The 45 steel gear blank is directly roughened into a column shape with an outer diameter of φ 78mm after blanking of φ 80mm round steel. Its chemical composition is: C: 0.49%, Mn: 0.68%, Cr < 0.2%. Heat treatment process: heat up in x-45 box type electric furnace and load it at the temperature of 820 ℃. The load is 109. The holding time is one hour (calculated time after the workpiece reaches the temperature). The workpiece is cooled by brine (the coolant is not circulating), and the water temperature is 20 ~ 30 ℃. The tempering temperature is 520-530 ℃ (tempering the parts every other day after quenching). After turning, it is found that there are many cracks on the inner hole plane and inner hole of the part.

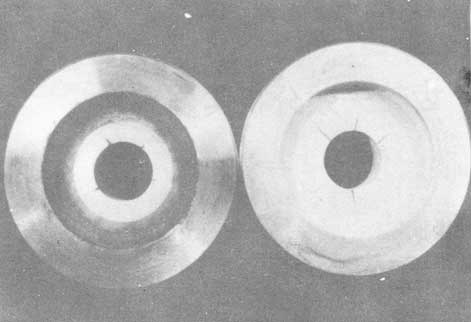

The macroscopic appearance of the parts was examined by sm-3r penetrant. Through the visual inspection and the magnifying glass observation, there are 5 ~ 6 long cracks in the surface of the inner hole and the inner hole of the gear blank, which are approximately the same distance. The cracks start from the interface of the inner hole and the hole and expand to the inner hole wall and the plane respectively; the processing lines on the surface of the inner hole and the interface of the inner hole are obvious and sharp.

Through metallographic observation on the plane specimen of the inner hole, several cracks were found to be cross distributed, and the inner part of the cracks was filled with oxide wallet. The length of microcracks were 0.63mm, 0.29mm, 0.23mm and 0.19, respectively.