The shape of straight bevel gear is relatively complex, and its surface is basically composed of curves and curved surfaces. The general commercial software UG can accurately describe the finite element of straight bevel gear.

| Parameter name | Calculation formula | Calculation results |

| Graduation circle diameter | d=mz | 60.00 |

| Cone distance | R=d/2sinδ | 94.87 |

| Diameter of indexing circle at the midpoint of tooth width | dm=d-bsinδ | 53.68 |

| Mid point modulus of tooth width | mm=dm/z | 5.37 |

| Addendum height | hα=(hα*+x)m | 8.45 |

| Root height | hf=(hα*+c*-x)m | 4.75 |

| Full tooth height | h=(2hα*+c*)m | 13.20 |

| Diameter of large end addendum circle | dα=d+2hαcosδ | 76.04 |

| Large end indexing circular arc tooth thickness | s=m(π/2+2xtanα+xτ) | 11.91 |

| Large end indexing circle chord tooth thickness | s’=dsin(scosδ/d)/cosδ | 11.84 |

| Large end indexing circle chord tooth height | h’α=dα-dα cos(scosδ/d)/2cosδ | 9.02 |

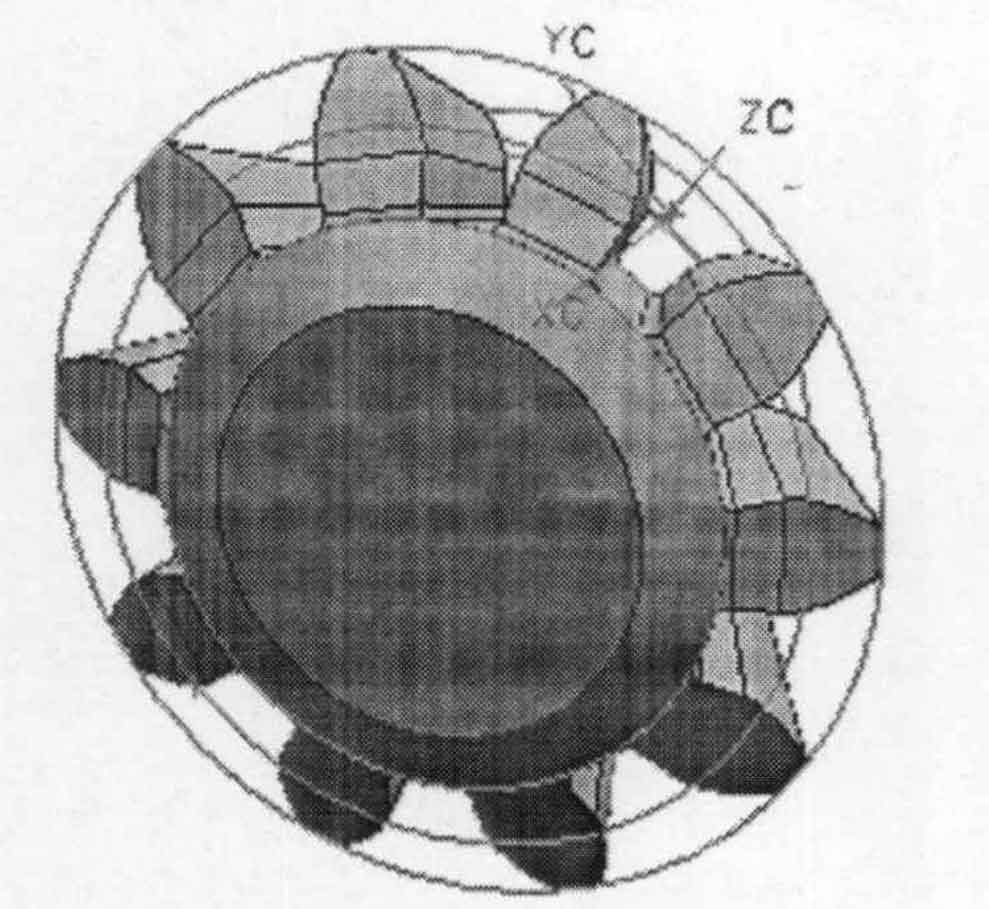

The forging drawing of straight bevel gear obtained through the process is shown in the figure. After modeling, save and save a part in IGES format at the same time, which is convenient for importing to Pro / E to generate mold model.