By using the professional heavy gear simulation analysis software, combined with the actual measurement parameters and working condition parameters, the dynamic load simulation analysis of all heavy gears is carried out. Based on the analysis results, the optimal design scheme that is closer to the actual working condition is obtained, and the tooth profile is optimized.

(1) State simulation analysis

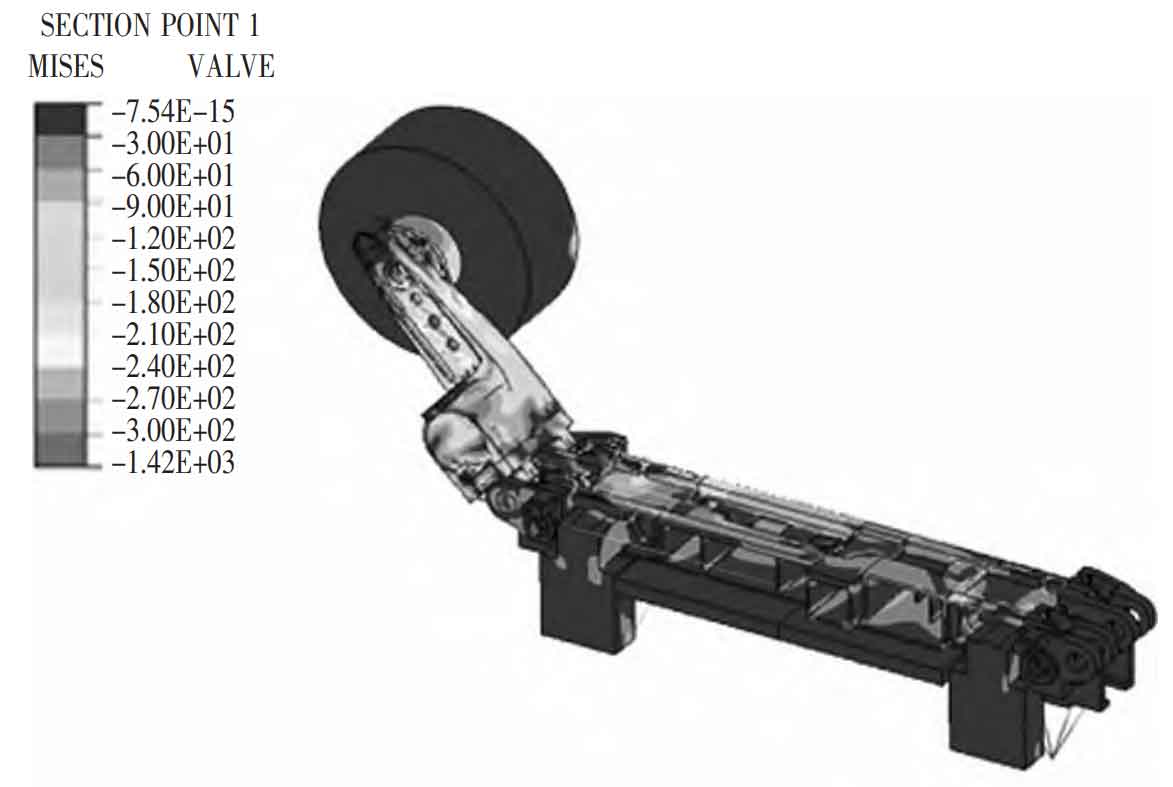

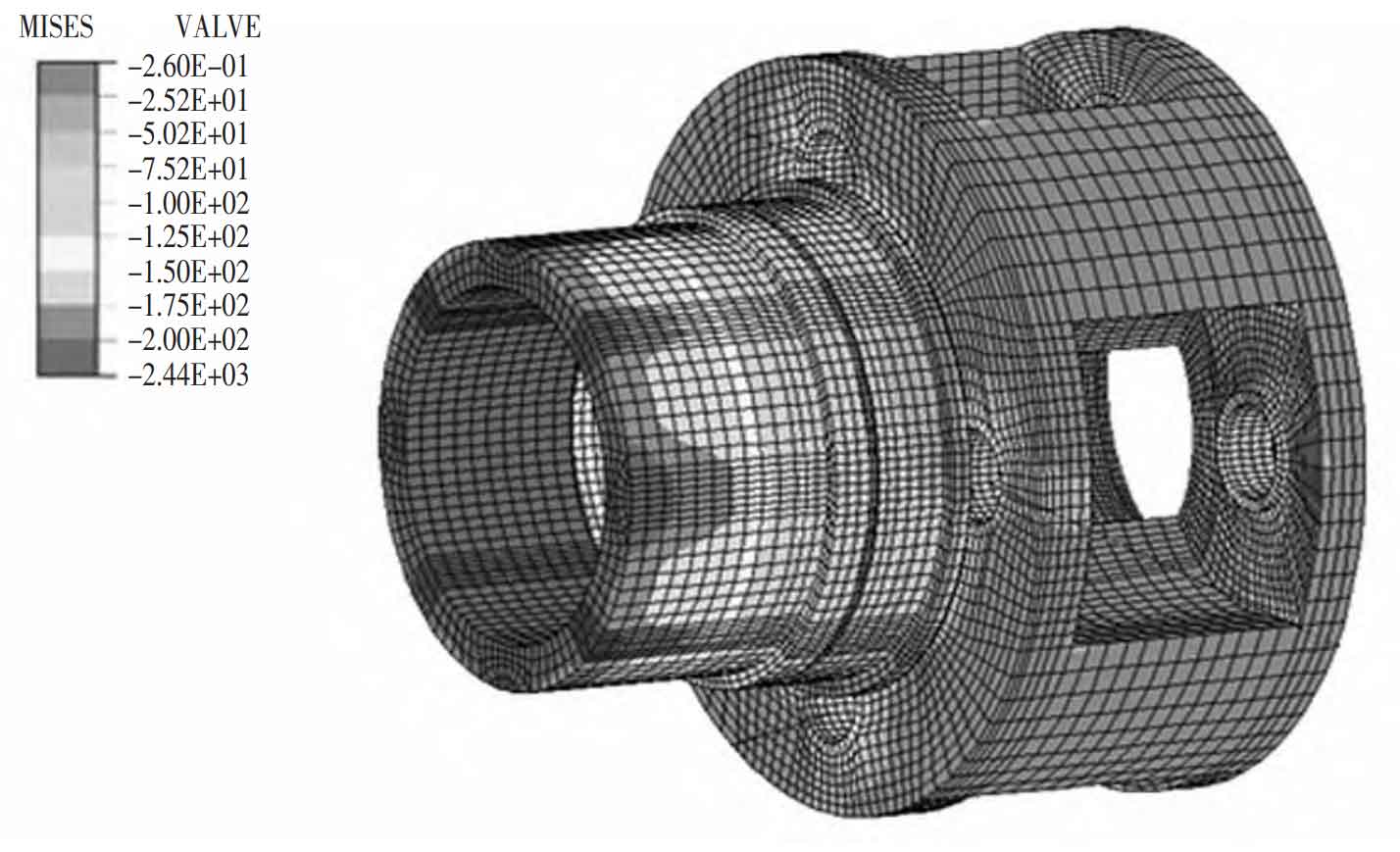

Working condition parameters of rocker arm: reduction ratio 47.225, motor power 750 kW, rotating speed 1 475 r/min, service factor 2.0, rated torque 229.32 kN, maximum torque 458.64 kN. The simulation effect of software related to the whole machine, rocker arm and key transmission parts is shown in the figure.

(2) Optimize design and shape modification

Under the action of load, the shaft of heavy gear will produce elastic deformation of varying degrees. At the same time, this load will also cause deformation of the box. The superposition of the above multiple deformation actions will cause impact, vibration and eccentric load in the meshing process of heavy gears. For this reason, all teeth are modified at both ends to prevent the tip of the tooth surface from contacting.

If necessary, the tooth profile modification is used to compensate the mesh deviation caused by the deformation of the shaft on the mesh surface, so that the tooth mesh surface is evenly distributed along the tooth width under normal load. At the same time, in order to avoid collision impact in the initial meshing stage and the final meshing stage, the tooth top and root shall adopt corresponding trimming treatment to improve the power transmission capacity and reduce friction and noise.