In the meshing transmission of cylindrical gear mechanism, there is a large tangential relative sliding speed along the tooth length direction, so it will produce large wear; On the other hand, the tooth profiles of the two wheels are in point contact, and the contact stress will be very large As a result, the Q surface is pressed and fed prematurely, which aggravates the wear of gear teeth. Compared with parallel shaft helical gear, the service life and mechanical efficiency of staggered shaft helical gear mechanism are much lower.

Because the staggered shaft helical cylindrical gear mechanism has the above characteristics, it is not suitable for transmitting power, that is, it is not suitable for high-speed and heavy load environment. Generally, it is only suitable for transmitting motion or changing the direction of motion. The helical angle and direction of the two gears of the staggered shaft helical gear mechanism are not necessarily the same, so the center distance, angular speed ratio and relative steering of the two wheels can be adjusted by changing the helical angle A. and intestine. The mechanism is easy to meet the geometric requirements of staggered transmission between gears.

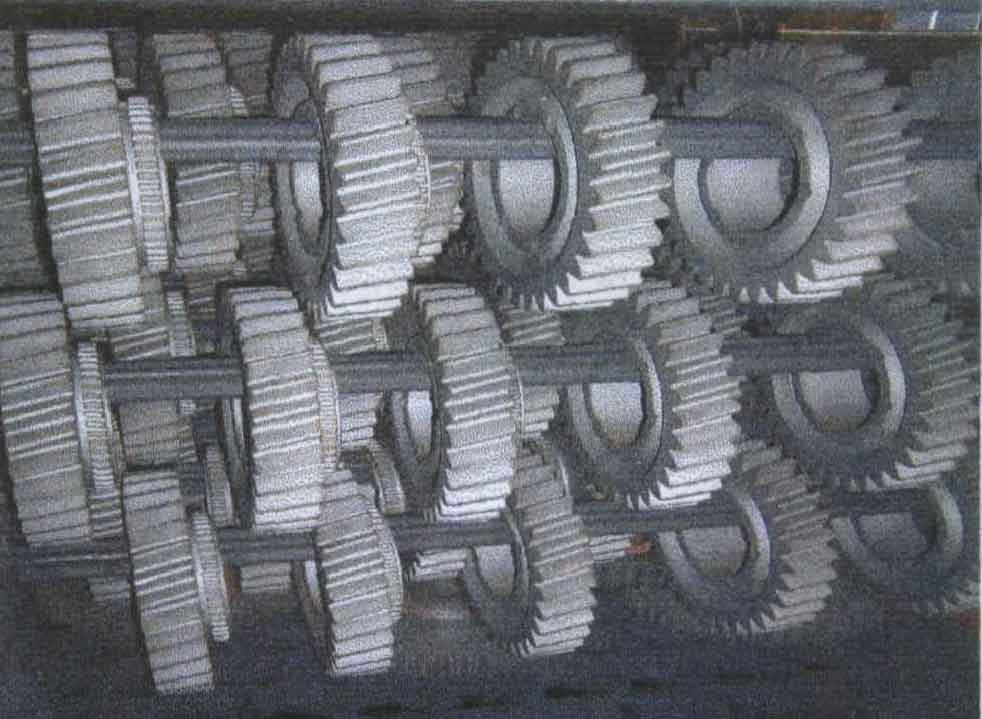

The most basic types of cylindrical gears are cylindrical spur gear mechanism and cylindrical helical gear mechanism, which transmit the motion between parallel shafts. Gear can be divided into cycloid gear and involute gear according to the most different profile.