Introduction

Screw gear systems, known for their ability to transmit motion and power efficiently, are integral components in modern machinery. They are widely used in various industries, including automotive, aerospace, manufacturing, and robotics. This article provides a comparative analysis of different screw gear systems, focusing on their design, performance characteristics, material selection, and applications. The aim is to offer a comprehensive understanding of how screw gear systems are utilized and optimized in contemporary mechanical engineering.

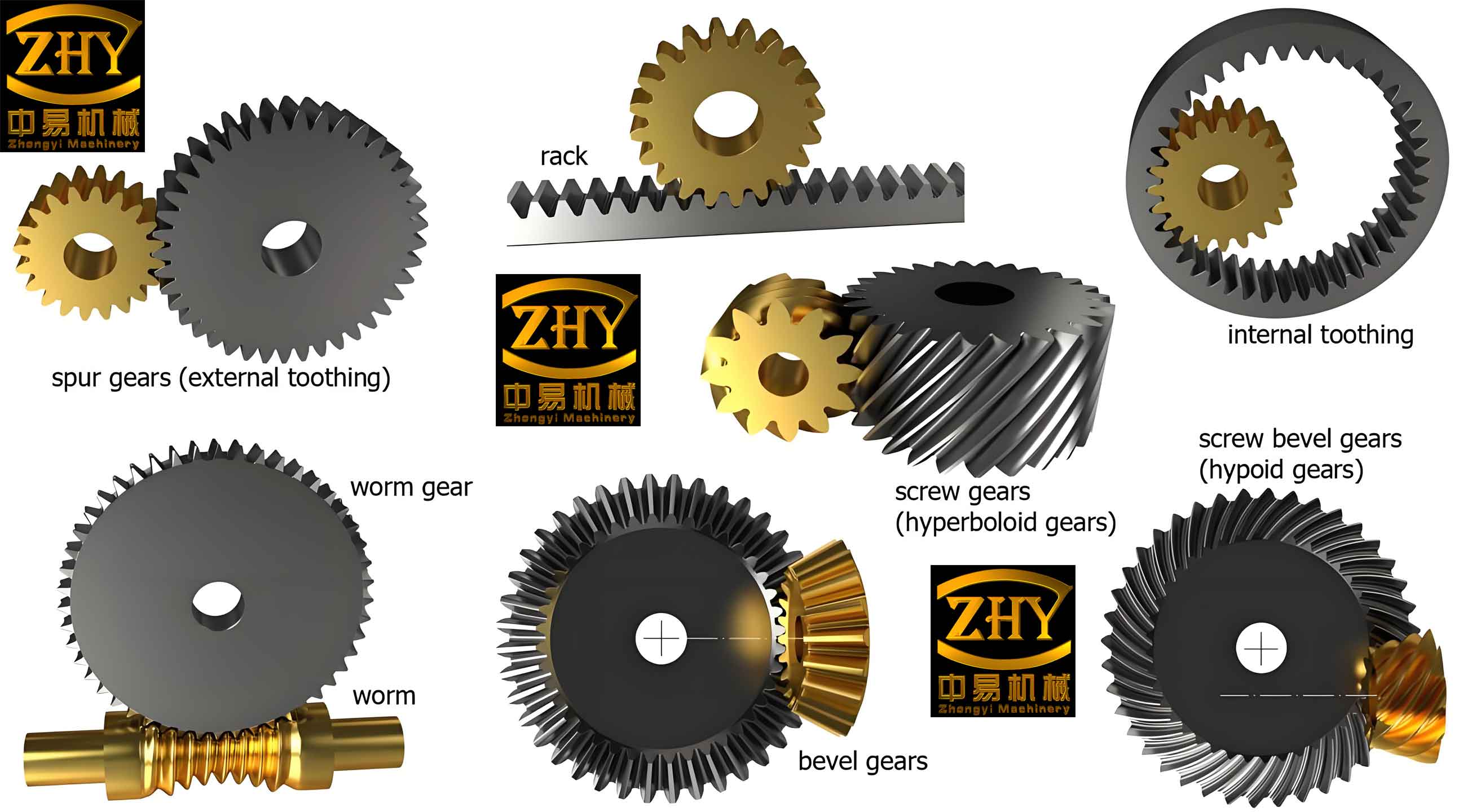

Types of Screw Gear Systems

Screw gear systems come in various forms, each designed to meet specific operational requirements. The most common types include worm gear, helical gear, and bevel gear.

Worm Gear

Worm gear consist of a worm (resembling a screw) that meshes with a worm wheel. They are known for their high torque and compact design.

Advantages

- High reduction ratios

- Smooth and quiet operation

- Self-locking capabilities

Disadvantages

- Lower efficiency compared to other gear

- Higher heat generation

Helical Gear

Helical gear has angled teeth that engage more gradually than spur gear, resulting in smoother and quieter operation. They can transmit motion between parallel or non-parallel shafts.

Advantages

- High efficiency

- Smooth and quiet operation

- Greater load capacity

Disadvantages

- Axial thrust generation

- More complex manufacturing process

Bevel Gear

Bevel gear is conically shaped gear that transmit motion between intersecting shafts, typically at right angles.

Advantages

- Efficient power transmission at various angles

- High torque capability

- Versatile design options

Disadvantages

- Complex manufacturing process

- Limited to specific angle applications

Table 1: Comparative Overview of Screw Gear Types

| Gear Type | Advantages | Disadvantages | Common Applications |

|---|---|---|---|

| Worm Gear | High reduction ratios, self-locking | Lower efficiency, higher heat | Lifts, conveyors, tuning devices |

| Helical Gear | High efficiency, smooth operation | Axial thrust, complex manufacturing | Automotive transmissions, robotics |

| Bevel Gear | Efficient at various angles, high torque | Complex manufacturing, specific angles | Differential drives, turbines |

Performance Characteristics

Efficiency

Efficiency is a critical factor in gear systems, influencing energy consumption and heat generation. Helical gear typically offer the highest efficiency due to their gradual tooth engagement and minimal friction. Worm gear, while providing high torque, often suffer from lower efficiency due to greater sliding contact between the worm and the worm wheel.

Load Capacity

Load capacity determines how much force a gear system can handle before failure. Bevel gear and helical gear generally exhibit higher load capacities due to their robust design and material usage. Worm gear, although compact, may not handle as much load without increased wear and tear.

Noise and Vibration

Noise and vibration levels are essential considerations, especially in applications where quiet operation is crucial. Helical gear is preferred for their smooth and quiet operation, while worm gear also offer quiet performance but at the expense of efficiency. Bevel gear, although efficient, can be noisier if not properly lubricated and maintained.

Table 2: Performance Characteristics of Screw Gear Systems

| Characteristic | Worm Gear | Helical Gear | Bevel Gear |

|---|---|---|---|

| Efficiency | Moderate to Low | High | High |

| Load Capacity | Moderate | High | High |

| Noise and Vibration | Low | Very Low | Moderate |

Material Selection

The choice of material for screw gear significantly affects their performance, durability, and cost. Common materials include steel, cast iron, bronze, and plastics.

Steel

Steel is the most widely used material for screw gear due to its excellent strength, hardness, and wear resistance. Alloy steels and tool steels are often used for high-performance applications requiring superior mechanical properties.

Cast Iron

Cast iron offers good machinability and damping properties, making it suitable for applications where noise reduction is important. It is also cost-effective but less durable than steel.

Bronze

Bronze is known for its excellent wear resistance and low friction, making it ideal for high-load and high-speed applications. It is more expensive than steel and cast iron but provides better performance in harsh environments.

Plastics

Plastics, such as nylon and acetal, are used in applications requiring lightweight and corrosion-resistant gear. They are suitable for low-load applications and offer the advantage of quieter operation.

Table 3: Material Properties for Screw Gear

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, hardness, wear resistance | High-performance gears, heavy-duty applications |

| Cast Iron | Good machinability, damping properties | Noise-sensitive applications |

| Bronze | Excellent wear resistance, low friction | High load, harsh environments |

| Plastics | Lightweight, corrosion resistance | Lightweight, corrosion-prone applications |

Applications of Screw Gear Systems

Automotive Industry

In the automotive industry, helical and bevel gear is extensively used in transmissions, differentials, and steering systems. Their high efficiency and load capacity make them ideal for handling the power and torque demands of modern vehicles.

Aerospace Industry

Aerospace applications require gears with high strength-to-weight ratios and excellent reliability. Worm gear is used in aircraft control systems due to their compact size and self-locking capabilities, while helical gear is found in various power transmission systems.

Industrial Machinery

Screw gear is critical components in industrial machinery, including conveyors, lifts, and packaging equipment. Worm gear provide the necessary torque and self-locking features for heavy-duty applications, while helical and bevel gear is preferred for their efficiency and load-handling capabilities.

Robotics

Robotics applications demand precision, smooth operation, and compact design. Helical gear is commonly used in robotic arms and actuators due to their quiet operation and high efficiency. Worm gear is also employed in robotic joints where space is limited, and self-locking is advantageous.

Table 4: Applications of Screw Gear Systems

| Industry | Common Gear Types | Key Requirements |

|---|---|---|

| Automotive | Helical, Bevel | High efficiency, load capacity, durability |

| Aerospace | Worm, Helical | Strength-to-weight ratio, reliability |

| Industrial Machinery | Worm, Helical, Bevel | Torque, efficiency, robustness |

| Robotics | Helical, Worm | Precision, smooth operation, compactness |

Comparative Analysis

Efficiency and Performance

Helical gear outperform worm and bevel gear in terms of efficiency, making them ideal for applications where energy conservation is crucial. However, worm gear offer unique advantages in terms of torque and self-locking capabilities, making them suitable for specific applications despite their lower efficiency. Bevel gear strike a balance, offering efficient power transmission at various angles but requiring precise manufacturing and maintenance.

Durability and Maintenance

Steel and bronze are preferred materials for their durability and wear resistance. Regular maintenance, including lubrication and inspection, is essential to ensure the longevity of screw gear systems. Worm gear, with their higher friction, require more frequent maintenance compared to helical and bevel gear.

Noise and Vibration

Helical gear provide the quietest operation, which is crucial in applications such as automotive transmissions and robotics. Bevel gear, while efficient, can produce more noise if not properly lubricated. Worm gear offer a compromise, with moderate noise levels but lower efficiency.

Future Trends

Advanced Materials

The development of advanced materials, such as composites and nanomaterials, promises to enhance the performance and durability of screw gear. These materials offer superior strength-to-weight ratios and improved wear resistance, making them ideal for demanding applications.

Smart Manufacturing

The integration of smart manufacturing technologies, such as additive manufacturing and digital twins, allows for more precise and customized gear production. These technologies enable the creation of complex geometries and optimized designs that enhance the performance of screw gear systems.

Sustainability

There is a growing focus on sustainability in gear manufacturing. This includes the use of environmentally friendly materials and processes, as well as the development of recyclable and biodegradable gears. Sustainable manufacturing practices aim to reduce the environmental impact of gear production and extend the lifespan of gear systems.

Table 5: Future Trends in Screw Gear Systems

| Trend | Description | Potential Benefits |

|---|---|---|

| Advanced Materials | Composites, nanomaterials | Superior performance, durability |

| Smart Manufacturing | Additive manufacturing, digital twins | Precision, customization, efficiency |

| Sustainability | Environmentally friendly materials and processes | Reduced environmental impact, recyclability |

Conclusion

Screw gear systems are essential components in modern machinery, offering various advantages in terms of efficiency, load capacity, and noise reduction. The choice of gear type, material selection, and manufacturing process significantly impact their performance and suitability for specific applications. Advances in material science and manufacturing technologies continue to drive the evolution of screw gear systems, enhancing their capabilities and expanding their range of applications. Understanding the comparative strengths and weaknesses of different screw gear systems is crucial for optimizing their use in contemporary mechanical engineering.