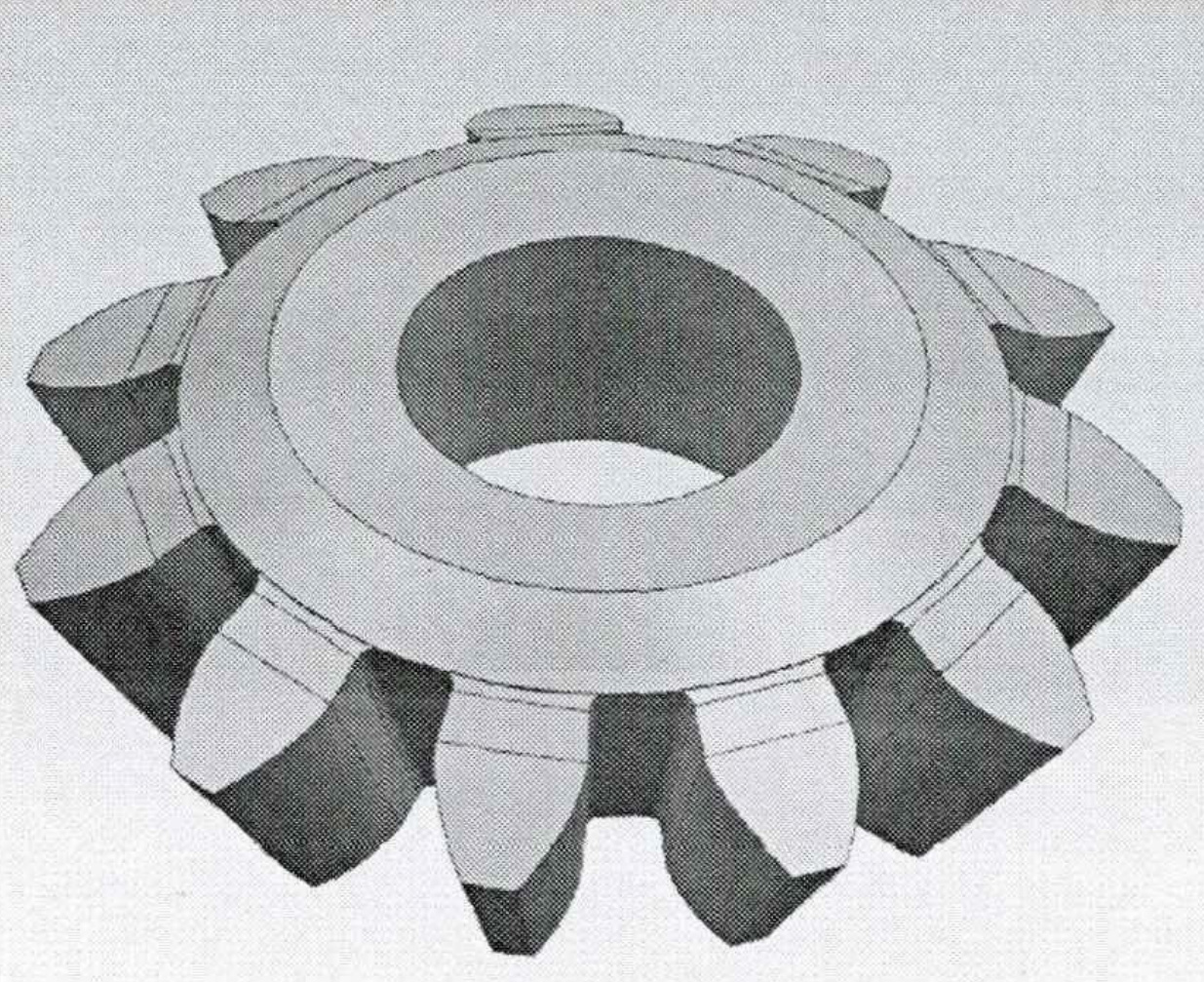

The closed precision forging process of spur bevel gear is simulated and analyzed, the influence law of its process parameters on the forming quality is studied, the elastic deformation of the die and the elastic recovery deformation of the forging are analyzed, and the compensation design method of the die tooth profile cavity size is established to realize the accurate forming of spur bevel gear.

- for straight bevel gear forgings, the forming load index value gradually decreases with the increase of punching skin thickness. With the increase of friction coefficient, punch speed and lower blind hole height, the forming load index increases gradually.

- the lower female die is subjected to uneven and outward diffused forming reaction force of spur bevel gear forgings. Moreover, due to the shape characteristics of spur bevel gears, the direction of most of the forces is perpendicular to the tooth top surface of the gears, resulting in the deformation and flow direction of the die metal materials from the inside of the die cavity to the outside of the die cavity along the direction perpendicular to the tooth top of the gears. At the same time, the elastic deformation of the die cavity increases gradually from the small end to the large end.

- the average springback of the big end of the spur bevel gear in the radial direction (i.e. direction) is less than that of the small end of the gear. In the axial direction (i.e. direction), from the middle part of the small end to the big end of the gear to the big end of the gear, the average springback gradually increases.

- from the top of the tooth profile to the root of the tooth, the average springback of the straight bevel gear in the radial direction (and direction) gradually decreases, that is, the top of the tooth contributes greatly to the increase of the gear diameter. At the same time, the average springback in the axial direction decreases with the change of the tooth profile from the top to the root.