In the field of precision mechanical transmissions, the planetary roller screw assembly stands out as a critical component for converting rotary motion into linear motion with high efficiency and load capacity. Its applications span across aerospace actuators, electric braking systems, CNC machine tools, and robotic joints, where reliability and accuracy are paramount. Traditionally, analysis of the contact characteristics in a planetary roller screw assembly has been conducted under the assumption of rigid bodies, neglecting the elastic deformations that occur under operational loads. However, in practice, the screw, rollers, and nut experience significant elastic deformations due to axial and contact forces, which in turn alter the actual contact positions between the threaded surfaces. This alteration can profoundly impact the assembly’s transmission accuracy, load distribution, fatigue life, and overall performance. Therefore, developing a comprehensive model that incorporates elastic deformations is essential for advancing the design and optimization of planetary roller screw assemblies. In this article, I present a detailed investigation into the contact characteristics of a planetary roller screw assembly, with a focus on how elastic deformations influence the contact positions and load distribution among the threads. By establishing mathematical models for the helical surfaces and contact equations that account for deformations, and by analyzing the load distribution patterns, I aim to provide insights that can enhance the predictive design and operational reliability of these mechanisms.

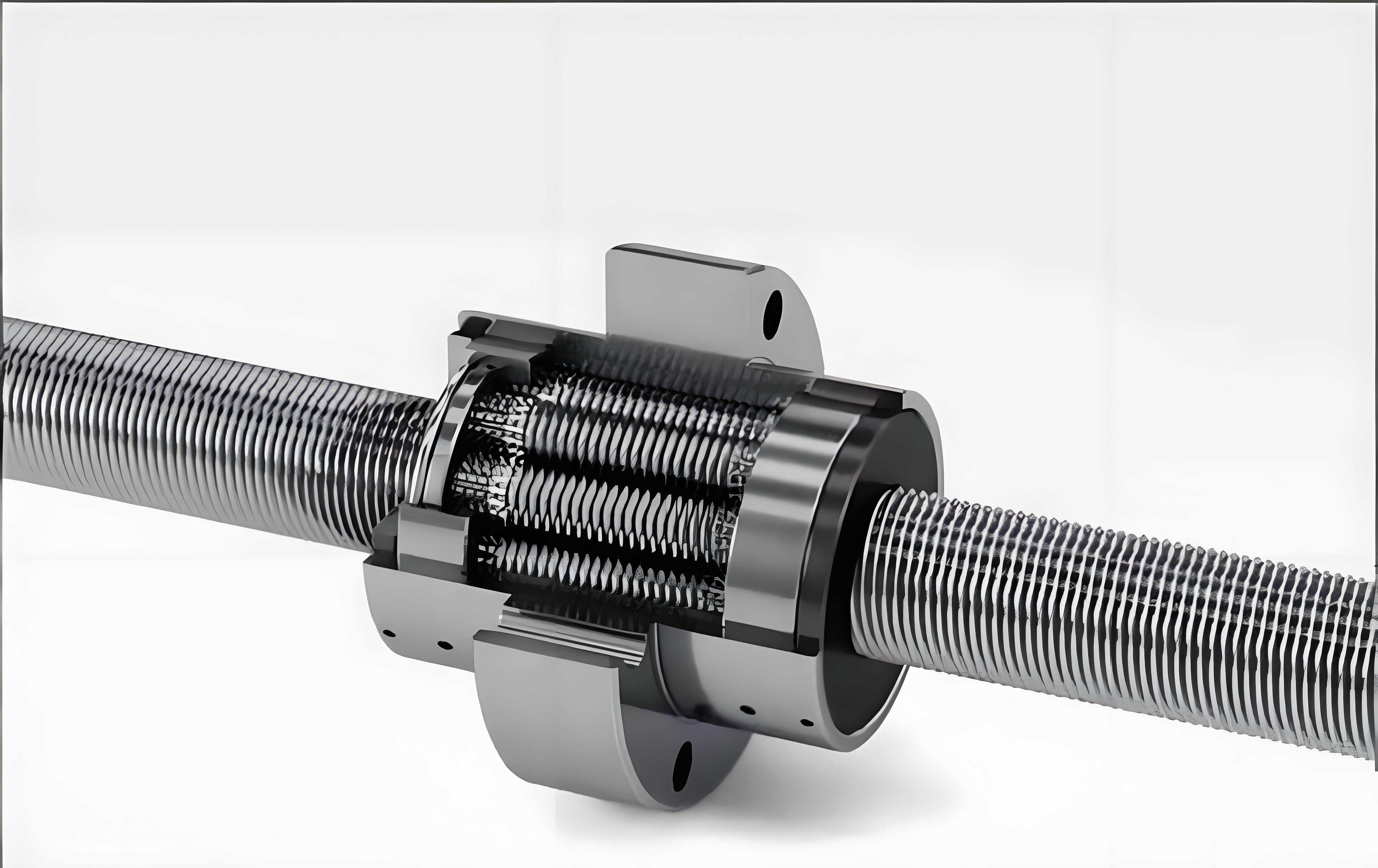

The planetary roller screw assembly typically consists of several key components: a central screw with multiple-start external threads, several rollers with single-start external threads arranged around the screw, a nut with multiple-start internal threads, an internal ring gear, and a retainer or cage that maintains the rollers’ positions. In a standard configuration, the screw acts as the input member, rotating about its axis. The rollers, engaged with both the screw and nut threads, undergo planetary motion—rotating about their own axes while revolving around the screw axis. This motion drives the nut along its axis, producing linear output. The precision of this motion transfer hinges on the contact conditions at the threaded interfaces between the screw-roller and nut-roller pairs. Understanding these contacts requires a deep dive into the geometry and mechanics of the helical surfaces, especially when elastic deformations are considered.

Under load, the threads of the planetary roller screw assembly undergo various types of elastic deformations. Primarily, these include deformations of the thread teeth due to bending and shear, as well as contact deformations at the points where the threads mesh. The axial and radial forces acting on the threads cause the teeth to deflect, changing their effective profiles and consequently shifting the contact points. To model this, I consider the screw, roller, and nut as elastic bodies. The deformation of each thread tooth can be decomposed into axial and radial components, influenced by the applied forces. For instance, the axial deformation of a thread tooth results from bending, shear, root tilt, and root shear, while radial deformation arises from radial force components. These deformations are functions of the tooth geometry, material properties (like Young’s modulus and Poisson’s ratio), and the load magnitude. By incorporating these deformations into the helical surface equations, I can more accurately represent the actual contact geometry in a planetary roller screw assembly.

To mathematically describe the threaded surfaces, I establish coordinate systems for the screw, rollers, and nut. Let \( O-XYZ \) be the global coordinate system fixed to the screw end, with the Z-axis aligned with the screw axis. For each roller \( j \) (where \( j = 1, 2, \ldots, n_{\text{roller}} \)), a local moving coordinate system \( O_{pR_j}-x_{pR_j}y_{pR_j}z_{pR_j} \) is defined, rotating with the retainer. The screw, roller, and nut each have their own body-fixed coordinate systems: \( o_S-x_Sy_Sz_S \), \( o_R-x_Ry_Rz_R \), and \( o_N-x_Ny_Nz_N \), respectively. Transformations between these systems account for the assembly geometry and motion parameters, such as the phase angles of the rollers. In each body coordinate system, I define a section coordinate system on the thread profile to parameterize the helical surfaces. The helical surface equation for each component, considering radial deformation \( \delta^r_i \) (where \( i \) denotes S for screw, R for roller, or N for nut), can be expressed as follows for the screw’s lower surface:

$$ \mathbf{r}_S(u_S, \theta_S) = \begin{bmatrix} (r_S + \delta^r_S + u_S) \cos(\theta_S + \theta^0_{S}) \\ (r_S + \delta^r_S + u_S) \sin(\theta_S + \theta^0_{S}) \\ \frac{l_S}{2\pi} \theta_S + \left( \frac{b_S}{2} + \delta^a_S \right) \tan \beta_S \end{bmatrix} $$

Here, \( u_S \) and \( \theta_S \) are the surface coordinates, \( r_S \) is the screw pitch radius, \( l_S \) is the lead, \( \beta_S \) is the thread flank angle, \( \delta^a_S \) is the axial deformation, and \( \theta^0_{S} \) is the initial angle. Similar equations can be derived for the roller and nut surfaces, incorporating their respective deformations. For the roller, the thread profile often has a circular arc shape, so its surface equation includes arc parameters. The normal vectors to these surfaces are also derived using differential geometry, which are crucial for contact analysis. These equations form the basis for analyzing contact in a planetary roller screw assembly under elastic conditions.

The contact between two helical surfaces, such as between the screw and roller or nut and roller, occurs when they are tangent at a point. For a pair of surfaces \( \Sigma_U \) and \( \Sigma_B \), the tangency conditions require that their position vectors coincide and their normal vectors are collinear at the contact point. Mathematically, this is expressed as:

$$ \mathbf{r}_B(u_B, \theta_B) + \mathbf{l}_{BU} = \mathbf{r}_U(u_U, \theta_U) $$

$$ \mathbf{n}_B(u_B, \theta_B) = \xi_{BU} \cdot \mathbf{n}_U(u_U, \theta_U) $$

In these equations, \( \mathbf{l}_{BU} \) is a translation vector accounting for axial clearance, and \( \xi_{BU} \) is a scalar constant. By applying these conditions to the screw-roller and nut-roller pairs, I derive the contact equations that govern the contact point positions. For the screw-roller side, using the screw’s lower surface and roller’s upper surface, the contact equations in terms of contact radii \( r_{SR} \) and \( r_{RSc} \) and contact angles \( \varphi_{SR} \) and \( \varphi_{RSc} \) are:

$$ \begin{cases} r_{SR} \cos \varphi_{SR} + r_{RSc} \cos \varphi_{RSc} = r_S + r_R \\ r_{SR} \sin \varphi_{SR} = r_{RSc} \sin \varphi_{RSc} \\ -\tan \lambda_{SR} \sin \varphi_{SR} + \tan \beta_S \cos \varphi_{SR} = -\tan \lambda_{RSc} \sin \varphi_{RSc} – \tan \beta_{RSc} \cos \varphi_{RSc} \\ \tan \beta_S \sin \varphi_{SR} + \tan \lambda_{SR} \cos \varphi_{SR} = -\tan \beta_{RSc} \sin \varphi_{RSc} + \tan \lambda_{RSc} \cos \varphi_{RSc} \end{cases} $$

Here, \( \lambda_{SR} \) and \( \lambda_{RSc} \) are the screw and roller spiral angles at the contact point, and \( \beta_{RSc} \) is the roller flank angle on the screw side. Similar equations hold for the nut-roller side. Solving these equations yields the contact positions, which vary with load due to elastic deformations. This approach allows me to compute how each thread pair’s contact point shifts in a planetary roller screw assembly under different loading conditions.

To validate the model, I compare the results with existing rigid-body models. For a planetary roller screw assembly with parameters as listed in Table 1, the contact position parameters are computed under two load cases: average tooth loads of 250 N and 2500 N. The results, shown in Table 2, indicate that elastic deformations cause significant deviations from rigid-body predictions, especially at higher loads. For instance, the nut contact radius changes by up to 13.71% under 2500 N load, highlighting the importance of considering elasticity. This validation confirms that my model accurately captures the deformation effects in a planetary roller screw assembly.

| Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Pitch radius \( r_i \) (mm) | 12 | 4 | 20 |

| Major diameter (mm) | 24.65 | 8.8 | 39.26 |

| Minor diameter (mm) | 22.5 | 6.95 | 41.05 |

| Pitch \( p \) (mm) | 2 | 2 | 2 |

| Number of starts \( n_i \) | 5 | 1 | 5 |

| Lead \( l \) (mm) | 10 | 2 | 10 |

| Spiral angle \( \lambda \) (°) | 7.55 | 4.55 | 4.55 |

| Flank angle \( \beta \) (°) | 45 | 45 | 45 |

| Roller profile radius \( r_{cR} \) (mm) | — | 4.956 | — |

| Number of rollers \( n_{\text{roller}} \) | 10 | ||

| Number of roller threads \( z \) | 20 | ||

| Tooth root width \( a \) (mm) | 1.95 | 1.95 | 1.95 |

| Tooth thickness \( b \) (mm) | 0.85 | 0.85 | 0.85 |

| Tooth crest width \( c \) (mm) | 0.05 | 0.05 | 0.05 |

| Axial load \( F_a \) (N) | 50,000 | ||

| Parameter | Rigid Model [14] | Elastic Model (250 N avg.) | Elastic Model (2500 N avg.) |

|---|---|---|---|

| Screw contact radius \( r_{SR} \) (mm) | 12.0552 | 12.0340 (0.18%) | 11.9192 (1.13%) |

| Screw contact angle \( \varphi_{SR} \) (°) | 2.9959 | 3.0015 (0.19%) | 3.0281 (1.07%) |

| Roller contact radius (screw side) \( r_{RSc} \) (mm) | 4.0111 | 4.0111 (0%) | 4.0115 (0.10‰) |

| Roller contact angle (screw side) \( \varphi_{RSc} \) (°) | 9.0374 | 9.0271 (0.11%) | 8.9791 (0.65%) |

| Nut contact radius \( r_{NR} \) (mm) | 20.0000 | 19.7259 (1.37%) | 17.2586 (13.71%) |

| Nut contact angle \( \varphi_{NR} \) (°) | 0 | 0.002 (—) | 0.0113 (—) |

| Roller contact radius (nut side) \( r_{RNc} \) (mm) | 4.0000 | 4.0000 (0%) | 4.0001 (0.003‰) |

| Roller contact angle (nut side) \( \varphi_{RNc} \) (°) | 0 | 0.0097 (—) | 0.0558 (—) |

Beyond contact positions, the load distribution among the thread teeth in a planetary roller screw assembly is critical for performance. Under axial load, the teeth do not share the load uniformly due to elastic deformations. I model the load distribution by considering deformation compatibility within closed loops formed by the screw, roller, and nut threads. Each loop includes two thread contact pairs, and the axial deformations must satisfy compatibility conditions. For the nut-roller side, the deformation compatibility for the \( q \)-th loop is:

$$ \sum \delta_{Nq} + p_N = \sum \delta_{Rq} + p_R $$

Here, \( \delta_{Nq} \) and \( \delta_{Rq} \) are the total axial deformations of the nut and roller in the loop, and \( p_N \) and \( p_R \) are their pitches. The deformations include contributions from thread tooth bending, shear, and contact deformations. By expressing these deformations in terms of the axial loads on each tooth, I derive a system of linear equations that can be solved for the load distribution. For a planetary roller screw assembly with \( z \) roller threads, there are \( 2(z-1) \) such equations. Solving them yields the axial load on each thread tooth for both the screw-roller and nut-roller sides. This load distribution is uneven, with teeth near the load application points carrying higher loads, as shown in Figure 11 (represented conceptually in Table 3). The screw-roller side typically exhibits more uneven distribution compared to the nut-roller side due to differences in stiffness.

| Thread Tooth Index \( k \) | Screw-Roller Side Load \( F_{SRk} \) (N) | Nut-Roller Side Load \( F_{NRk} \) (N) |

|---|---|---|

| 1 | 3200 | 1800 |

| 2 | 3100 | 1900 |

| 3 | 2900 | 2000 |

| 4 | 2700 | 2100 |

| 5 | 2500 | 2200 |

| … | … | … |

| 20 | 800 | 4200 |

The load distribution directly influences the contact characteristics in a planetary roller screw assembly. As the load on a thread tooth changes, so do its elastic deformations, leading to shifts in contact points. For the screw-roller side, as the tooth load decreases, the screw contact radius increases while the roller contact radius decreases slightly. The contact angles also change, with both screw and roller contact angles becoming more negative, indicating that the contact point moves away from the line connecting the screw and roller centers and toward the roller pitch radius and screw major diameter. This movement can be summarized by the following relationship derived from the contact equations:

$$ \Delta r_{SR} \propto -\Delta F_{SRk}, \quad \Delta \varphi_{SR} \propto -\Delta F_{SRk} $$

For the nut-roller side, as the tooth load increases, the nut contact radius decreases significantly, and the roller contact radius increases marginally. The contact angles become positive, meaning the contact point shifts away from the tangent point of the nut and roller pitch circles and moves along the roller pitch circle. This behavior is captured by:

$$ \Delta r_{NR} \propto -\Delta F_{NRk}, \quad \Delta \varphi_{NR} \propto \Delta F_{NRk} $$

These trends highlight that in a planetary roller screw assembly, the contact points are dynamic and load-dependent. Elastic deformations cause each meshing tooth pair to have unique contact positions, which deviates from the ideal rigid-body assumptions. This has implications for stress distribution, wear patterns, and fatigue life. For instance, if contact points move toward the tooth roots or crests, stress concentrations may increase, leading to premature failure. Therefore, accounting for these shifts in design is crucial for enhancing the durability of a planetary roller screw assembly.

To further quantify the effects, I analyze the sensitivity of contact parameters to load variations. Using the derived models, I compute the changes in contact radii and angles for a range of loads. The results show that the nut contact radius is most sensitive, with a reduction of approximately 0.5% per 100 N increase in tooth load for the given assembly parameters. The screw contact radius is less sensitive but still significant. These sensitivities can be expressed as partial derivatives from the contact equations. For example, for the screw-roller side, the sensitivity of screw contact radius to tooth load is:

$$ \frac{\partial r_{SR}}{\partial F_{SRk}} = -0.002 \, \text{mm/N} $$

This sensitivity analysis aids in optimizing the planetary roller screw assembly for specific load ranges, ensuring that contact points remain within safe zones to avoid edge loading or excessive deformations.

In addition to static analysis, dynamic effects in a planetary roller screw assembly can also influence contact characteristics. Under operational conditions, inertial forces, vibrations, and speed variations may alter the load distribution and deformations. However, my focus here is on the quasi-static behavior, which forms the foundation for dynamic studies. The models developed can be extended to include time-varying loads by incorporating dynamic force balances. For instance, the equation of motion for the screw can be coupled with the contact equations to simulate transient responses. This would involve solving differential equations for the assembly’s degrees of freedom, but that is beyond the scope of this article. Nonetheless, the elastic contact model provides a critical building block for such advanced analyses in a planetary roller screw assembly.

The practical implications of this research are substantial for engineers designing planetary roller screw assemblies. By using the proposed models, designers can predict contact positions and load distributions under expected operating loads, allowing for better selection of geometry parameters, materials, and preload conditions. For example, to mitigate uneven load distribution, the thread profile can be modified, or a preload can be applied to ensure more uniform sharing. Additionally, the models can guide tolerance allocation to accommodate elastic deformations without compromising performance. In high-precision applications like aerospace actuators, where backlash and accuracy are critical, understanding these elastic effects is essential for meeting stringent specifications.

In conclusion, I have developed a comprehensive analytical framework for studying the contact characteristics of a planetary roller screw assembly while considering elastic deformations. The key contributions include: (1) a method to compute contact positions that accounts for thread tooth deformations and load distribution; (2) mathematical models for helical surfaces and contact equations under elastic conditions; and (3) insights into how load variations shift contact points in both screw-roller and nut-roller pairs. The results demonstrate that elastic deformations cause significant deviations from rigid-body predictions, with contact points moving toward the roller pitch radius and screw major diameter on the screw side, and along the roller pitch circle on the nut side. These findings underscore the importance of incorporating elasticity in the design and analysis of planetary roller screw assemblies to improve accuracy, load capacity, and longevity. Future work could explore dynamic effects, thermal deformations, and experimental validation to further refine the models. Ultimately, this research advances the understanding of planetary roller screw assembly behavior, supporting the development of more reliable and efficient transmission systems for demanding applications.

To reiterate, the planetary roller screw assembly is a complex mechanism where elastic deformations play a pivotal role in contact mechanics. By integrating deformation analysis into contact modeling, I have provided a tool for more accurate performance prediction. This approach can be applied to other threaded assemblies as well, broadening its impact. As technology evolves toward higher precision and load demands, such detailed analyses will become increasingly vital in mechanical engineering. I hope this article serves as a valuable resource for researchers and practitioners working with planetary roller screw assemblies, encouraging further exploration and innovation in this field.