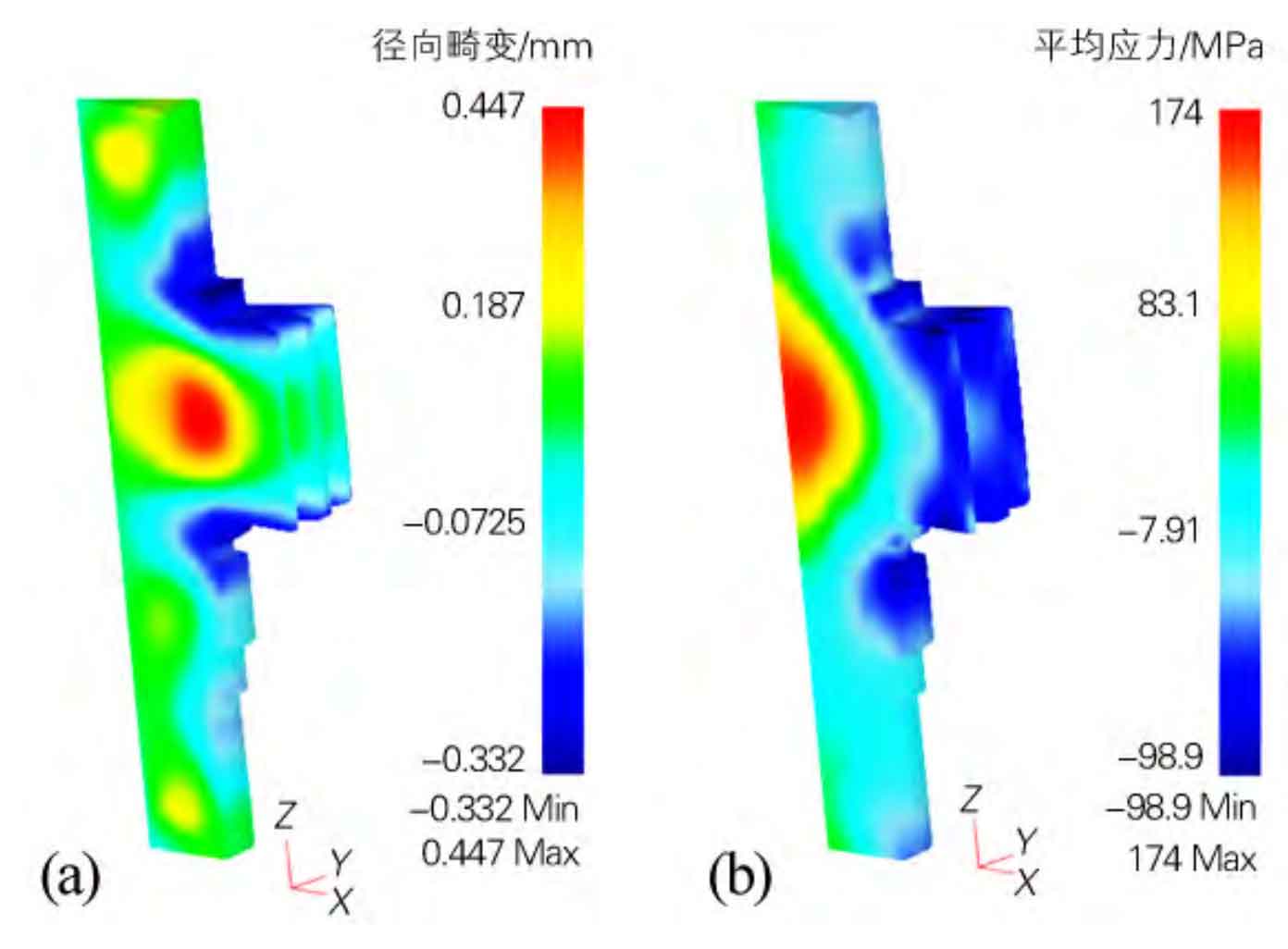

In production, the preheating temperature and time parameters of gear shaft are more based on the experience of workers. Based on practical experience, several groups of preheating process parameters of gear shaft are determined, as shown in the table. The radial distortion of each process is shown in Figure 1. It can be seen that the distortion of group 5 is the smallest. Therefore, it can be determined that the optimal preheating temperature of the gear shaft is 400 ℃ and the preheating time is 3 h.

| Process number | Preheating temperature / ℃ | Preheating time / h |

| 1 | 350 | 2 |

| 2 | 400 | 2 |

| 3 | 450 | 2 |

| 4 | 350 | 3 |

| 5 | 400 | 3 |

| 6 | 450 | 3 |

| 7 | 350 | 4 |

| 8 | 400 | 4 |

| 9 | 450 | 4 |

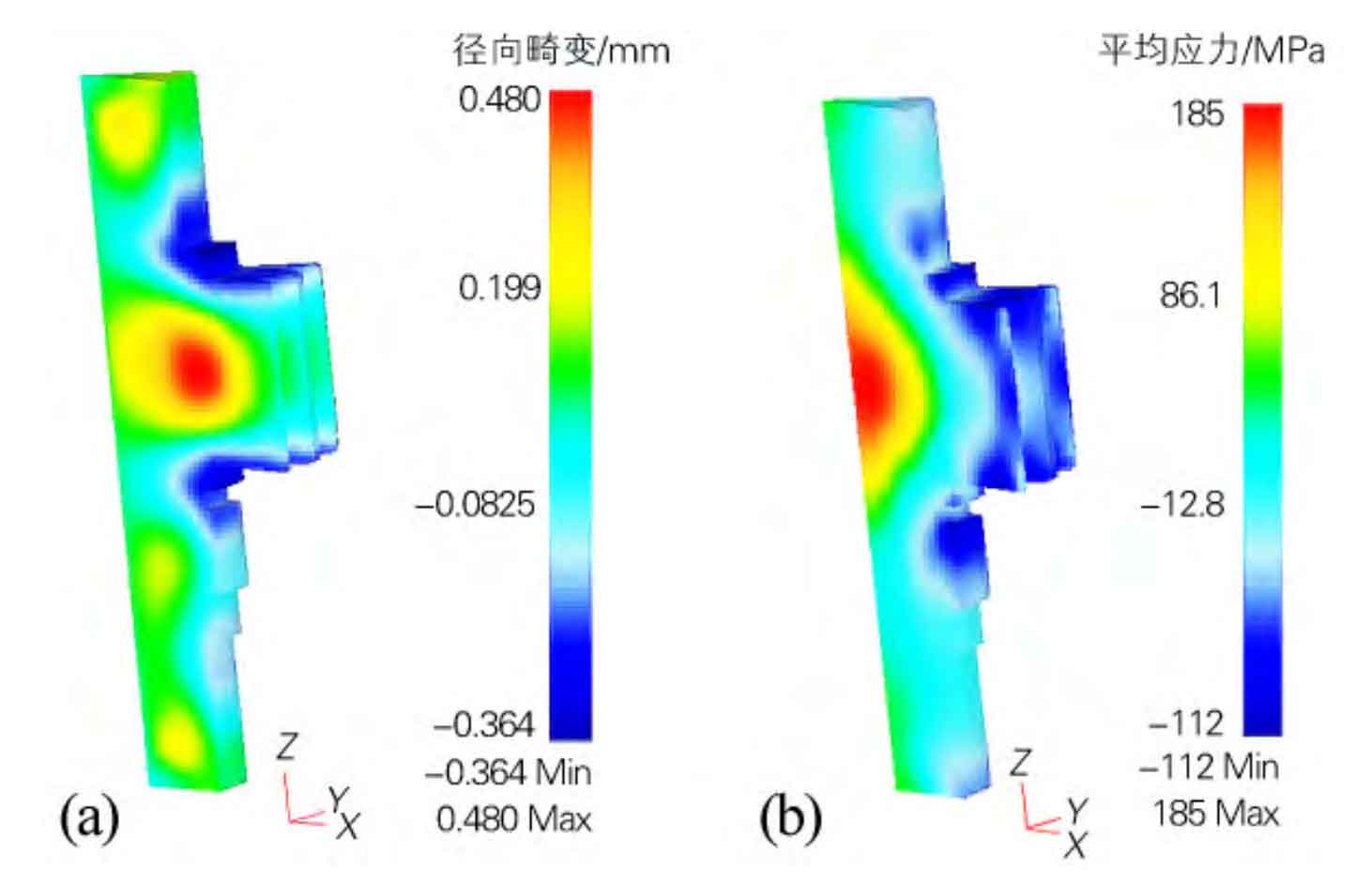

After carburizing and quenching based on the best preheating treatment, the radial distortion and average stress distribution are shown in Figure 2. It can be seen from Fig. 2 that the radial distortion and residual stress of the gear shaft after carburizing and quenching after gear shaft preheating treatment are reduced compared with Fig. 3.