The meshing error of gear teeth mainly comes from the error caused by gear processing and installation. Machining error mainly refers to the axis error of the central element in the composite planetary gear mechanism in the figure, and the axis error of the coaxial gear center in the parallel shaft gear; Installation error mainly refers to the error caused by the installation of planetary carrier, large and small sun gear, large and small planet gear and ring gear center in composite planetary mechanism and the installation error of planetary gear center in parallel shaft gear.

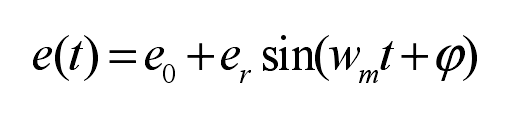

Because of these errors, the relative meshing displacement of planetary gear pair in the system will deviate. Therefore, the comprehensive meshing error can be expressed as sinusoidal function:

Where, e (T) is the function of the comprehensive meshing error of planetary gear teeth with time; E0 and ER are the constant value and amplitude of gear tooth error; WM is the meshing frequency; ZT is the meshing cycle of planetary gear; N is the speed; Z is the number of teeth; φ Is the phase angle.