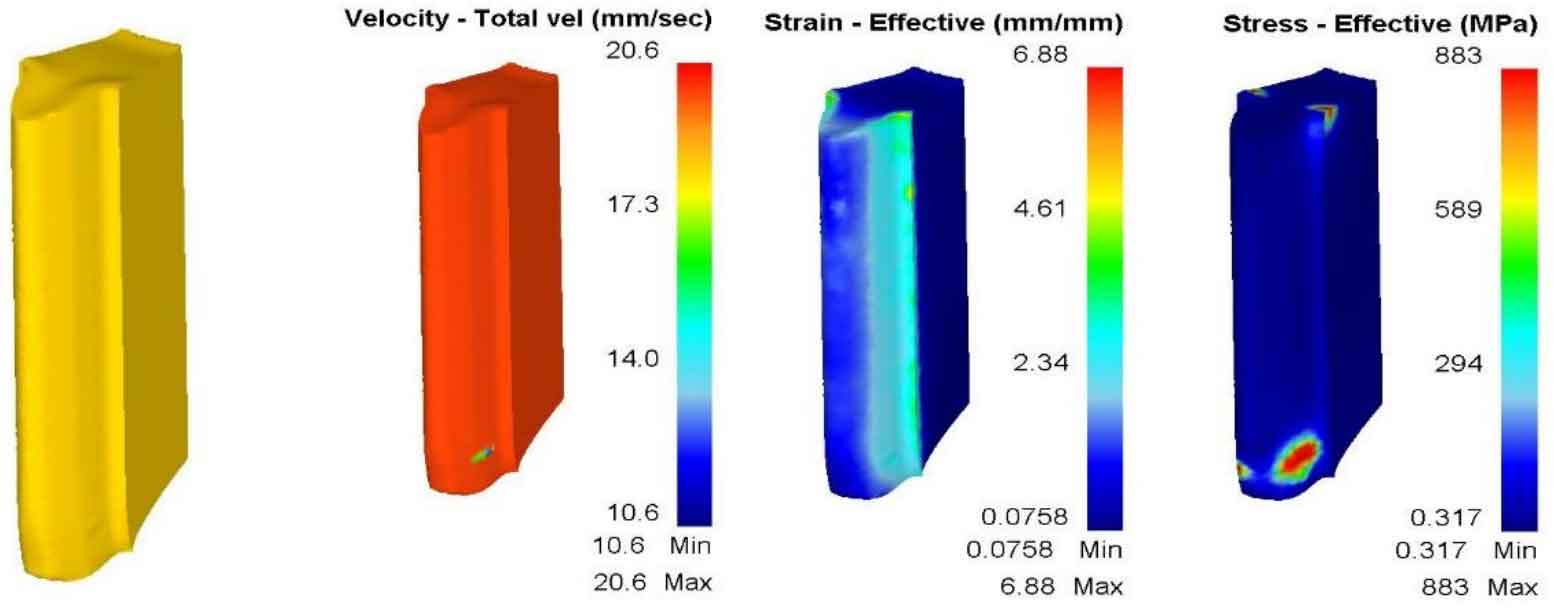

The continuous extrusion forming process of the external teeth of the spur gear is the same as that described above. The blank of the external teeth formed by continuous extrusion is put into the tooth profile guide sleeve of the finishing die. The end of the external teeth of the spur gear is in contact with the finishing die opening, and the circular simple flat punch with an outer diameter less than the diameter of the tooth top circle of the die moves down until it is in contact with the blank, The flat punch drives the whole blank to move downward into the die finishing area, and the metal flow rate on the corresponding tooth surface is relatively slow and small plastic deformation occurs. Figure 1 shows the initial finishing state when finishing the external teeth of spur gear alone.

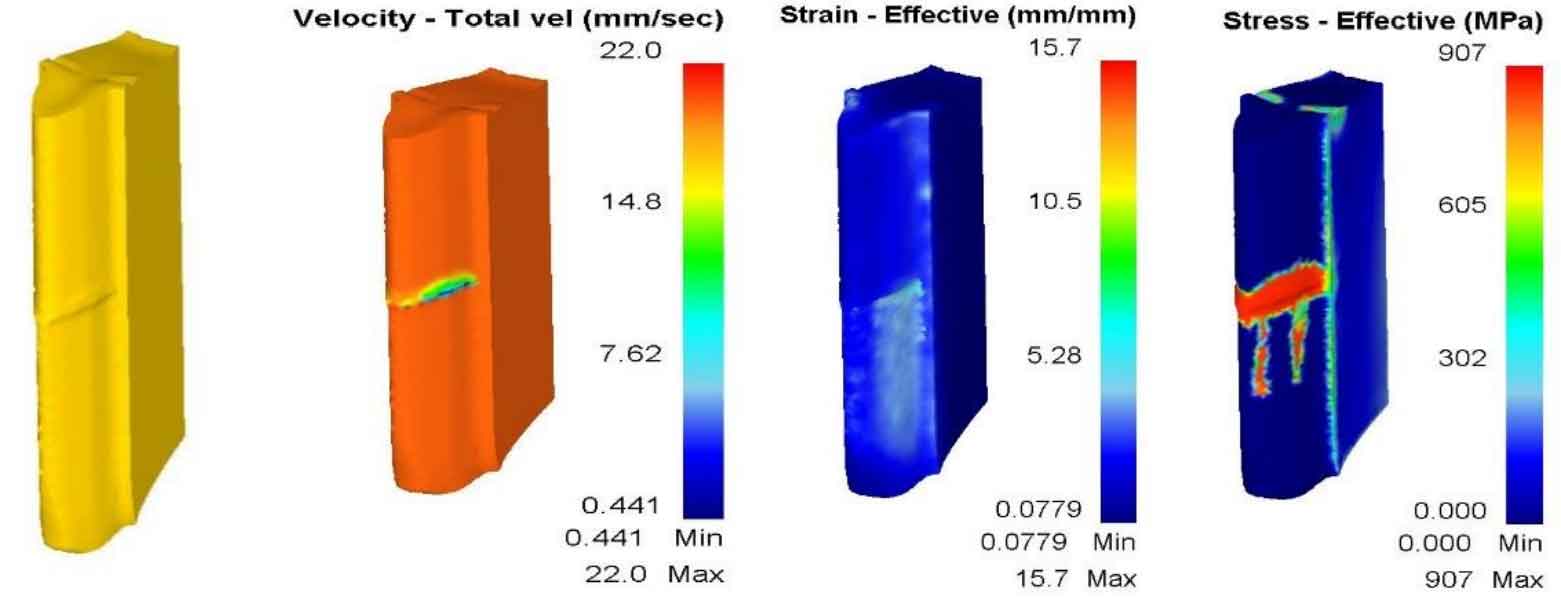

The flat punch pushes the blank downward and enters the stable finishing stage. The metal on the tooth surface of spur gear produces small plastic deformation. The flow speed of the metal on the tooth surface of spur gear is obviously less than that of the whole part, and the metal accumulates at the die inlet of the finishing die. Figure 2 shows the stable finishing state when finishing the external teeth of spur gear alone.

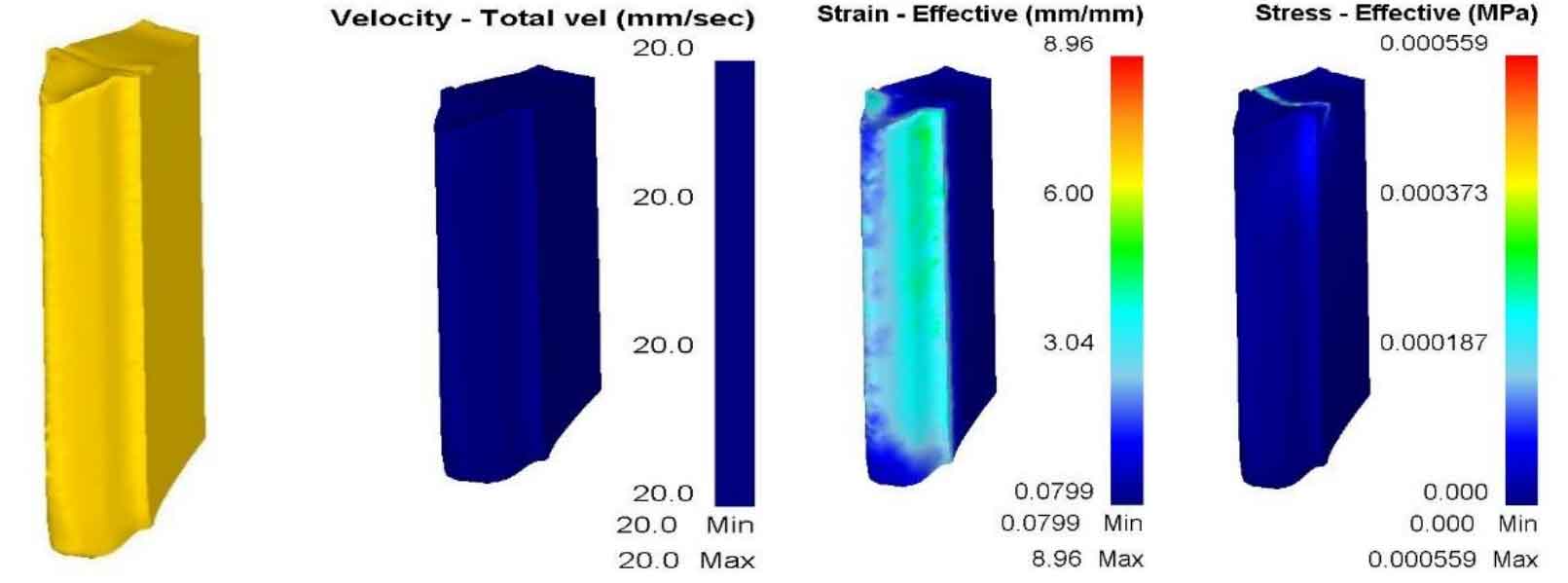

The flat punch pushes the blank to finish through the shaping area of the finishing die and falls from the through finishing die. During finishing, the metal on the tooth surface of spur gear will accumulate at the die opening of the finishing die, and finally form longitudinal burrs at the end of the blank. Figure 3 shows the finishing completion state when finishing the external teeth of spur gear alone.