Gear transmission is the most widely used transmission form in modern machinery. It has the characteristics of high transmission accuracy, high transmission efficiency, reliable operation and long service life. Gear transmission is composed of spur gear, helical gear, bevel gear and other gear pairs. The traditional gear design is mainly based on the engineering algorithms in the industry specifications. Nowadays, with the rapid development of computer technology, the precise design of gear products based on numerical methods becomes possible. For example, the gear meshing simulation based on the Finite Element Method (FEM) is increasingly used in gear design. Helical gears are widely used in various gear transmission systems due to their good stability and strong load carrying capacity during meshing.

In the design and calculation of helical gears, the contact pressure between the teeth, the half-width of the contact belt and the meshing stiffness are all important calculation parameters. The accuracy of the parameters directly determines the reliability of the helical gears in the service process. The meshing simulation based on 3D solid model can accurately give the contact pressure value of helical gear in any meshing phase and its intuitive distribution along the meshing line, and also can obtain high-precision information such as the half-width of the contact belt and the meshing stiffness of the gear teeth. The verification of the mesh independence of contact pressure and half-width of contact zone is the premise of the authenticity of the helical gear contact simulation results. However, due to the strong nonlinearity of the contact problem, the contact pressure and half-width of contact zone results are extremely sensitive to the mesh size of the contact zone. Using traditional methods to verify the mesh independence often requires a lot of calculation time and cost, which greatly reduces the efficiency of the simulation design of helical gear pairs.

In 1881, the German physicist Heinrich Rudolf Hertz studied the elastic deformation of glass lenses under the force that makes them contact with each other. With the help of the comparative analysis between theoretical calculation and experimental observation results, based on the three-point hypothesis, the Hertz contact formula describing the relationship between contact stress, normal loading force, radius of curvature of contact body and elastic modulus was obtained, The three assumptions are: 1) small deformation occurs in the contact area; 2) The contact surface is elliptical; 3) The object in contact can be regarded as an elastic half space, and only distributed vertical pressure acts on the contact surface.

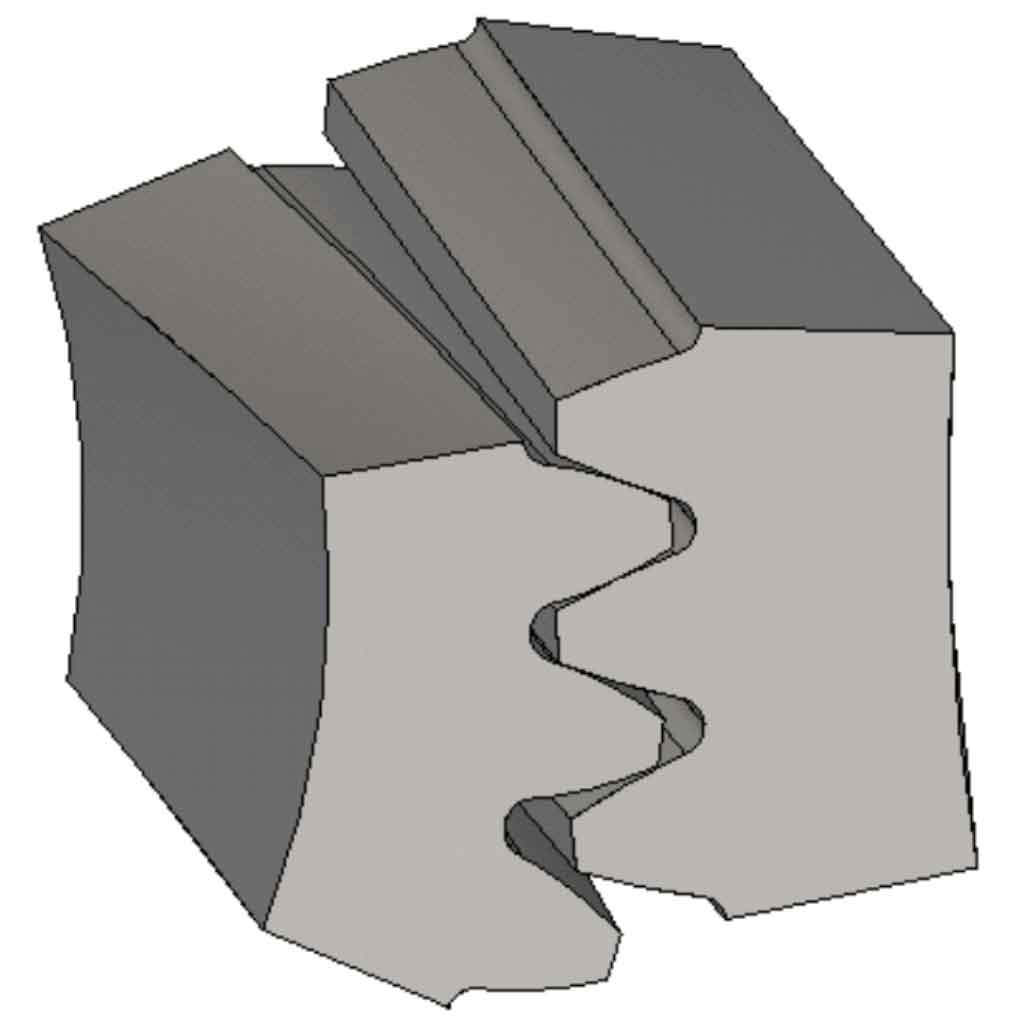

The contact problem of helical gears without tooth surface friction meets the above three assumptions and can be summarized as Hertz contact problem. In order to obtain a mesh control strategy in the contact area of helical gears that can be verified by the contact pressure and the half-width mesh independence of the contact zone, from simple to complex, the mesh independence verification process of a number of typical Hertz contact problems “two elastic cylinder normal contact” cases is studied first, and the general conclusion that “the mesh size threshold of the contact zone verified by the contact pressure and the half-width mesh independence of the contact zone is 1/4 times the half-width of the contact zone” is summarized, The conclusion is extended to the helical gear contact problem. The simulation example shows that the conclusion is valid in the helical gear simulation. Based on the conclusion, the meshing of the contact area of the helical gear can be solved to obtain reasonable contact pressure and half-width of the contact zone of the helical gear without grid independence verification, thus greatly improving the analysis efficiency of the helical gear contact simulation.