In the meshing process of double-arc spiral bevel gear pair, the process of single pair of teeth from entering meshing to exiting meshing is defined as a meshing cycle. One meshing period of a single pair of teeth Δ T and the time difference between the two adjacent teeth entering the mesh Δ The ratio between t is the coincidence degree of double-arc spiral bevel gear. Under quasi-static conditions, the coincidence degree can be defined as:

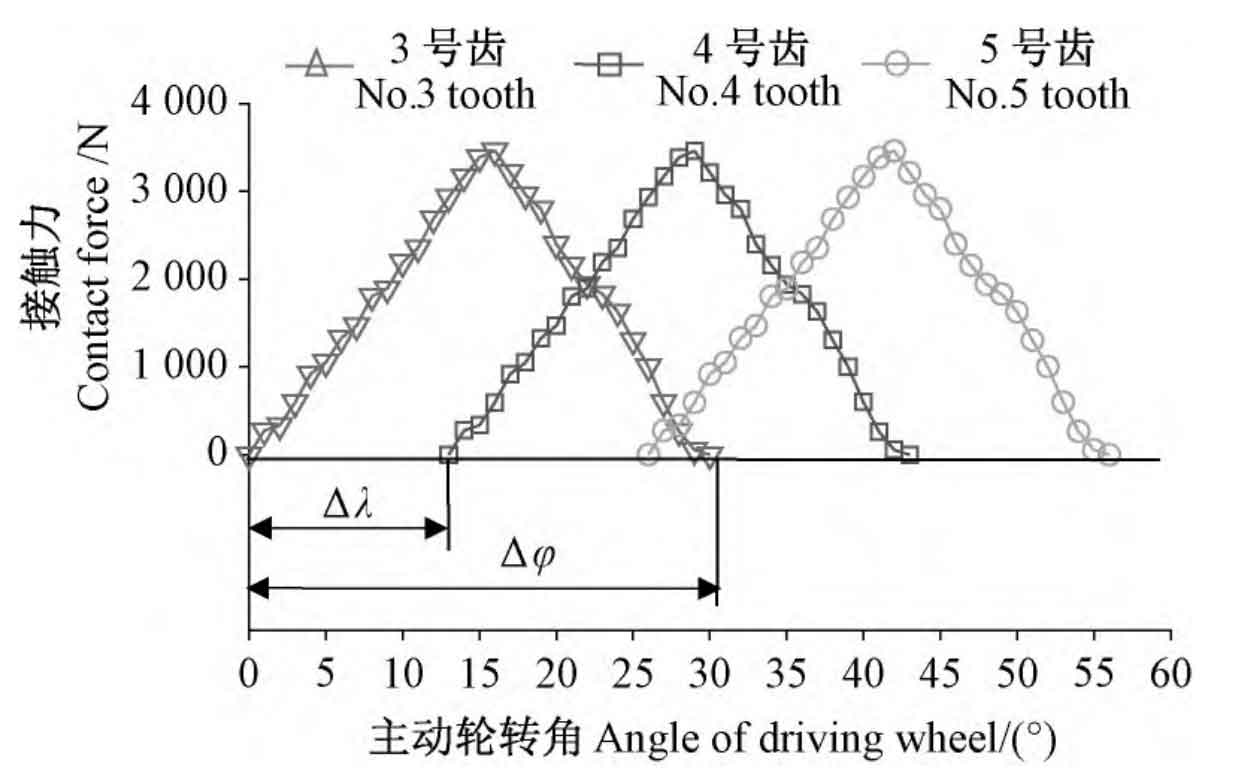

Where, Δφ To complete the rotation angle of the driving wheel in one meshing cycle; Δλ Is the angle difference of driving wheel when two adjacent teeth start to mesh.

After processing the finite element calculation results when the load M=120 N · m, the curve of the contact force of the 3~5 pairs of teeth with time in Figure 4 is obtained, as shown in Figure 7. Will get Δφ And Δλ The value of can be substituted into the formula to calculate the coincidence degree under the current load.

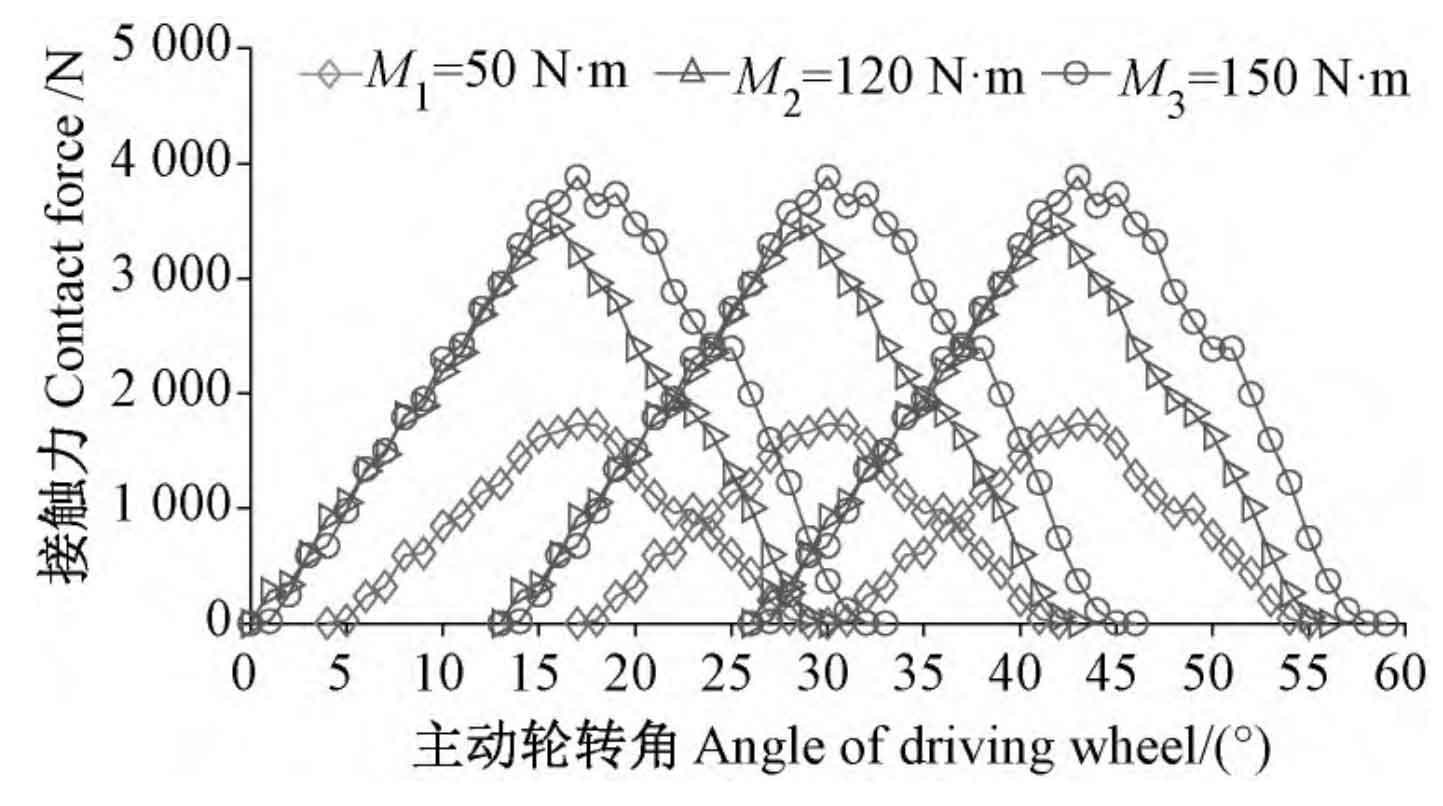

In order to explore the influence of different loads on the coincidence degree, the contact forces of three pairs of teeth under three loads are calculated, and the results are shown in Figure 8. Where, M1=50 N · m, M2=120 N · m, M3=150 N · m. Using the same formula, the coincidence degree under three loads is 1 923, 2.307 and 2 538。 It can be seen that with the increase of load, the coincidence degree of double-arc spiral bevel gear increases.