In view of the universality of FZG gear gluing test, FZG gluing test gear is selected, and GB/Z 6413 1、 GB/Z6413. 2 and HB/Z 84 4 Calculate the body temperature, average flash temperature and tooth surface temperature. The test involute cylindrical gear pair is shown in Figure 1. The material of the involute cylindrical gear pair is carburized steel 18CrNiMo7-6. Calculate the tooth surface temperature under different torque, oil temperature, modulus and rotational speed, and compare and analyze the calculation results of the three standards. As a flash of high temperature can lead to gluing, GB/Z 6413 The tooth surface temperature of 1 is the sum of the body temperature and the maximum flash temperature.

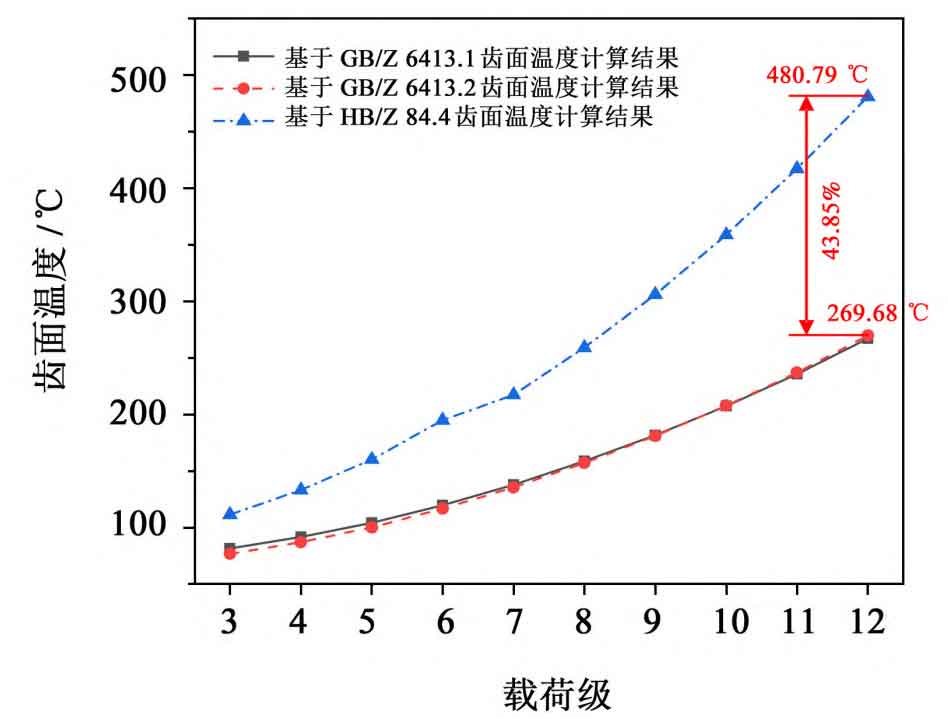

Select the torque at FZG 3~12 load levels and calculate the body temperature, average flash temperature and tooth surface temperature in the three standard calculation methods. The calculated results of tooth surface temperature based on three criteria are plotted in Figure 2. It can be found that HB/Z 84 The calculated result of tooth surface temperature of 4 is significantly higher than that of GB/Z 6413 1 and GB/Z 6413 2, and the difference of calculation results increases with the increase of load level. When FZG load level is 12, HB/Z 84 The tooth surface temperature calculation result of 4 is the same as that of GB/Z 6413 The maximum difference of 2 is 43 85%。 The main reason is HB/Z 84 Average friction factor in 4 μ Mc is 0 114, instead of GB/Z6413 2 The calculated average friction coefficient is 0 058, average friction coefficient of HB/Z84. 4 μ M ratio GB/Z 6413 2 high 49 1%, resulting in HB/Z 84 4. The calculated result of tooth surface temperature is higher than GB/Z6413 2。 Under different torques, GB/Z 6413 1 and GB/Z6413 2. The error of tooth surface temperature calculation results is not more than 5%, indicating that flash temperature method and integral temperature method do not lead to significant difference in calculation results.

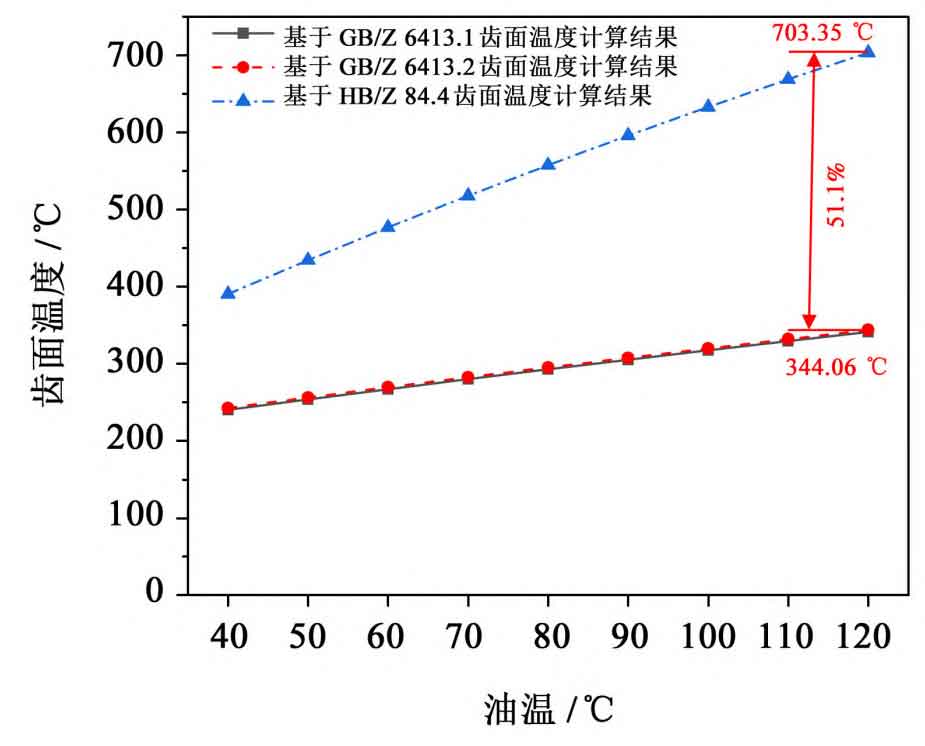

The oil temperature affects the viscosity of the lubricating oil, and then the friction coefficient between the tooth surfaces, resulting in the change of the calculation results of the tooth surface temperature. Select the torque under FZG test load level 12 and calculate the tooth surface temperature under different oil temperatures. The oil temperature changes between 40 and 120 ℃, and the increase gradient of each group of oil temperature is 10 ℃. The tooth surface temperature, average flash temperature and tooth surface temperature under the three standard calculation methods are calculated respectively. The calculated results of three standard tooth surface temperatures at different oil temperatures are plotted in Figure 3. It can be found that HB/Z 84 The calculated result of tooth surface temperature of 4 is significantly higher than that of GB/Z 6413 1 and GB/Z 6413 2. The difference of calculation results increases with the increase of oil temperature. At 120 ℃, HB/Z 84 The tooth surface temperature calculation result of 4 is the same as that of GB/Z 6413 The maximum difference of 2 is 51 1%。 At different oil temperatures, GB/Z 6413 1 and GB/Z 6413 2. The error of tooth surface temperature calculation result shall not exceed 5%.

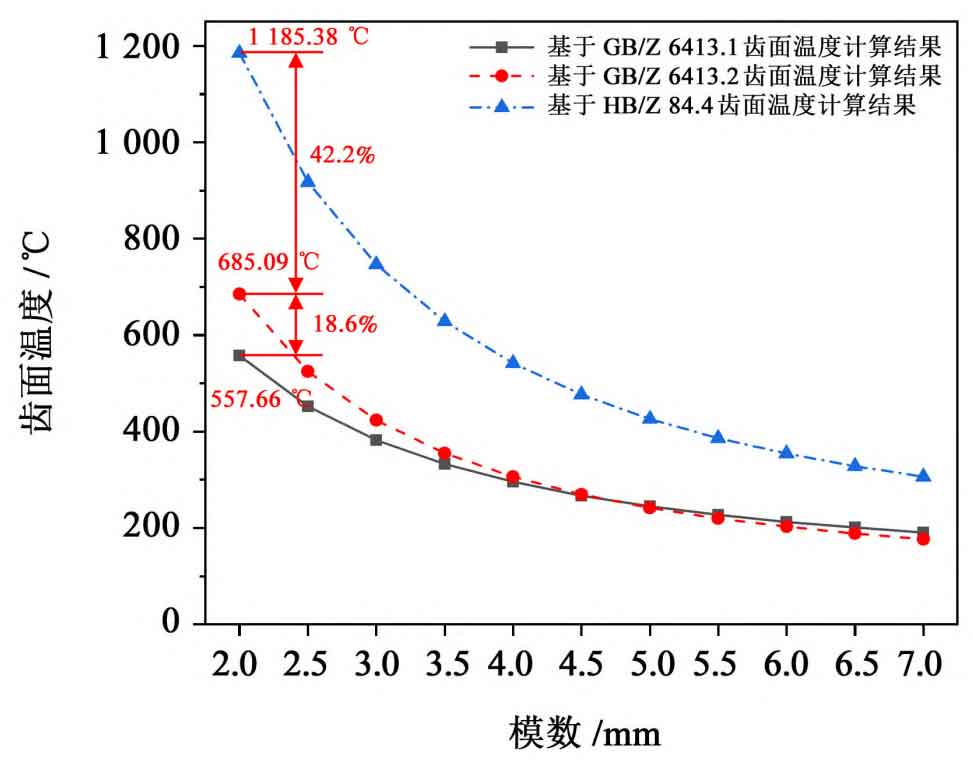

The structure, size and geometric parameters represented by modulus also have influence on the thermal behavior of involute cylindrical gears. The comparison of tooth surface temperature calculation results under different modulus (2~7 mm) was carried out under FZG test load level 12. Calculate the body temperature, average flash temperature and tooth surface temperature under three standard calculation methods for different modules. The calculated results of tooth surface temperature based on three criteria are plotted in Figure 4. It can be found that HB/Z 84 The calculated result of tooth surface temperature of 4 is significantly higher than that of GB/Z 6413 1 and GB/Z 6413 2, and the difference of calculation results increases with the decrease of modulus. When the modulus is 2 mm, HB/Z 84 The tooth surface temperature calculation result of 4 is the same as that of GB/Z 6413 The maximum difference of 2 is 42 2%, resulting in HB/Z84 4. The temperature of the middle gear surface is higher than GB/Z 6413 2。 The modulus is within 2~4 mm, GB/Z 6413 2. The tooth surface temperature is higher than GB/Z 6413 1; When the modulus is 2 mm, the difference between the two is 18 6%; When the modulus is within 4~7 mm, there is little difference between the calculated results of the tooth surface temperature of the two. The reason for this phenomenon is that when the modulus is too small, the lubricant coefficient XL and roughness coefficient XR of the two are different, so the average friction coefficient is different, resulting in the difference in tooth surface temperature.

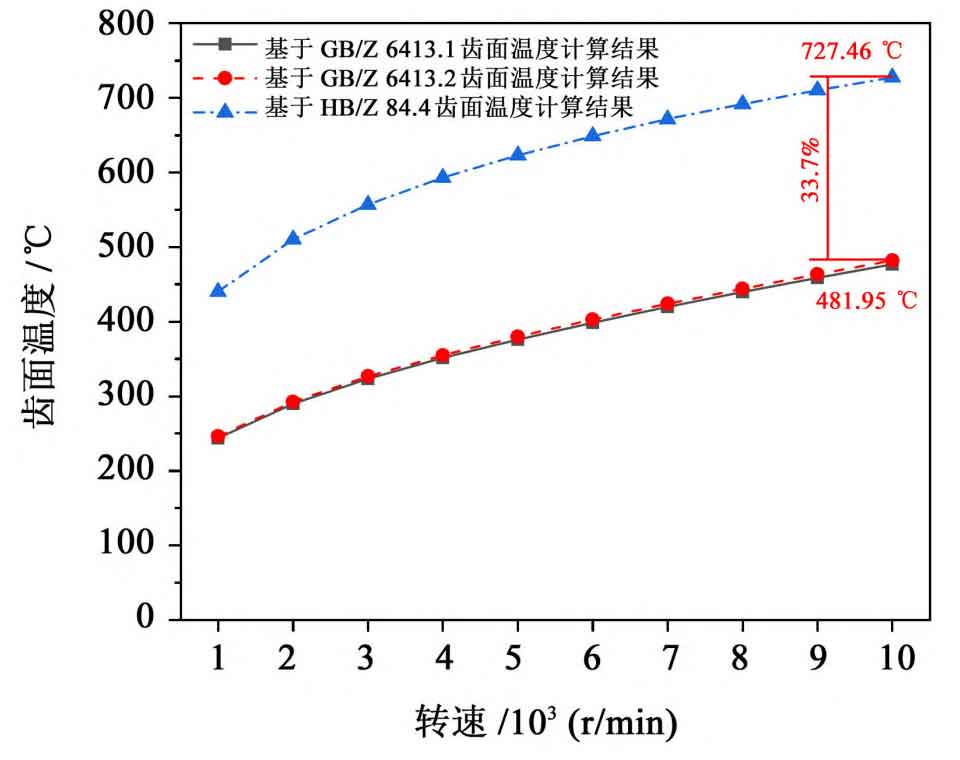

The speed of involute cylindrical gear determines the relative tangential sliding speed between two meshing tooth surfaces. The relative tangential sliding speed affects the tooth surface temperature by affecting the formation of oil film. The calculation results of tooth surface temperature at different rotational speeds are compared under the FZG test load level 12. The rotating speed varies from 1000 to 10000 r/min, and the increase gradient of each group of rotating speed is 1000 r/min. The body temperature, average flash temperature and tooth surface temperature under three standard calculation methods with different rotating speeds are calculated respectively. The calculation results of the three standard tooth surface temperatures are shown in Figure 5. It can be found that HB/Z 84 4. The calculated result of tooth surface temperature is significantly higher than that of GB/Z 6413 1 and GB/Z 6413 2, and the difference of calculation results increases with the increase of speed. At 10 000 r/min, HB/Z84 4. Tooth surface temperature ratio GB/Z 6413 2 High 33.7%. GB/Z 6413 1 and GB/Z 6413 2. The error of tooth surface temperature calculation result shall not exceed 5%.