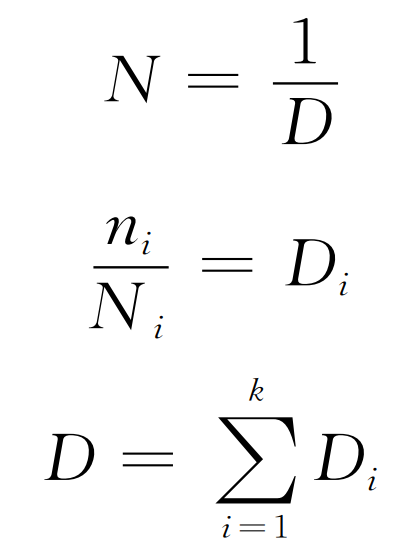

According to the linear fatigue cumulative damage theory Miner theory, the stress amplitude of each stress level will cause certain damage to the spur gear. In this paper, the fatigue damage value Di is obtained by dividing the actual cycle number Ni by the fatigue life cycle number Ni. The contact fatigue cumulative damage value of the spur gear is equal to the sum of the damage caused by all stress levels. Finally, the critical value 1 is divided by D to obtain the fatigue life n, The specific calculation method is as follows.

Where: Ni is the number of fatigue life cycles, and Ni is the number of actual stress cycles; N is the fatigue life of spur gears.

| Parameter / unit | Numerical value |

| Parameter mass m / kg | 1530 |

| Windward area A | 2.4 |

| Wheel rolling radius r / m | 0.314 |

| Mechanical efficiency of drive train η | 0.95 |

| Air damping coefficient CD | 0.261 |

| Total transmission ratio of reducer i | 6.72 |

| Rolling resistance coefficient f | 0.015 |

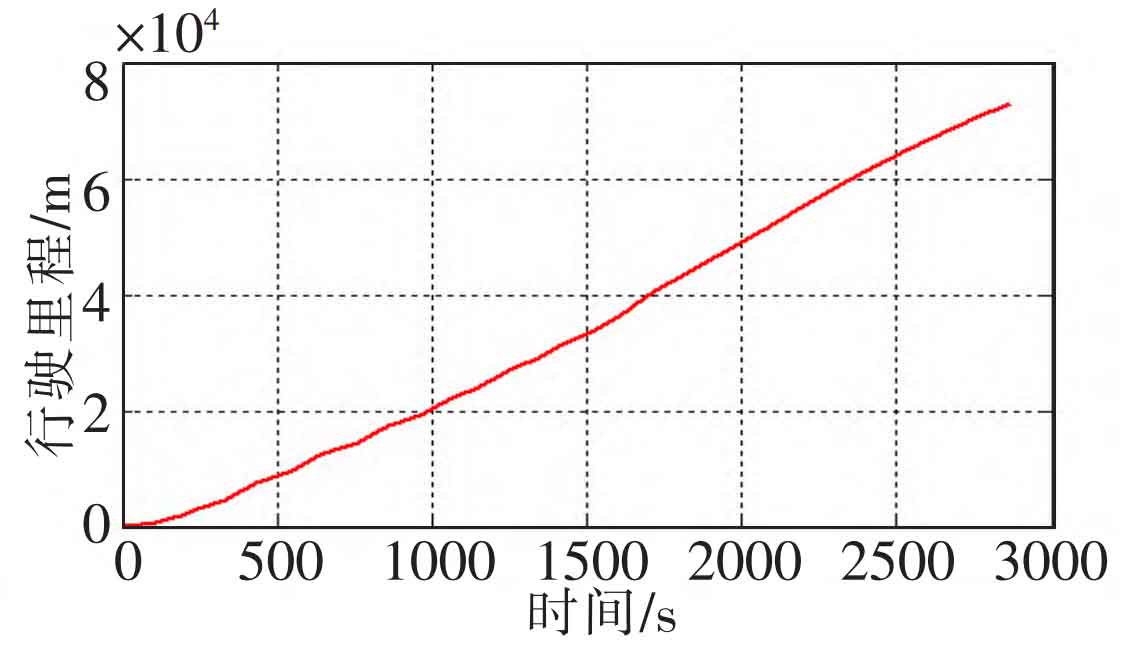

D1, D2, D3,… Di can be obtained according to the modified gear S-N logarithmic curve, the converted contact stress amplitude frequency relationship of spur gears, and formula (5), so that the contact damage of spur gears based on the measured load spectrum is d = 2 029 × 10-4, and then divide the critical value 1 by D to obtain the contact fatigue life of spur gears based on the measured load spectrum n = 4928. The mileage of running a load spectrum is: motor speed / transmission ratio / 60 * π * tire diameter and integration (the parameters of the whole electric vehicle studied are shown in the table). The results are shown in Figure.

The calculated load mileage for one load is 72.86km, so the service life mileage of electric vehicle reducer gear based on the measured load spectrum is 4928 * 72.86km = 359100 km.