In the field of aerospace and other high-stakes applications, there exists a class of machinery designed for single-use operation under extreme loads. These disposable systems, such as those found in electromechanical actuators, often rely on compact and high-power-density transmission components. Among these, the strain wave gear, commonly known as a harmonic drive, is a critical element due to its high reduction ratio, compactness, and precision. However, in disposable applications, these strain wave gears operate under short-duration, high-load conditions where traditional fatigue failure modes are less relevant. Instead, the primary failure concern shifts to catastrophic failures like rim fracture in the flexible spline, directly linked to the degradation of meshing stiffness. This study focuses on the crack propagation behavior within the flexible spline of a disposable strain wave gear and its consequent impact on the system’s meshing stiffness. Understanding this relationship is paramount for developing robust design theories and failure prediction methods for disposable strain wave gear systems.

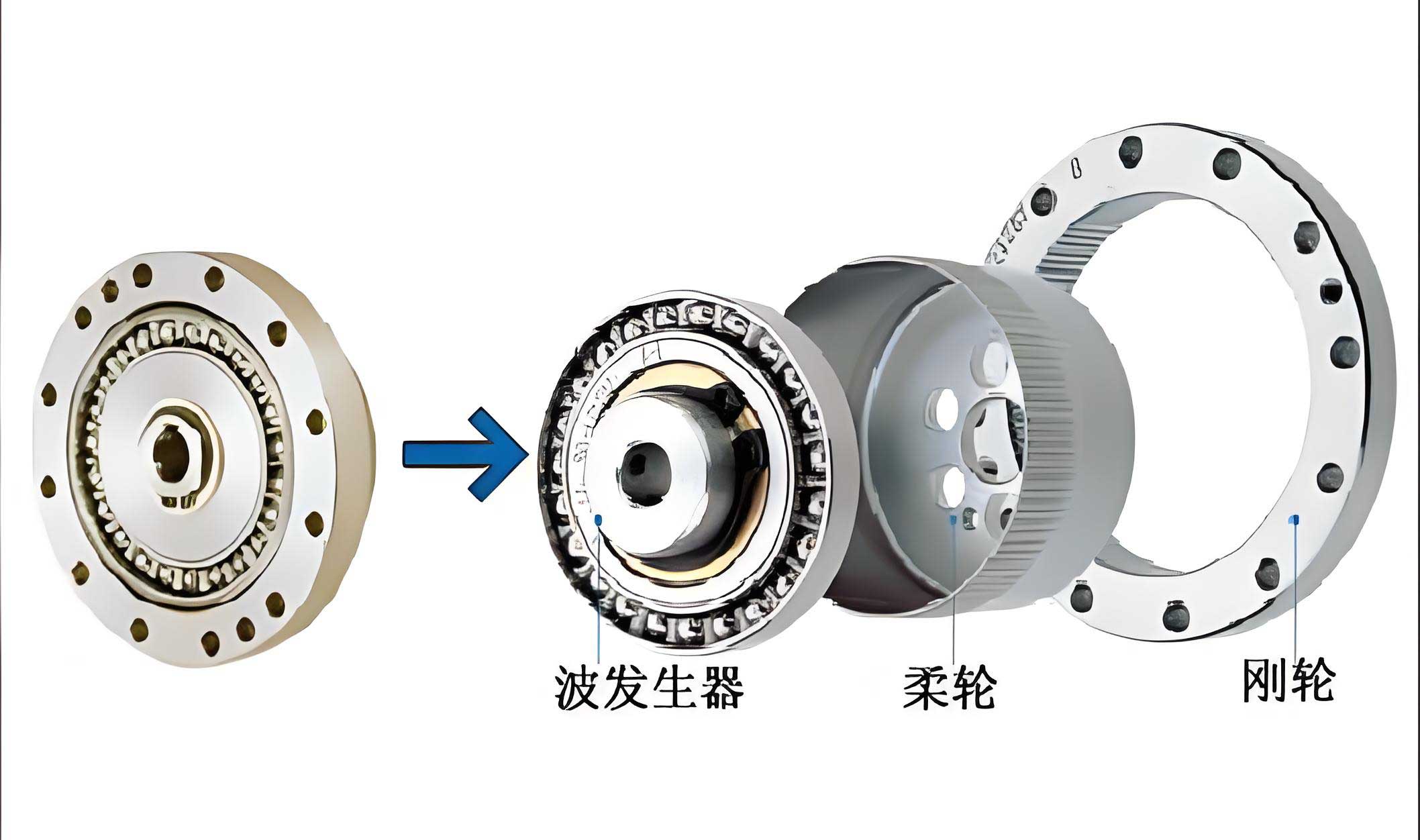

The core of a strain wave gear system consists of three parts: a rigid circular spline, a flexible spline, and a wave generator. The wave generator, often an elliptical cam, deforms the flexible spline, causing it to mesh with the rigid spline at two diametrically opposite regions. This unique operating principle allows for high reduction ratios in a compact package. For disposable applications, the design of the flexible spline is often simplified to a straight-walled cylinder to maximize power-to-weight ratio, contrasting with the traditional cup-shaped design used for long-life applications. This straight-walled disposable strain wave gear is essentially a thin-rimmed external gear, which is highly susceptible to stress concentration and crack initiation under the high loads typical of single-use scenarios.

The failure of a disposable strain wave gear is predominantly governed by fracture mechanics. Cracks typically initiate at points of high stress concentration, which for the flexible spline is the tooth root fillet region. To analyze this, we turn to Linear Elastic Fracture Mechanics (LEFM). Cracks are classified into three fundamental modes based on the loading conditions at the crack tip: Mode I (opening), Mode II (sliding or in-plane shear), and Mode III (tearing or out-of-plane shear). For the planar stress state assumed in a gear tooth model, the crack at the tooth root is generally a mixed-mode (I+II) crack, as it experiences both normal and shear stresses.

The stress field near the tip of a mixed-mode crack can be described by the stress intensity factors, \(K_I\) and \(K_{II}\). In polar coordinates \((r, \theta)\) centered at the crack tip, the stress components are given by:

$$

\sigma_{\theta\theta} = \frac{1}{\sqrt{2\pi r}} \cos\frac{\theta}{2} \left[ K_I \cos^2\frac{\theta}{2} – \frac{3}{2} K_{II} \sin\theta \right]

$$

$$

\tau_{r\theta} = \frac{1}{\sqrt{2\pi r}} \cos\frac{\theta}{2} \left[ K_I \sin\theta + K_{II} (3\cos\theta – 1) \right]

$$

where \(r\) is the radial distance from the crack tip and \(\theta\) is the angle from the crack plane. The direction of crack propagation, \(\theta_0\), is predicted by the Maximum Circumferential Tensile Stress (MCTS) criterion. This criterion states that the crack will propagate in the direction where the circumferential stress \(\sigma_{\theta\theta}\) is maximum, and propagation occurs when this maximum stress reaches a critical material value. The propagation angle is found by solving:

$$

\frac{\partial \sigma_{\theta\theta}}{\partial \theta} = 0, \quad \frac{\partial^2 \sigma_{\theta\theta}}{\partial \theta^2} < 0

$$

This leads to the following implicit equation for \(\theta_0\):

$$

\theta_0 = 2 \arctan\left( \frac{1}{4}\left[ \frac{K_I}{K_{II}} \pm \sqrt{\left( \frac{K_I}{K_{II}} \right)^2 + 8} \right] \right)

$$

This theoretical framework forms the basis for simulating crack growth in the disposable strain wave gear’s flexible spline.

To simulate the crack propagation, a finite element model of the disposable strain wave gear was constructed. The model includes the three primary components: the flexible spline, the rigid spline, and the wave generator. Key geometric parameters for the specific disposable strain wave gear studied are summarized in the table below.

| Component | Parameter | Value |

|---|---|---|

| Flexible Spline | Number of Teeth, \(z_f\) | 200 |

| Module, \(m\) (mm) | 0.16 | |

| Pressure Angle, \(\alpha\) (°) | 20 | |

| Rigid Spline | Number of Teeth, \(z_r\) | 202 |

| System | Gear Ratio, \(i\) | 100 |

The materials were selected for high strength. The flexible spline was modeled using 40CrNiMoA alloy steel, while the rigid spline and wave generator were modeled as 45 steel. Their properties are listed in the following table.

| Material (Component) | Density, \(\rho\) (kg/m³) | Young’s Modulus, \(E\) (GPa) | Poisson’s Ratio, \(\nu\) |

|---|---|---|---|

| 40CrNiMoA (Flexible Spline) | 7850 | 211 | 0.30 |

| 45 Steel (Rigid Spline & Wave Generator) | 7870 | 209 | 0.27 |

The simulation was performed in two steps: assembly and loading. In the assembly step, the wave generator was moved radially to deform the flexible spline, and then the rigid spline was positioned to engage with it. Contact interactions were defined between the flexible spline’s inner surface and the wave generator, and between the tooth flanks of the flexible and rigid splines. In the loading step, the rigid spline was fixed, and a torque was applied to the flexible spline, ramping up linearly to a maximum value representative of the extreme operating conditions of a disposable strain wave gear.

Stress analysis from the finite element model confirmed that the highest stresses in the system occurred at the tooth root fillets of the flexible spline, identifying this as the most likely site for crack initiation in a disposable strain wave gear. To model the crack growth from this point, the Extended Finite Element Method (XFEM) was employed. XFEM is particularly suited for this task as it allows for the modeling of discontinuous features like cracks without requiring the mesh to conform to the crack geometry, enabling efficient simulation of crack propagation.

Two main investigation paths were followed using XFEM: one with pre-defined initial cracks at the tooth root, and another without any pre-defined crack, allowing the crack to initiate based on the stress field. For the cases with pre-cracks, parameters such as initial crack location (\(\vartheta\), angle from the tooth centerline), orientation (\(\alpha\), angle from the tooth profile normal), and length (\(l_c\)) were varied. The table below shows a subset of the parameters used to study their influence on the crack path in the disposable strain wave gear’s flexible spline.

| Case | Location, \(\vartheta\) (°) | Orientation, \(\alpha\) (°) | Length, \(l_c\) (mm) |

|---|---|---|---|

| 1 | 5 | 10 | 0.01 |

| 2 | 10 | 30 | 0.02 |

| 3 | 15 | 50 | 0.03 |

| 4 | 20 | 70 | 0.04 |

| 5 | 25 | 90 (Normal) | 0.05 |

The simulation results revealed critical insights. The initial crack location \(\vartheta\) had the most pronounced effect on the propagation path. Cracks initiated closer to the tooth space center (\(\vartheta\) small) tended to propagate radially inward towards the flexible spline’s rim inner wall, leading to a complete rim fracture—the dominant failure mode for a disposable strain wave gear under high load. In contrast, the initial crack orientation \(\alpha\) and length \(l_c\) had a negligible impact on the overall propagation trajectory. In the simulation without a pre-crack, the crack naturally initiated at the tooth root near the space center and propagated inward, mirroring the path observed for a pre-crack with \(\vartheta = 5^\circ\). This confirms that rim fracture is the critical failure mechanism for this type of disposable strain wave gear.

Based on the observed crack path—approximately radial from the tooth root to the inner rim wall—a simplified analytical model for a cracked tooth in the disposable strain wave gear’s flexible spline was developed to quantify the effect on meshing stiffness. The tooth was modeled as a cantilever beam with a segment of reduced cross-section due to the crack. The total elastic energy \(U_\epsilon\) stored in a single cracked tooth under a meshing force \(F\) acting at an angle \(\theta_d\) (relative to the tooth centerline) can be derived using Castigliano’s theorem. The tooth is divided into three segments: the uncracked rim section (height \(h_\delta – l_c\)), the cracked rim section (height \(l_c\)), and the tooth section above the rim (height \(d\), where total tooth height \(h = h_\delta + d\)).

The energy is given by the sum of contributions from axial force, shear force, and bending moment in each segment:

$$

\begin{aligned}

U_\epsilon = & \int_{0}^{h_\delta – l_c} \frac{F_a^2}{2E A_{1p}} dx + \int_{0}^{h_\delta – l_c} \frac{F_b^2}{2G A_{1p}} dx + \int_{0}^{h_\delta – l_c} \frac{M_x^2}{2E I_{1p}} dx \\

+ & \int_{h_\delta – l_c}^{h_\delta} \frac{F_a^2}{2E A_{1pc}} dx + \int_{h_\delta – l_c}^{h_\delta} \frac{F_b^2}{2G A_{1pc}} dx + \int_{h_\delta – l_c}^{h_\delta} \frac{M_x^2}{2E I_{1pc}} dx \\

+ & \int_{h_\delta}^{h} \frac{F_a^2}{2E A_{1x}} dx + \int_{h_\delta}^{h} \frac{F_b^2}{2G A_{1x}} dx + \int_{h_\delta}^{h} \frac{M_x^2}{2E I_{1x}} dx

\end{aligned}

$$

Where:

– \(E, G\) are the Young’s and shear modulus of the flexible spline material (\(G = E/[2(1+\nu)]\)).

– \(F_a = F\sin\theta_d\), \(F_b = F\cos\theta_d\) are the axial and shear components of the meshing force.

– \(M_x = F[(h – x)\cos\theta_d – S_F \sin\theta_d]\) is the bending moment at distance \(x\) from the rim root, with \(S_F\) being the half-tooth thickness at the force application point.

– \(A_{1p}, I_{1p}\) are the area and moment of inertia of the uncracked rim cross-section: \(A_{1p} = P L\), \(I_{1p} = \frac{1}{12} P^3 L\), where \(P\) is the circular pitch and \(L\) is the face width.

– \(A_{1pc}, I_{1pc}\) are for the cracked rim section: \(A_{1pc} = (S_c + P/2) L\), \(I_{1pc} = \frac{1}{12} (S_c + P/2)^3 L\), where \(S_c\) is the distance from the crack to the tooth centerline, determined from XFEM results.

– \(A_{1x}, I_{1x}\) are for the tooth section: \(A_{1x} = 2 S_x L\), \(I_{1x} = \frac{1}{12} (2S_x)^3 L\), with \(S_x\) being the half-tooth thickness at height \(x\).

The deflection \(\delta_\epsilon\) of the tooth under force \(F\) is obtained from \(\delta_\epsilon = \partial U_\epsilon / \partial F\), and the stiffness of that single tooth is \(k_{tooth} = F / \delta_\epsilon\). This leads to a comprehensive expression for the deflection:

$$

\begin{aligned}

\delta_\epsilon = & \frac{F \sin^2\theta_d}{E A_{1p}} (h_\delta – l_c) + \frac{F \cos^2\theta_d}{G A_{1p}} (h_\delta – l_c) + \frac{F}{2E I_{1p}} \int_{0}^{h_\delta – l_c} \left[ (h – x)\cos\theta_d – S_F \sin\theta_d \right]^2 dx \\

+ & \frac{F \sin^2\theta_d}{E A_{1pc}} l_c + \frac{F \cos^2\theta_d}{G A_{1pc}} l_c + \frac{F}{2E I_{1pc}} \int_{h_\delta – l_c}^{h_\delta} \left[ (h – x)\cos\theta_d – S_F \sin\theta_d \right]^2 dx \\

+ & \frac{F \sin^2\theta_d}{E L} \int_{h_\delta}^{h} \frac{dx}{S_x} + \frac{F \cos^2\theta_d}{G L} \int_{h_\delta}^{h} \frac{dx}{S_x} + \frac{2F}{3E L} \int_{h_\delta}^{h} \frac{\left[ (h – x)\cos\theta_d – S_F \sin\theta_d \right]^2}{S_x^3} dx

\end{aligned}

$$

From this model, it is evident that the primary parameters affecting the stiffness of a cracked tooth in a disposable strain wave gear are the crack length \(l_c\) and the effective reduced section parameter \(S_c\). Since \(S_c\) is relatively constant from the simulation results, the crack length becomes the dominant variable. Calculating the single-tooth stiffness for various crack lengths shows a significant reduction, especially near the pitch point where the load is highest in the meshing cycle.

However, a strain wave gear operates with multiple tooth pairs in simultaneous contact. Therefore, the total meshing stiffness \(K_{total}\) of the disposable strain wave gear system is the sum of the individual stiffnesses of all tooth pairs in the engagement region at any given instant:

$$

K_{total}(\phi) = \sum_{j=1}^{N(\phi)} k_j(\phi)

$$

where \(\phi\) is the angular position of the wave generator, \(N(\phi)\) is the number of tooth pairs in contact, and \(k_j(\phi)\) is the stiffness of the \(j\)-th pair, which for a cracked tooth is given by the model above.

To quantify the system-level impact, the finite element model was used to extract the load and comprehensive elastic deformation for all contacting tooth pairs over a full engagement cycle, both for a healthy disposable strain wave gear and for one with an initial crack (\(l_c = 0.01 \text{ mm}, \vartheta=5^\circ\)). The results were used to compute the time-varying meshing stiffness. The stiffness curve for the healthy gear shows an initial rapid increase as teeth come into full contact, followed by a gradual decrease as they exit. The presence of a crack causes a noticeable reduction in stiffness throughout the engagement zone, with the most severe reduction occurring near the middle of the engagement zone where the load per tooth is maximal. This aligns perfectly with the analytical prediction that crack growth most severely affects the region of highest load.

The following table summarizes the calculated average meshing stiffness for the engagement zone under the two conditions, demonstrating the significant impact of even a small crack on the disposable strain wave gear’s load-bearing capacity.

| Condition | Average Meshing Stiffness in Engagement Zone (N/m) | Percentage Change |

|---|---|---|

| Healthy (No Crack) | \(K_{healthy}\) | Baseline (0%) |

| With Initial Crack (\(l_c=0.01mm\)) | \(K_{cracked}\) | Approx. -12% |

The analysis indicates that the presence of a crack at the tooth root of the flexible spline can reduce the overall meshing stiffness of the disposable strain wave gear by approximately 12%. This degradation is critical as it directly affects the torsional rigidity and positional accuracy of the transmission system, potentially leading to premature failure under the high dynamic loads characteristic of single-use applications.

In conclusion, this investigation into the behavior of disposable strain wave gears under high load has yielded several key findings. First, the crack propagation path in the flexible spline is predominantly influenced by the initial crack’s location relative to the tooth space center. Cracks initiating closer to this center propagate radially inward, leading to rim fracture—the primary failure mode for this class of strain wave gear. Second, under operational loads without pre-existing flaws, cracks naturally initiate at the tooth root near the space center and follow this inward path. Third, the development of these cracks directly and significantly degrades the meshing stiffness of the disposable strain wave gear system. The stiffness reduction is most pronounced in the heavily loaded central region of the meshing zone, and even a small initial crack can cause a measurable decrease (around 12%) in the system’s overall torsional stiffness. These insights provide a crucial theoretical foundation for fault diagnosis, remaining life prediction, and the design of more robust disposable strain wave gear systems intended for extreme, single-use missions. Future work could focus on probabilistic models for crack initiation under varying load spectra and the integration of this stiffness degradation model into dynamic system simulations for more comprehensive failure analysis of disposable strain wave gear drives.