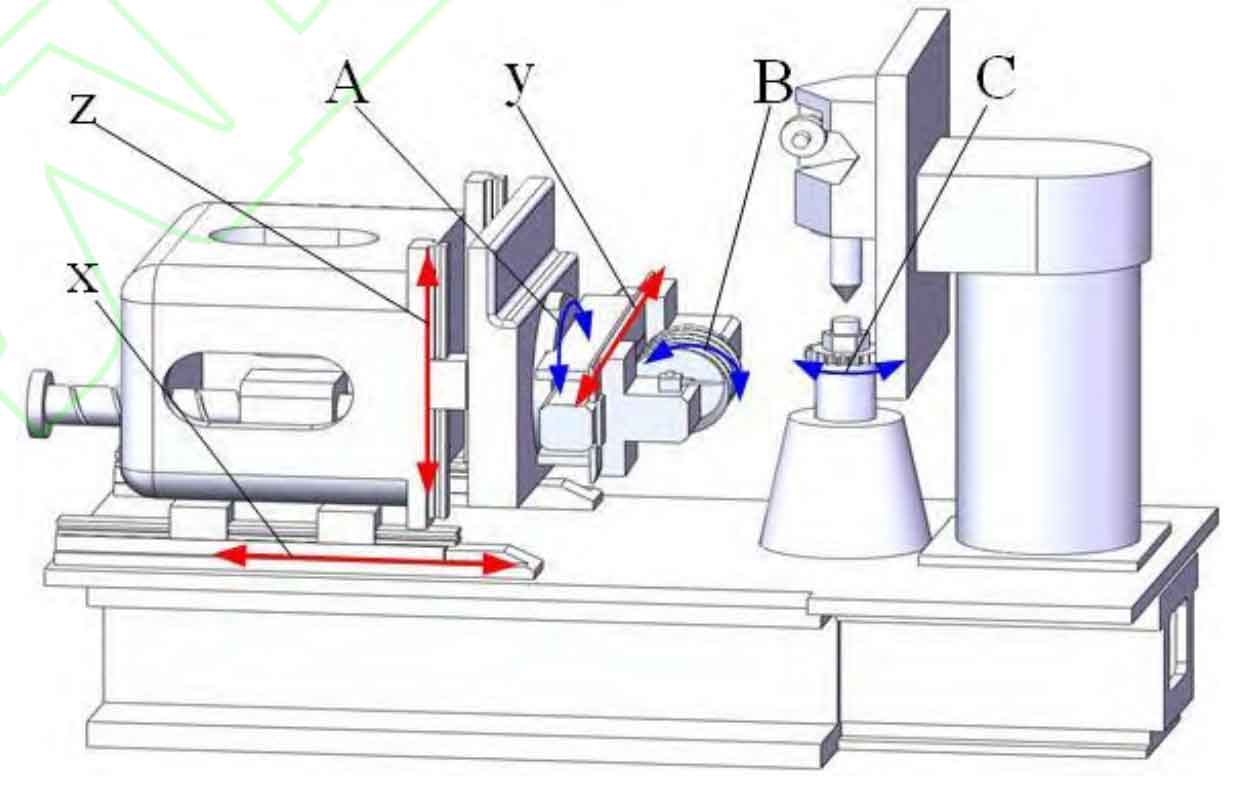

Different from the traditional chamfering method of tooth profile, the new method of continuous cutting chamfering with cutting tools is studied. Combined with the hobbing movement of cylindrical gear (shown in Figure 1) and the chamfering requirements of end tooth profile, the tool is designed as a single multi head hobbing chamfering tool, and the number of teeth of the tool is the number of heads of the hob. The cutter (rotating with axis B) and the cylindrical gear (rotating with axis C) are chamfered through continuous hobbing movement, and the chamfering of the end face profile of the cylindrical gear is completed by using the edge shape of the rake face of the cutter. Different from the principle of gear hobbing generating envelope on the tooth surface, the chamfering tool profile and the chamfering target profile of cylindrical gear are in point contact at every instant, and the two profiles are no longer conjugate profiles. With the continuous hobbing movement of the tool and cylindrical gear, the contact points of the left and right tooth profiles are asymmetrically arranged.

In order to avoid scratching the tooth surface, use the X, y and Z axes in Figure 1 to adjust the installation position of the tool, and use the a axis to adjust the installation attitude of the tool. During machining, the cutter rotates continuously and the cylindrical gear is indexed continuously, which has the advantages of continuous machining process, high precision and efficiency.

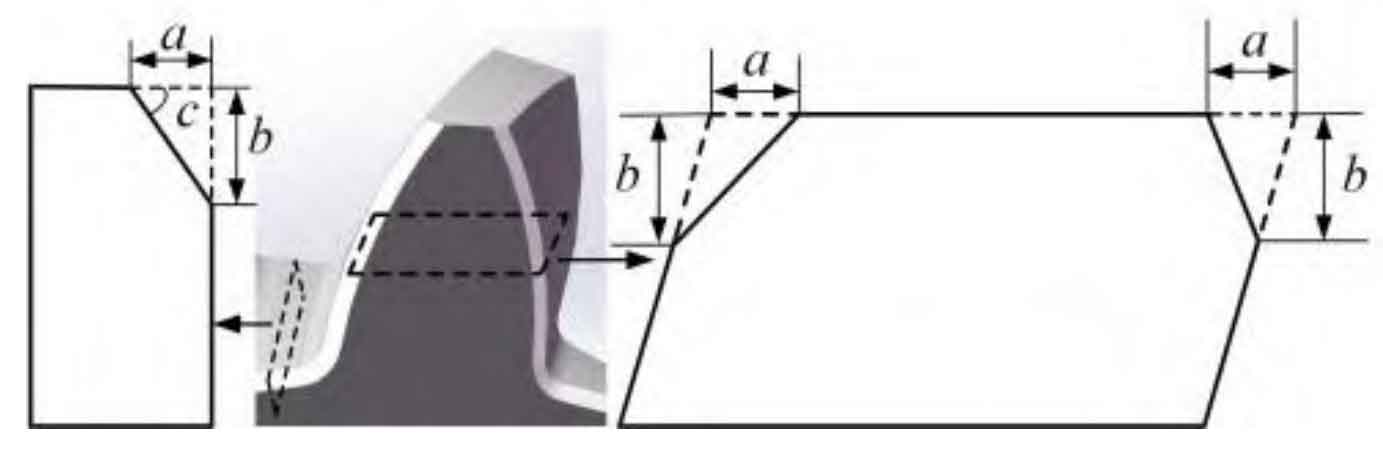

The evaluation of chamfering effect is mainly measured by chamfering parameters (chamfering thickness a, chamfering width B and chamfering angle c) (as shown in Figure 2). Chamfering parameters are closely related to the parameters of cylindrical gear and the installation parameters of cutting tools. For cylindrical spur gears, the chamfering angle of the whole tooth profile is the same; The cylindrical helical gear is different. Therefore, the chamfering angle is measured only at the root circle. A series of position points are symmetrically selected on the left and right end tooth profiles of the chamfered cylindrical gear as the chamfering effect evaluation points. By comparing the chamfering parameters of the chamfering effect evaluation points, the symmetry of the chamfering effect evaluation points of the left and right tooth profiles and the consistency of the chamfering effect evaluation points of the whole tooth profile are studied, and the effect of hobbing chamfering is analyzed.