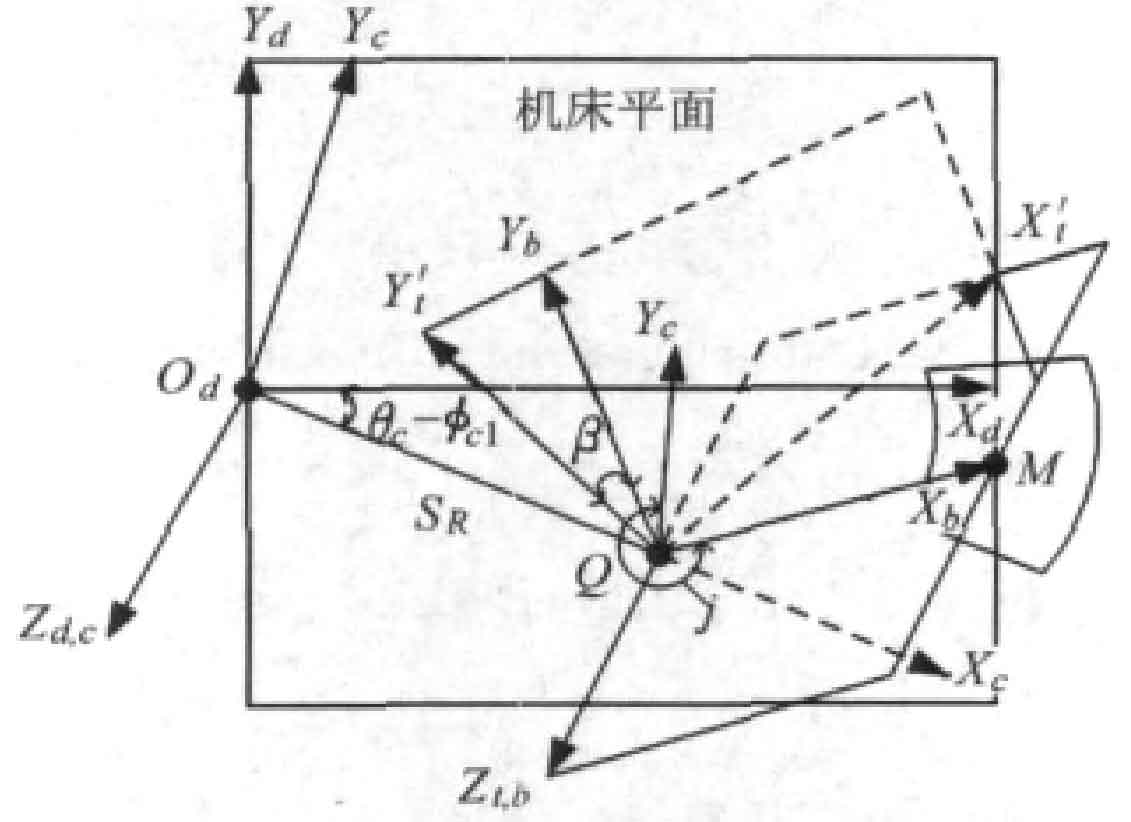

As shown in the figure, the production wheel forms a coordinate system. SD is the coordinate system fixedly connected with the production wheel, and Sb and SC are the auxiliary coordinate system. Point q is the tool tilt mechanism:

The center point on the cutting plane. The forming wheel equation is:

Of which:

Where:

β– Tool angle

Exz — tool eccentricity

φ E — tool positioning angle

SR — radial distance of shaking table

J — knife angle

θ C — initial angle of shaking table

Φ C1 — shaking table angle

Φ The relationship between C1 and tool angle is:

Where:

ZP — number of teeth of bevel gear