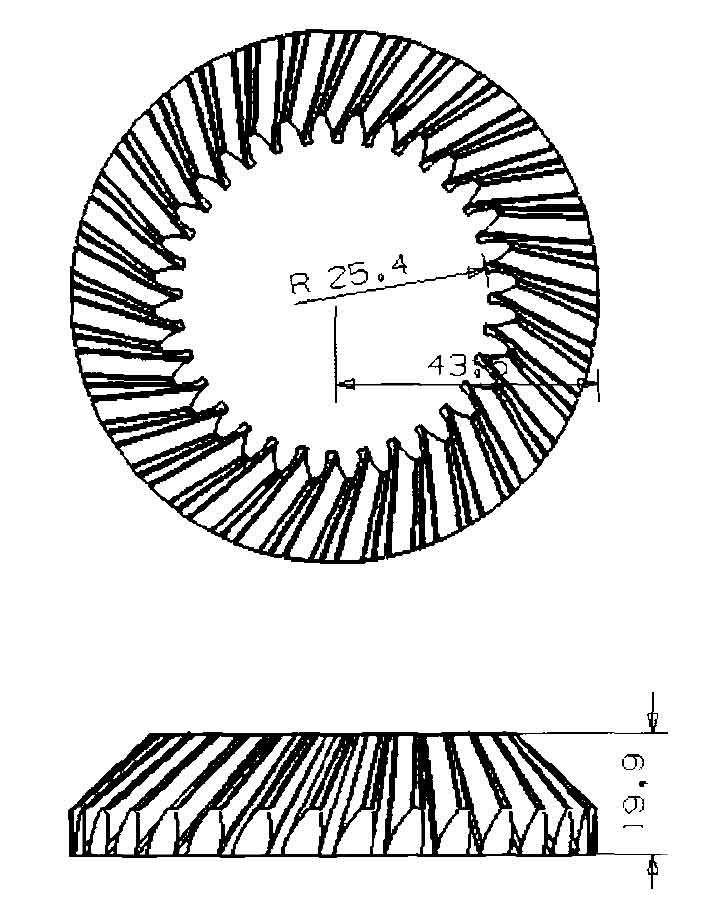

18CrNiMo7-6 belongs to low carbon and low alloy carburized steel. It is mainly used to manufacture bevel gears of wind power transmission, electric locomotives of heavy-duty trains, large modulus bevel gears, heavy-duty bevel gears and other parts. The bevel gear shaft is prone to cracking in the process of production and use. Zhang Zechun studied that the raw material of 18CrNiMo7-6 steel bevel gear shaft was mixed with molten steel in the smelting process; Brittle inclusions in the material destroy the continuity of the material, form gaps and stress concentration. Under the action of residual stress, the bevel gear shaft has delayed cracking. Zhou Jisheng studied that the specific reason for the cracking of the bevel gear of the reducer is that the effective hardened layer depth of the bevel gear exceeds the technical requirements, resulting in a large tensile stress in the center. The crack source is located in the center of the fracture, and there are many non-metallic inclusions composed of O, Al, CA, Na and other elements. These inclusions have high hardness and are easy to split the matrix of the material. When subjected to external force, they are easy to produce stress concentration to form the crack source. This paper studies and analyzes the macro morphology, composition and performance, and puts forward the solution according to the analysis and summary.

According to macro analysis, chemical analysis, crack morphology analysis and metallographic structure analysis, the following conclusions can be drawn.

1) On the premise of not touching the crack source, the chemical composition and beneficial elements of the failed bevel gear are controlled to be qualified; The residual gas content is well controlled; Through macro magnetic particle testing, no cracks were found on the shallow surface of bevel gear material; There is no inclusion and decarburization on both sides of the crack. It can be seen that the raw materials do not have cracking defects.

2) On the premise of not touching the crack source, the microstructure near the two cracks is relatively uniform, and the hardness basically meets the production process requirements through surface and internal section detection.

3) The original record shows that the information is consistent with the measured residual austenite. The residual austenite exceeds the standard seriously, which is easy to cause gear strength reduction, size out of tolerance or local microcracks.

Therefore, on the basis of multi-point local detection of cracks, it can be inferred that the raw materials have no crack causing defects. Due to the unstable structure, the retained austenite continues to change during tempering and placement. Too much retained austenite directly affects the compressive stress distribution on the surface of bevel gear. At the same time, in the production and processing process, there are misunderstandings in operation. Improper operation leads to the generation of crack source point, which exceeds the strength of the material itself. After being discharged from the furnace, it is released rapidly at the position of stress source point, resulting in instantaneous cracking in the area of structural stress concentration on the ring surface.

Finally, it is suggested that after carburizing and direct quenching, cold treatment should be added to reduce residual austenite; Standardize furnace production, and try to use carburized bevel gears with the same material grade and alloy coefficient in the same furnace; There are human factors causing the fracture of bevel gear, so it is necessary to correct the human operation and guide relevant personnel to produce correctly and comply with the process flow.