From the previous analysis, as long as the elastic deformation of the gear teeth is obtained, the time-varying meshing stiffness can be determined. Therefore, we first discuss the calculation method of comprehensive elastic deformation of spur gear teeth. Spur gear teeth can generally be treated as simple plane mechanical problems. The calculation methods of elastic deformation under load mainly include: material mechanics calculation method, elastic mechanics calculation method and numerical calculation method represented by finite element method.

Mechanics of materials is the earliest and widely used method to calculate the elastic deformation of gear teeth. It is of practical significance to study the modification of spur gear and load distribution between teeth. As early as 1929, R.V. band and R.E. Peterson proposed using variable cross-section cantilever beam to simulate gear teeth to calculate their elastic deformation. From 1938 to 1940, when studying tooth profile modification, H. Walker combined test and theory to determine the tooth deformation. In 1949, based on the study of H. walker, C. Weber first decomposed the tooth deformation into shear deformation, bending deformation and compression deformation. The calculated results are basically consistent with the test results of H. walker. Later, J. Ishikawa also gave a similar calculation method. In 1964, A.Y. attia introduced the rim deformation into the calculation of tooth elastic deformation. In 1973, T. tobe et al. Discussed the influence of tooth skew. In 1980, R.W. Cornell published his research summary on the deformation of spur gear teeth. In the summary, he considered the bending deformation, shear deformation, contact deformation, the geometry of tooth root fillet and the elastic deformation of tooth support foundation. In the study of K. nagaga et al. In 1981, the moving speed of the load acting on the tooth surface of the gear tooth was taken into account in the calculation and analysis of gear tooth deformation.

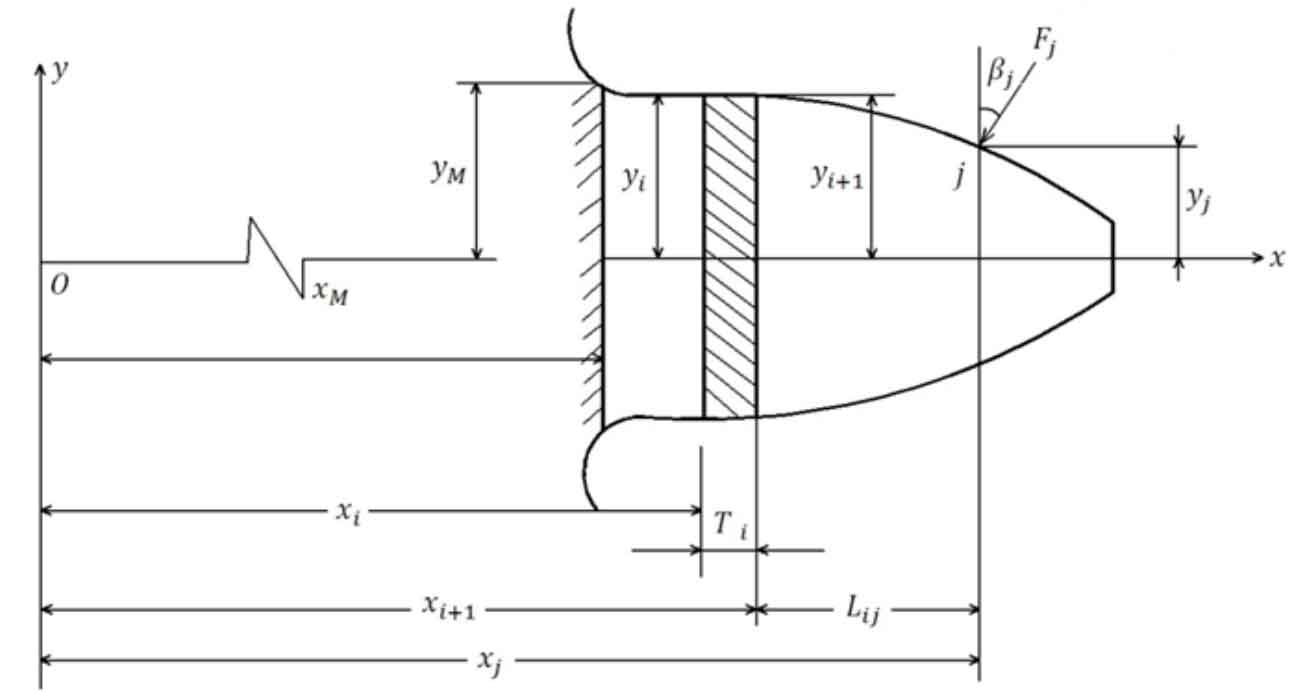

Taking the spur gear shown in the figure as an example, in order to calculate the positive pressure acting on the point on the gear surface and the comprehensive elastic deformation of the gear tooth under the action of the point, the calculation method of material mechanics is to simplify the gear tooth of the spur gear into a variable cross-section cantilever beam with one end fixed on the elastic foundation. It is considered that the deformation of the gear tooth is caused by the shear deformation of the variable cross-section cantilever beam It is composed of bending deformation and elastic deformation of supporting foundation. The calculation methods of various deformations are discussed below.