Taking the large spiral bevel gear wheel of the same batch of automobile drive axle as an example, after the heat treatment of the spiral bevel gear, the number of sample elements for self-service method is selected as 5 and 10 for self-service sampling. The data of each measurement sequence point detected shall be statistically calculated to calculate its mean value.

The mean difference surface of tooth surface deviation is constructed by the mean value of self-service samples at each measurement sequence point. The mean value and variance of self-service samples at each measurement sequence point of tooth surface deviation of spiral bevel gears are solved by the self-service mathematical calculation model.

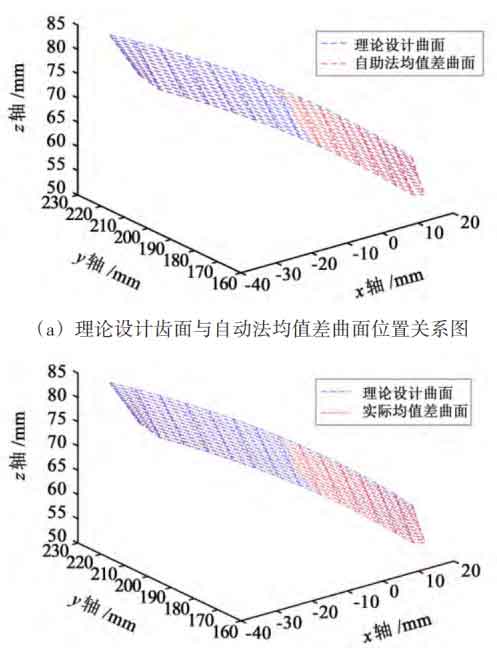

Using the self-help estimation model of tooth surface deviation of spiral bevel gears and the reconstruction theory of mean difference surface of actual tooth surface deviation, the actual tooth surface is reconstructed and the tooth surface of mean difference surface of self-help method is reconstructed according to the tooth surface error of spiral bevel gears calculated by the self-help statistical model.

After NURBS surface reconstruction, the relative position relationship between the actual tooth surface and the theoretical design tooth surface of the mean difference surface is shown in the figure.