The time-varying transmission error te (transmission error) and mesh stiffness change are the main excitation sources in the dynamic meshing process of hypoid gears of the drive axle. In the past, many scholars have conducted in-depth research on the methods of establishing mathematical or numerical models to simulate the dynamic behavior of the drive axle hypoid gear system, including the single degree of freedom lumped parameter model to the finite element model. The transmission error and meshing stiffness of hypoid gears in the single degree of freedom model are generally obtained by simple assumptions or simplified finite element calculation results.

The load tool contact analysis LTCA (load tool contact analysis) based on the finite element method can truly reflect the working state of the hypoid gear due to the elastic deformation of the gear blank. Therefore, by using this method to analyze the load transmission error of the hypoid gear, the actual transmission error (TE) of the hypoid gear can be obtained. The load transmission error can be obtained through LTCA analysis, but the factors affecting the transmission error of hypoid gears, such as the input load conditions and the influence of the installation deviation of hypoid gears, have not been studied in detail. In terms of meshing stiffness calculation of hypoid gears, foreign scholars have proposed the corresponding calculation process for calculating the time-varying meshing stiffness of hypoid gears based on the transmission error angle of hypoid gears, but the specific calculation details have not been disclosed. There are few studies on calculating the meshing stiffness of hypoid gears by using ABAQUS or ANSYS software, which is widely used at present, and there are still shortcomings in establishing an accurate meshing stiffness calculation model of hypoid gears.

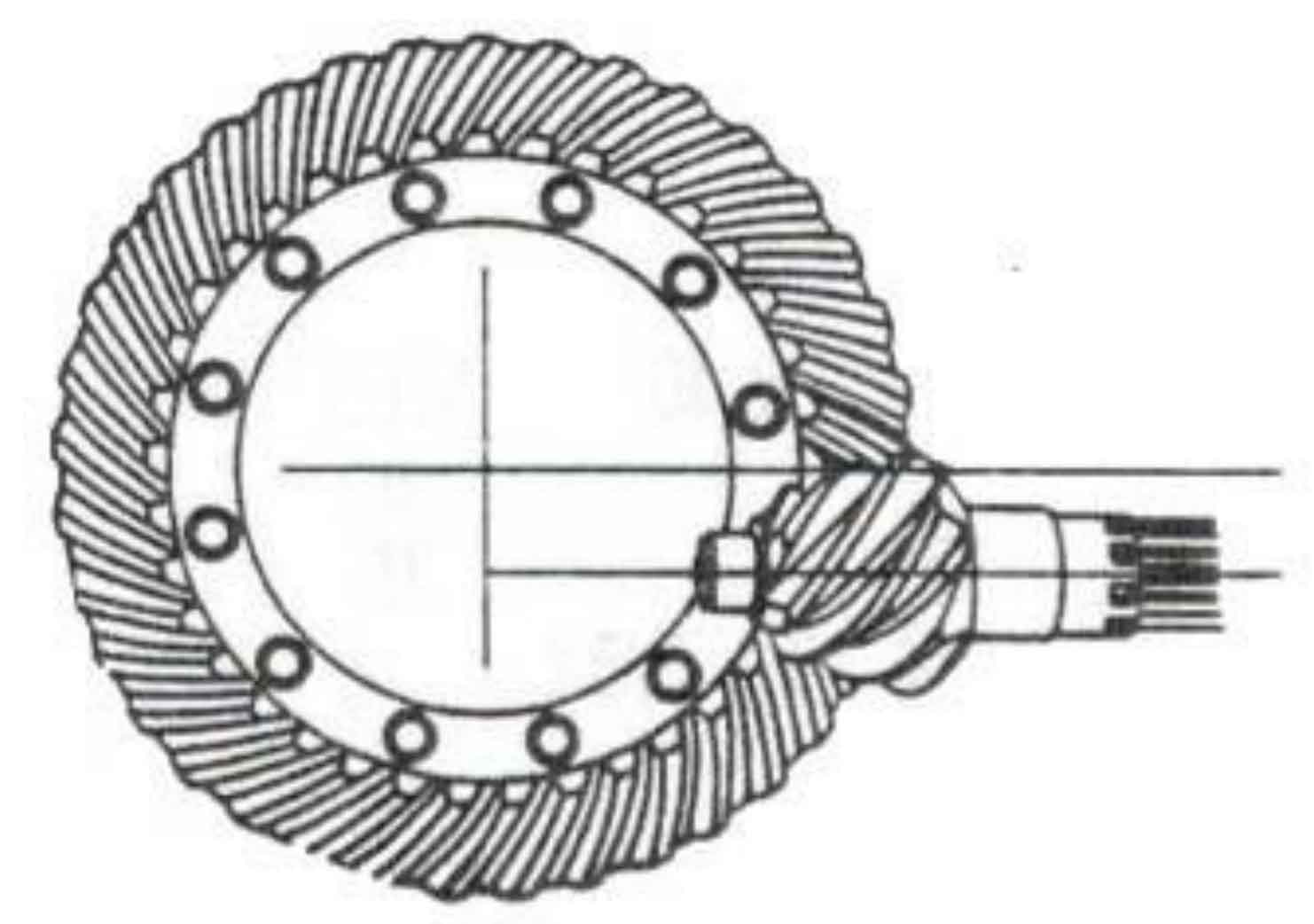

Therefore, the time-varying transmission error and meshing stiffness of hypoid gears are studied based on the finite element method. Firstly, the finite element meshing model of the hypoid gear of the drive axle is established, and the dynamic and static transmission errors of the hypoid gear under load are obtained. Secondly, the influence of installation deviation and load on transmission error is analyzed. Thirdly, the relationship between static and dynamic transmission errors and the influence of speed fluctuation on transmission errors are analyzed. Finally, a method for calculating meshing stiffness of hypoid gears based on transmission error is established. This meshing stiffness provides the basis for establishing the dynamic model of hypoid gear of drive axle.