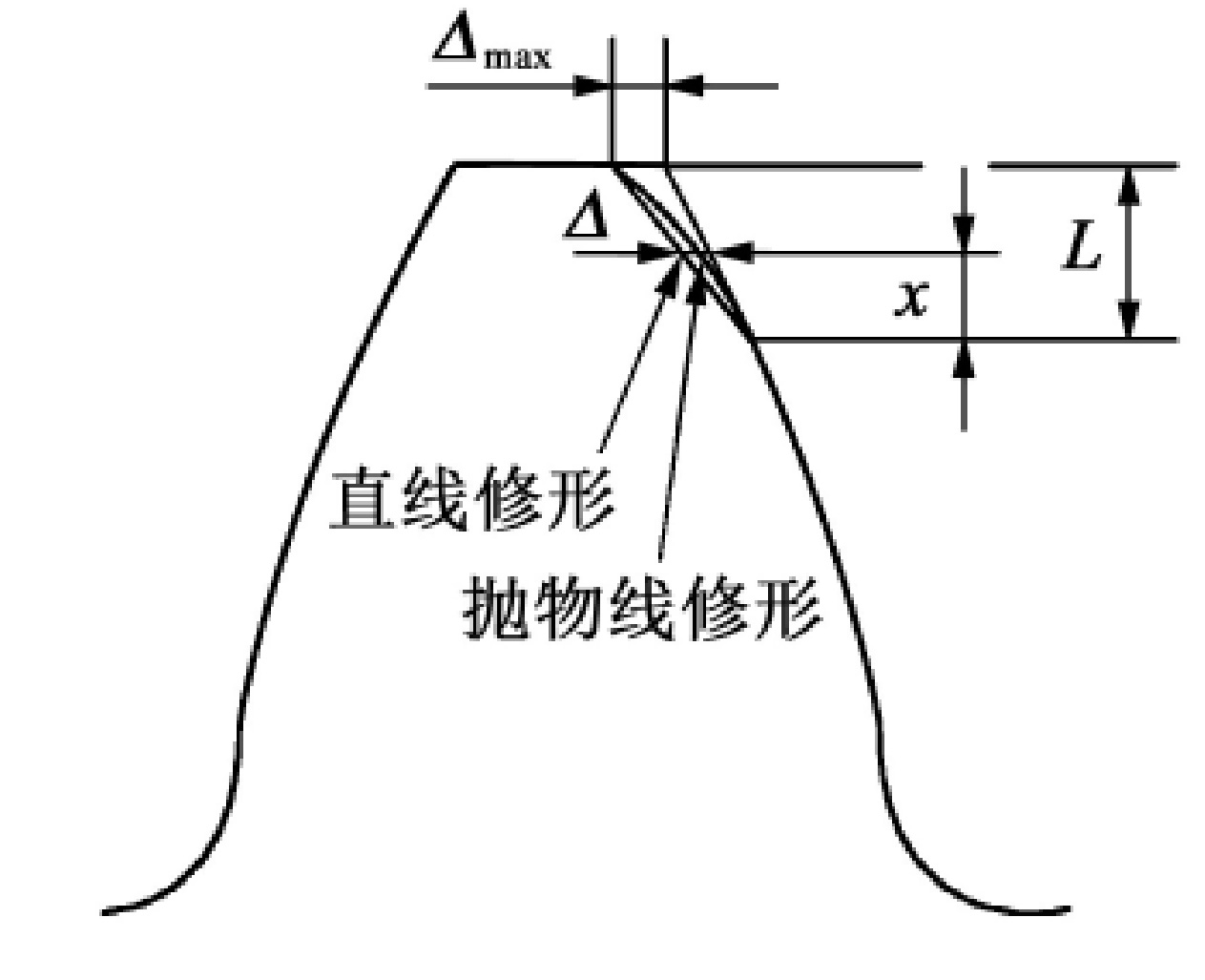

Three elements of spur gear modification: maximum modification amount of tooth profile Δ Max, straight tooth profile modification length L, and tooth profile modification curve, as shown in the figure.

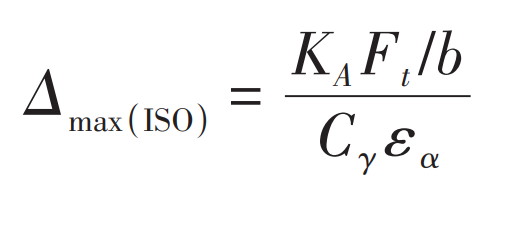

ISO maximum modification amount Δ The recommended formula for max (ISO) is:

In the formula, KA is the operating condition coefficient; Ft/b is the circumferential force per unit tooth width, N/mm; C γ Is the spur gear meshing stiffness, N/(mm · µ m); εα Is the gear end face overlap.

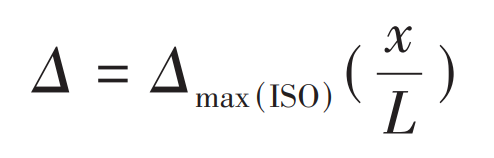

The spur gear modification curve is used to calculate the amount of modification in the modification area and describe the modification profile of the spur gear. Among them, the most commonly used modification curve is linear modification. The equation for the tooth profile modification curve is:

In the equation, Δ The modification amount of the spur gear modification curve at x, µ m; X is the relative coordinate of spur gear contact point, and 0 ≤ x ≤ L.

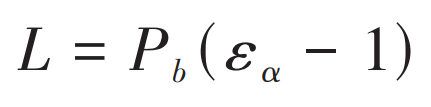

The length L of straight tooth profile modification can be divided into long modification and short modification. Generally, the modification curve of long modification is smoother. According to the method of Junfu Huida, the calculation formula for the long form correction is:

In the formula, Pb is the base pitch of the gear end face, mm; εα Is the gear end face overlap.