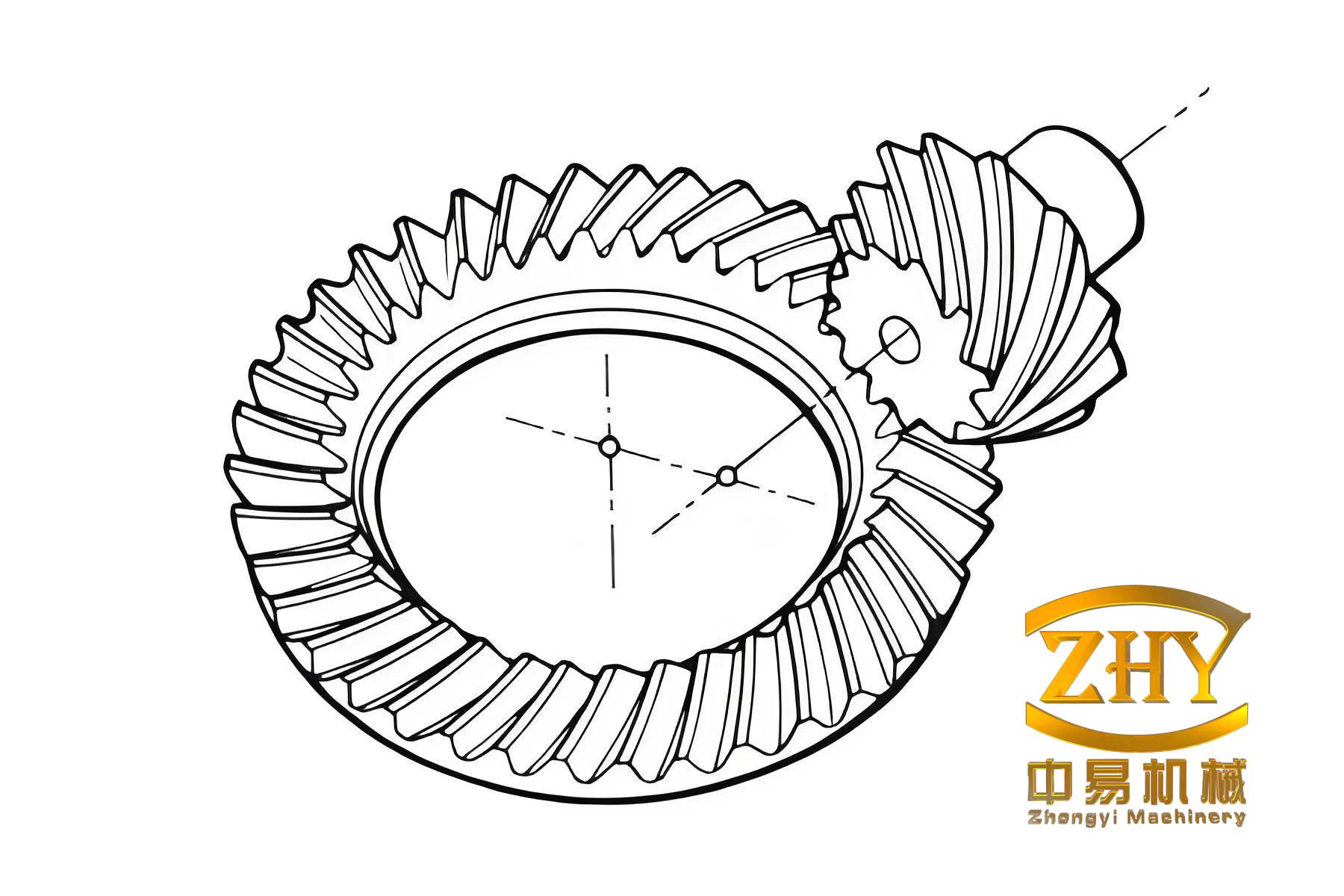

As critical components within automotive final drive axles, hypoid gears are fundamental to torque transmission and speed reduction. The performance, durability, and acoustic behavior of a gear set are intrinsically linked to the quality and consistency of the gear tooth contact pattern under load. This contact pattern is highly sensitive to geometrical deviations introduced during manufacturing, with heat treatment being a primary contributor to uncontrolled dimensional changes. Distortion during carburizing and quenching processes directly induces tooth flank form errors, modifies gear tooth geometry, and leads to significant shifts in the loaded contact area. This often results in elevated transmission noise, reduced load-carrying capacity, premature failure, and high scrap rates. Therefore, a profound understanding of the distortion mechanisms in hypoid gears and their quantifiable impact on meshing behavior is paramount for process optimization and quality assurance in high-volume manufacturing.

The thermal processing of hypoid gears, particularly the quenching phase, is governed by complex interactions between thermal stress and transformation stress. These stresses arise from non-uniform temperature distribution and sequential phase transformations within the component. The intricate geometry of hypoid gears—featuring varying cross-sections from the toe to the heel and from the root to the tip—exacerbates this non-uniformity. When gears are stacked for batch processing, heat exchange with the quenching medium is further complicated, leading to characteristic distortion modes. A common and critical distortion for the large ring gear (driven gear) is face plane warping, often manifesting as a “crowning” or “dishing” effect where the central region deforms relative to the outer rim. This warping directly translates into alterations of the tooth flank topography, deviating it from the meticulously designed theoretical surface. The primary distortion modes in heat-treated hypoid gears can be summarized as follows:

| Distortion Mode | Primary Cause | Effect on Gear Geometry |

|---|---|---|

| Face Plane Warping (Crowning) | Differential cooling rates between the thick web center and thinner rim; transformation sequence. | Changes effective pressure angle and lead across the face width; introduces “crowning” to the tooth trace. |

| Tooth Helix Angle Change | Non-uniform volumetric expansion from martensitic transformation coupled with residual stress relaxation. | Causes lead error; gear teeth exhibit a tendency to “straighten” or alter their spiral. |

| Tooth Profile (Pressure Angle) Change | Differential cooling between tooth tip (thin) and root (thick) regions. | Alters the involute or octoidal form, changing the pressure angle locally. |

| Tooth Thickness Increase | Overall volumetric expansion associated with the austenite-to-martensite transformation. | Reduces designed backlash; can lead to binding if excessive. |

| Bore & Back Face Distortion | Thermal gradients and constraints during quenching. | Affects gear alignment and mounting in the housing, indirectly influencing meshing. |

The fundamental driver of distortion is the stress evolution during quenching. The total stress $\sigma_{total}$ at any point can be considered a superposition of thermal stress $\sigma_{th}$ and transformation stress $\sigma_{tr}$:

$$

\sigma_{total} = \sigma_{th} + \sigma_{tr}

$$

Thermal stress arises from constrained thermal contraction during cooling and is proportional to the temperature gradient $\nabla T$, the coefficient of thermal expansion $\alpha$, and the elastic modulus $E$. A simplified representation for the thermal stress component is:

$$

\sigma_{th} \propto -E \cdot \alpha \cdot \nabla T

$$

During the martensitic transformation, which involves a crystallographic shear and volume expansion (typically 1-4%), transformation stress develops. This stress is a function of the volume fraction of martensite $V_m$, the transformation strain $\varepsilon^{tr}$, and the yield strength of the phases involved. The interaction between these stresses determines the final plastic deformation. Initially, the thinner sections (tooth tips, rim edges) cool faster, transforming first. Their expansion is constrained by the hotter, austenitic core, leading to complex stress states. Later, as the core transforms, its expansion is constrained by the already hardened case, often inducing beneficial compressive residual stresses at the surface but also contributing to the final distorted shape.

The consequence of this distortion is a systematic deviation of the manufactured tooth flank from its theoretical (pre-heat treat) geometry. To analyze the impact on meshing, the concept of flank topography error mapping is essential. Modern gear inspection machines, like the Gleason GMM series, evaluate the flank by probing a grid of points (e.g., 45 points: 5 along the profile height x 9 along the face width). The measured deviation $\delta_{ij}$ at each grid point $(i,j)$ represents the normal direction error from the theoretical surface. For a pair of mating hypoid gears, the conjugate action is predicated on a specific, theoretically constant normal backlash between corresponding points on the pinion and gear flanks.

Let $L^{theory}_{ij}$ be the theoretical normal backlash at a corresponding mesh point pair. After heat treatment, the pinion flank (e.g., concave drive side) has an error $\delta^{P}_{ij}$, and the gear flank (convex drive side) has an error $\delta^{G}_{ij}$. The actual normal backlash $L^{actual}_{ij}$ at this point pair is therefore:

$$

L^{actual}_{ij} = L^{theory}_{ij} – (\delta^{P}_{ij} + \delta^{G}_{ij})

$$

The change or error in backlash, $\Delta L_{ij}$, is:

$$

\Delta L_{ij} = L^{actual}_{ij} – L^{theory}_{ij} = – (\delta^{P}_{ij} + \delta^{G}_{ij})

$$

Thus, a positive sum of flank errors ($\delta^{P}_{ij} + \delta^{G}_{ij} > 0$) results in a negative $\Delta L_{ij}$, meaning the local backlash is smaller than designed. Under load, areas with smaller backlash will experience contact earlier and under higher local pressure, causing the contact pattern to shift towards these regions. Conversely, areas with larger-than-designed backlash ($\Delta L_{ij} > 0$) may not come into contact at all under nominal load.

The final contact pattern is determined by the elastic deformation of the gears under load, conforming to this modified topography. The condition for a point on the flank pair to be within the contact ellipse under a specified load and misalignment is governed by a deformation compatibility equation. For a corresponding point pair $k$-$k’$, let $\tau_{kk’}$ be the total normal approach (elastic deformation) of the two flanks at that point under load. Contact occurs where the initial separation (backlash) plus the local elastic deflections equals the rigid body approach. This can be expressed as:

$$

L^{actual}_{kk’} + \varepsilon^{P}_k + \varepsilon^{G}_{k’} = \tau_{kk’}

$$

where $\varepsilon^{P}_k$ and $\varepsilon^{G}_{k’}$ are the local contact deformations at the points on the pinion and gear, respectively. The flank error-driven backlash variation $\Delta L_{ij}$ directly feeds into $L^{actual}_{kk’}$, thereby dictating which grid points satisfy the contact condition and ultimately determining the size, shape, and location of the contact pattern.

To empirically validate this theoretical framework and quantify the distortion effects, a controlled study was conducted. A batch of production hypoid gears (pinion and ring gear sets) was selected. Each gear was individually identified, and a specific tooth on both the pinion and gear was marked for consistent pre- and post-heat-treatment measurement. The experimental parameters are summarized below:

| Parameter | Description |

|---|---|

| Gear Set Type | Automotive rear axle hypoid gear set (offset ~30mm) |

| Sample Size | 36 matched pinion-gear pairs |

| Heat Treatment Process | Gas carburizing (927°C) followed by oil quenching |

| Pre-Treatment Measurement | Flank topography (45-point grid) on Gleason GMM350 |

| Post-Treatment Measurement | Same tooth flank topography re-measured on GMM350 |

| Contact Pattern Check | Rolling test under light load with marking compound using a Gleason 600HTT tester |

The analysis of the 45-point grid data before and after heat treatment revealed clear and systematic trends in flank geometry change. For the pinion, the dominant changes were statistically consistent across the sample batch. The following table summarizes the average change in key flank parameters for the marked pinion teeth:

| Flank Parameter | Pre-HT Range | Post-HT Range | Average Change (Magnitude & Direction) |

|---|---|---|---|

| Tooth Thickness (µm) | -18 to -3 (undersize) | +5 to +30 (oversize) | Increase of ~25 µm |

| Concave Flank Pressure Angle (arc-min) | -1 to +2 | +10 to +14 | Increase of ~11 arc-min |

| Convex Flank Pressure Angle (arc-min) | -2 to +2 | -1 to +3 | Negligible systematic change |

| Concave Flank Spiral Angle (arc-min) | -1 to +1 | -6 to +3 | Decrease of ~5 arc-min (Toe-ward shift) |

| Convex Flank Spiral Angle (arc-min) | +1 to +2 | -2 to +4 | Decrease of ~4 arc-min (Toe-ward shift) |

These measurements confirm the theoretical distortion mechanisms. The significant increase in tooth thickness is a direct result of the volumetric expansion from martensite formation. The pronounced increase in the concave flank’s pressure angle suggests differential contraction between the tip and root during quenching of that specific flank geometry. The consistent decrease in spiral angle (lead becoming less progressive) across both flanks indicates a “straightening” tendency of the twisted tooth, likely due to the relief of machining-induced residual stresses and the specific manner in which transformation stresses develop in the asymmetrical tooth cross-section.

Applying the backlash error analysis $\Delta L_{ij} = – (\delta^{P}_{ij} + \delta^{G}_{ij})$ to the post-heat-treatment 45-point error maps of a sample pair yields a predictive contact shift vector field. For the drive side (pinion concave / gear convex), the computed $\Delta L_{ij}$ values typically showed a pattern where the errors were more negative (smaller actual backlash) in the central region of the flank and towards the toe. This computationally predicted that the post-heat-treatment contact pattern would migrate from the heel-and-top area towards the center and toe of the tooth flank.

The rolling tests on the 600HTT machine provided definitive visual confirmation. Pre-heat-treatment contact patterns, established from gears cut to nominal “green” geometry, were consistently located towards the heel and slightly biased towards the top (face cone) of the gear tooth. After heat treatment, the contact patterns on the same gear sets, assembled at the same nominal position, showed a pronounced and consistent shift. The pattern moved inward along the face width towards the center and downward along the profile height towards the midpoint. This empirical observation aligned perfectly with the prediction derived from the flank error grid analysis and the underlying backlash error calculation. The shift parameters can be quantified as follows:

| Contact Zone Parameter | Pre-Heat Treatment Characteristic | Post-Heat Treatment Characteristic | Shift Direction |

|---|---|---|---|

| Face Width Location | Biased towards Heel | Centered or slightly Toe-biased | Heel → Toe |

| Profile Height Location | Biased towards Top (Tip) | Centered on Active Profile | Top → Center |

| Pattern Size & Shape | More elongated | Often more compact/rounded | – |

| Pattern Consistency (Pair-to-Pair) | High | Reduced Variability Increased | – |

The study conclusively demonstrates that heat treatment distortion in hypoid gears is not random but follows predictable physical principles linked to geometry and process dynamics. The primary mechanism involves the generation and interaction of thermal and transformation stresses during quenching, leading to systematic changes in tooth thickness, pressure angle, and spiral angle. These geometrical deviations directly alter the local normal backlash between mating flanks, as described by the equation $\Delta L_{ij} = – (\delta^{P}_{ij} + \delta^{G}_{ij})$. This modified backlash map dictates the final loaded contact pattern via elastic deformation compatibility.

The experimental validation using flank topography measurement and rolling tests confirmed the theoretical model. The contact pattern on the gear convex flank consistently migrated from the heel-and-top region towards the tooth center post-heat-treatment. Furthermore, while the absolute magnitude of distortion was significant, its direction and trend showed remarkable consistency across a production batch. This consistency is a crucial finding; it implies that the distortion is controllable and predictable. Therefore, the pre-heat-treatment (green) gear geometry can be proactively modified through a compensation process often called “anti-deflection” or “pre-correction” in the gear cutting stage. By introducing deliberate, opposite errors into the green tooth flank—such as a slight bias of the contact towards the toe and root, or modifying the pressure angle and lead slope—the subsequent heat treatment distortion can be engineered to bring the final geometry and contact pattern back to the desired nominal target.

This research provides a robust framework for analyzing and compensating for heat treatment effects in hypoid gears. Future work can focus on developing quantitative predictive models using finite element analysis (FEA) to simulate the quenching process for specific hypoid gear geometries, linking process parameters (quenchant temperature, agitation, fixturing) directly to predicted flank error maps $\delta_{ij}$. This would enable a closed-loop digital manufacturing approach for high-precision hypoid gears, minimizing trial-and-error and ensuring optimal contact pattern quality and consistency directly from the production line.

The relationship between green machining parameters and final post-heat-treat contact location can be modeled via a multi-variable regression based on the distortion vectors. If we define a contact center shift vector $\vec{S}$ with components in face width ($S_F$) and profile height ($S_H$), it can be expressed as a function of the dominant green geometry parameters:

$$

\vec{S} = \begin{bmatrix} S_F \\ S_H \end{bmatrix} = f(G_{PA}, G_{LA}, G_{Crow}, G_{Thick})

$$

where $G_{PA}$ is the green pressure angle offset, $G_{LA}$ is the green lead (spiral angle) offset, $G_{Crow}$ is the green crowning amount, and $G_{Thick}$ is the green tooth thickness. The function $f$ can be linearized for small changes around a nominal setting, derived from empirical data like that collected in this study, forming the basis for a practical compensation algorithm in manufacturing.