1. Test purpose

Verify the influence of different pre heat treatment methods on the deformation of final carburized helical cylindrical gear.

2. Test conditions

Test equipment:

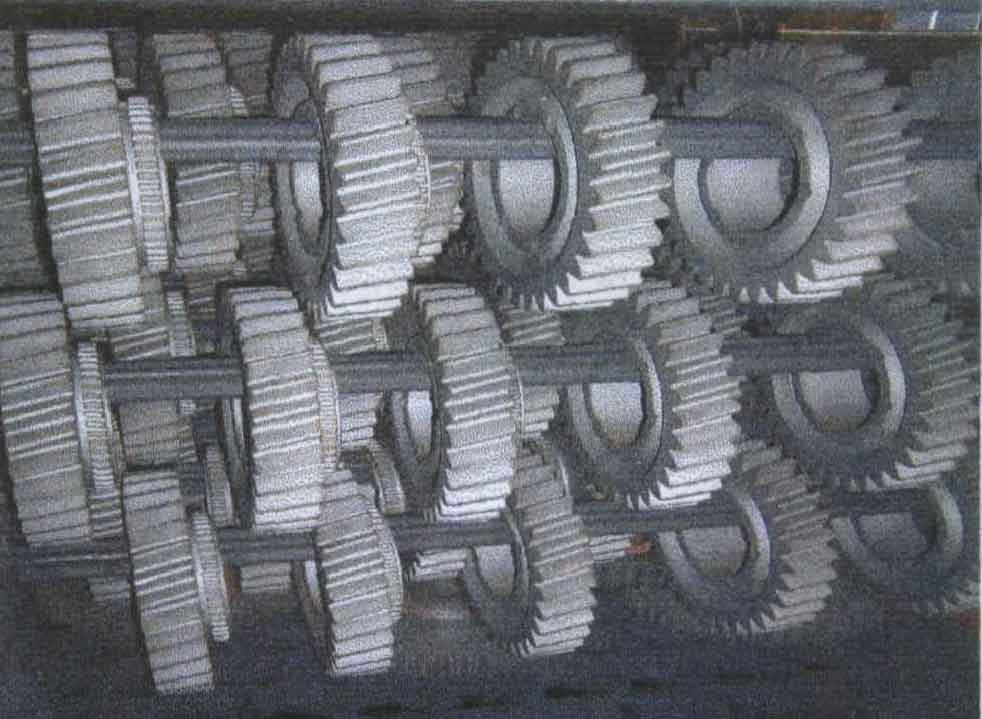

Pre heat treatment equipment: ordinary normalizing adopts ordinary box resistance furnace: isothermal annealing is carried out on the isothermal annealing production line of ZHY gear (Fig. 1);

Carburizing and quenching equipment: aichelin4-2 multipurpose furnace (Fig. 2);

Inspection equipment:

Hardness test: hb-3000 Brinell hardness tester, hrc-150a Rockwell hardness tester;

Effective hardening layer depth inspection equipment: yang-700 microhardness tester;

Metallographic examination: xb-3 ordinary metallographic microscope;

Micrometer, etc.

3. Sample selection and process parameters

| Name | Drawing No. | Material Science | Gear module | Number of teeth | Spline modulus | Number of teeth | Accuracy |

| One speed gear wheel | 1701330 | 20CrMnTiH | 6 | 38 | 1.5 | 82 | Level 6 |

Test part: 9t one speed helical cylindrical gear (see Table 1 and figure 3)

Processing flow: helical cylindrical gear forging – pre heat treatment – turning, gear hobbing – carburizing, quenching and tempering – shot blasting – small amount of grinding (inner space and surface grinding)

Process parameters: pre heat treatment process

Normalizing process: 930 ℃ x3h, spreading air cooling;

Isothermal annealing: 960 ℃ x3h, uniformly cool to about 560 ℃ within 6.5 minutes, keep the temperature at this temperature for 4h, and continue air cooling after air cooling to about 200 ℃ (see Fig. 4)

After pre heat treatment, the gear blank of helical cylindrical gear shall be marked and sent to machining. After machining, it shall be marked and returned to heat treatment for carburization and quenching at the same time;

| Section | Temperature rise and insulation | Temperature and carbon potential | Strong infiltration | Spread | Cooling and carbon reduction potential | Quenching oil temperature | Tempering |

| Temperature (℃) | 850 | 930 | 930 | 930 | 830 | 120 | 200 |

| Carbon potential (%) | 0.4 | 0.6 | 1.2 | 0.9 | 0.8 | — | — |

| Time (h) | 0.5 | 0.5 | 2.5 | 2 | 0.5 | — | 4 |

Carburizing and quenching process: charging method: hanging (see Figure 5), carburizing process: (see Table 2 or figure 6).