The calculation of rotary forging deformation force can provide a theoretical basis for selecting the tonnage of rotary forging machine. Because the cold rotary forging of bevel gear is asymmetric and uneven deformation under local loading, the whole deformation process is an unsteady problem, and the shapes of cone die and female die are complex, so it is inconvenient to analyze and calculate. Therefore, it is more appropriate to use “energy method” to analyze the deformation force required in the forming process.

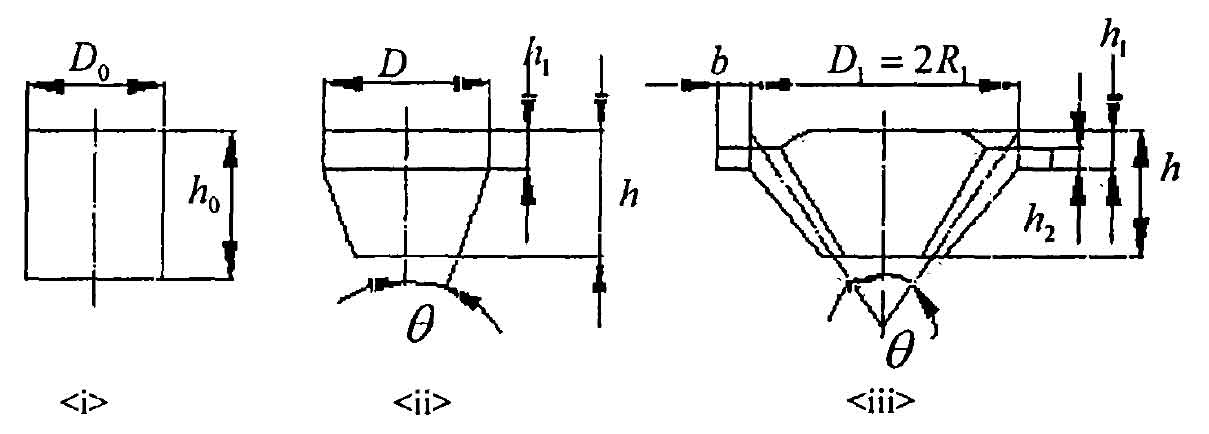

The “energy method” is used to study the plastic deformation force of bevel gear cold rotary forging, and the process of bevel gear cold rotary forging is simplified: as shown in Figure 1, the cylindrical blank is rotary rolled into conical platform shape, and then the tooth shape part is formed, and flash occurs, in which the workpiece height remains unchanged in < II >, < III > two stages.

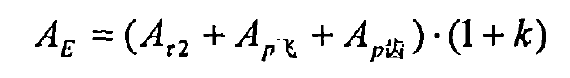

And the following conclusions are obtained: in the process of bevel gear cold swing rolling, the work done by the external force along the displacement direction is equal to the sum of the work done by the internal force (i.e. plastic deformation work) and the work done to overcome the friction resistance. Among them, the plastic deformation work includes: the plastic work consumed by the deformation area when the cylinder blank is rotary rolled into a cone table, the work consumed by the displacement discontinuity and the work consumed by the formation of flash and tooth shape; Friction resistance work includes: friction work between workpiece (excluding flash) and swing head and female die, and friction work between flash and swing head and female die. However, among the above parts of energy, the work consumed by the shear force of the pier extrusion section, the work consumed by the friction between the flash and the swing head and the contact surface of the female die, and the plastic deformation energy of the tooth shape part account for the main part of the total energy. Therefore, the total energy consumed in the cold swing rolling process of the bevel gear can be simplified to the following expression:

Of which:

(1) AE is the total energy consumed in the cold rotary forging process of bevel gear;

(2) K = 0.2-0.25. K is the coefficient of material hardness. The greater the hardness of the material, the smaller the K value;

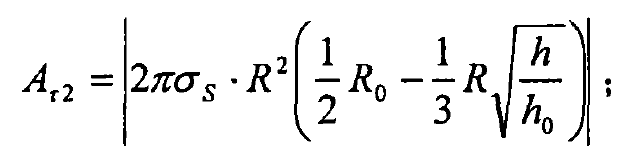

(3) AV2 is the work consumed by the shear force of the pier extrusion interface, and

Where,

σ S – yield stress of bevel gear material;

R – the radius of the dividing circle at the big end of the bevel gear, and R = m · Z / 2 (m, Z are the modulus and number of teeth of the bevel gear respectively);

H – thickness of bevel gear;

R0 – radius of preform;

H0 – height of preform.

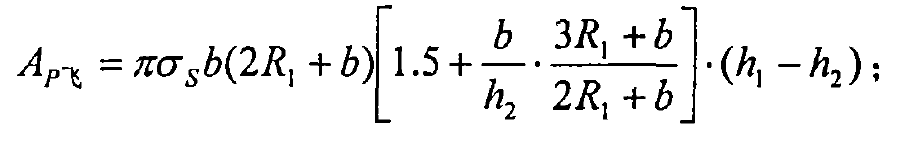

(4) AF is the work consumed by the friction between the flash and the contact surface of the swing head and female die, and:

Where,

R1 – radius of inner circle of flash;

B – Flash width;

H1 – height of workpiece above conical table;

H2 – Flash thickness.

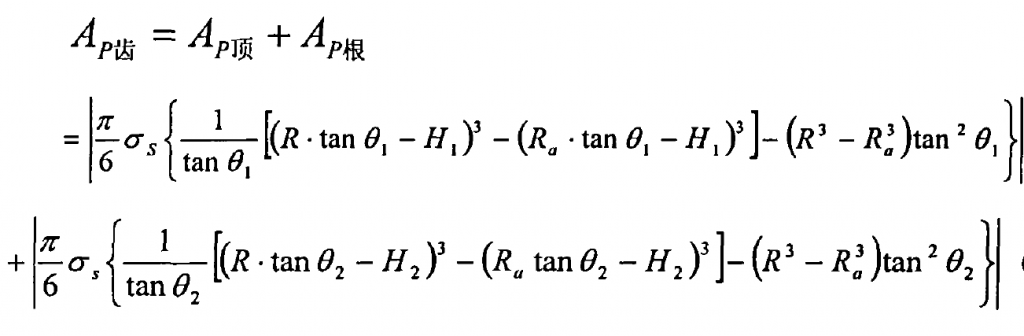

(5) AP tooth is the plastic deformation energy of tooth profile part, which includes the plastic deformation energy of tooth top part and tooth root part, and

Where,

R α— Index circle radius of bevel gear small end, and R α= R-(h-h1)·tan θ ( θ Umbrella teeth

Indexing wheel (cone angle)

θ 1, θ 2 – bevel gear tip cone angle and tooth root cone angle respectively;

H1, H2 – tooth top height and tooth root circle of bevel gear respectively.

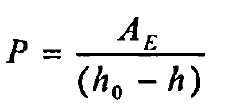

Let the rotary forging deformation force be p, which is obtained from the conservation of energy. The calculation formula of rotary forging force is:

The rotary forging force can be calculated by substituting the formula into the above formula.