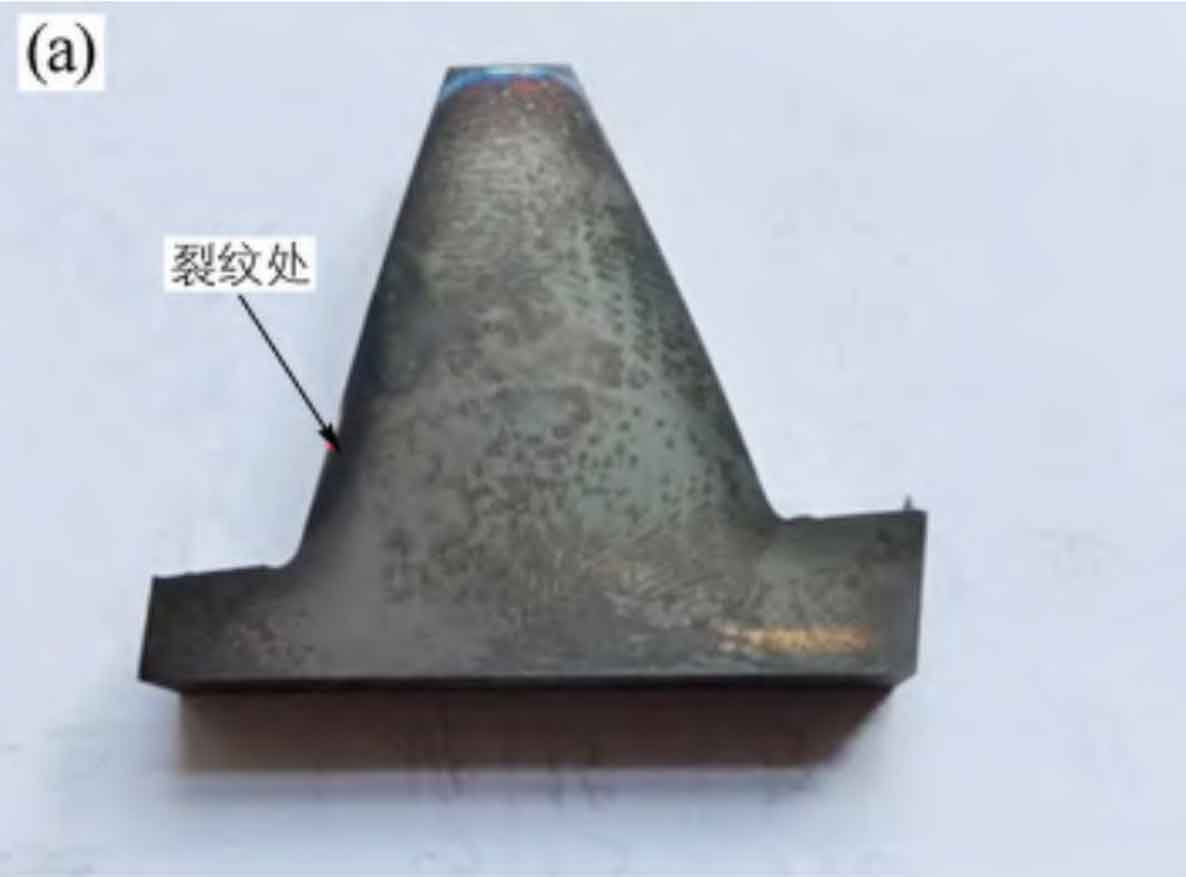

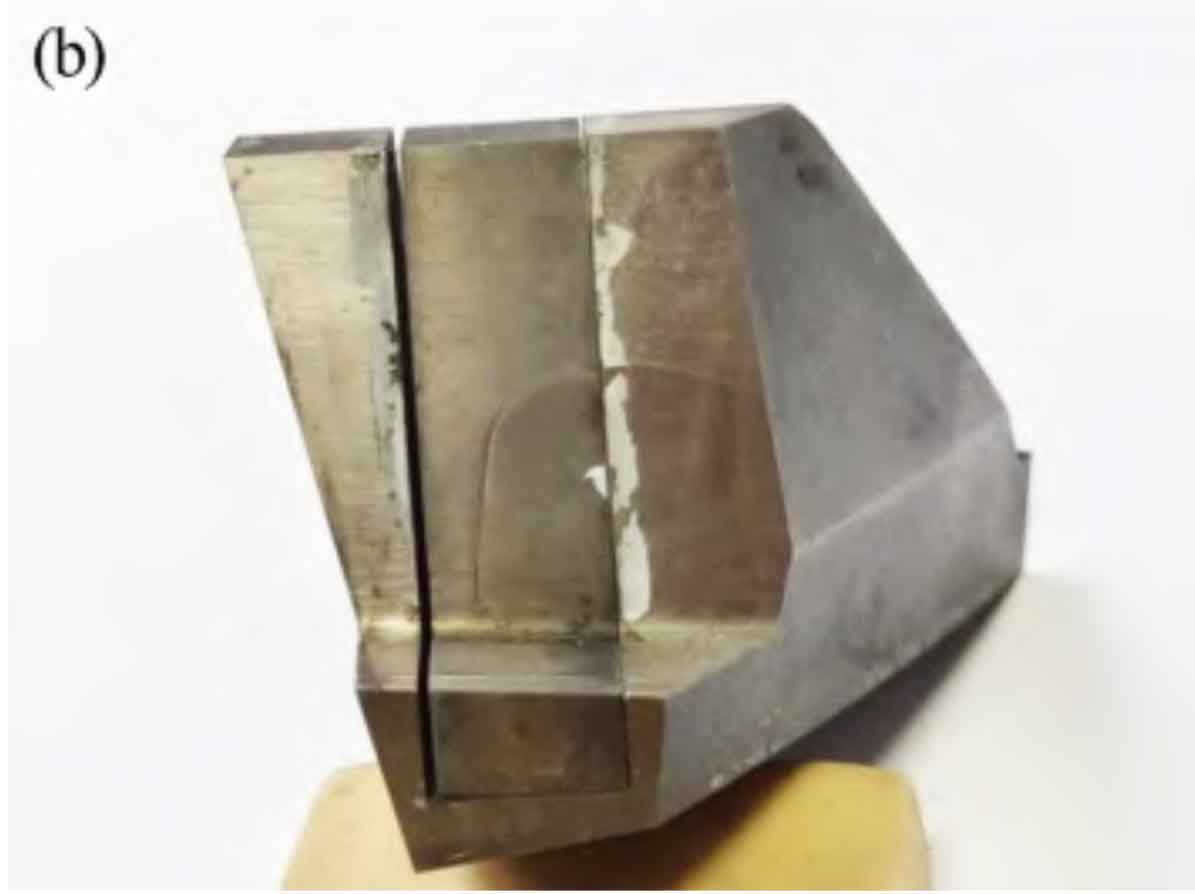

The tooth top hardness of cracked spiral bevel gear is 61~62 HRC, which meets the technical requirements of 58~62 HRC drawing. Take samples at the large end of cracked spiral bevel gear, and the shape of the cut tooth block is shown in Figure (a). The left side is the crack surface, which is the convex surface of the bevel gear, the right side is the non-crack surface, which is the concave surface of the bevel gear, and the convex surface, which is the crack morphology on the crack surface, is shown in Figure (b). The crack on the tooth surface is circular arc, There is a sense of warping at the crack.

Take samples from the non-carburized part of the tooth block center near the spoke to test the chemical composition of the bevel gear. The results are shown in the table. It can be seen from the table that the content of carbon and nickel in the center of cracked spiral bevel gears is higher than the upper limit of GB/T 3077-2015 Alloy Structural Steel.

| Element | C | Si | Mn | P | S | Cr | Ni |

| Measured | 0. 249 | 0. 291 | 0. 554 | 0. 016 | 0. 011 | 1. 652 | 4. 149 |

| GB/T 3077— 2015 | 0. 17 ~ 0. 23 | 0. 17 ~ 0. 37 | 0. 30 ~ 0. 60 | ≤ 0. 030 | ≤ 0. 030 | 1. 25 ~ 1. 65 | 3. 25 ~ 3. 65 |