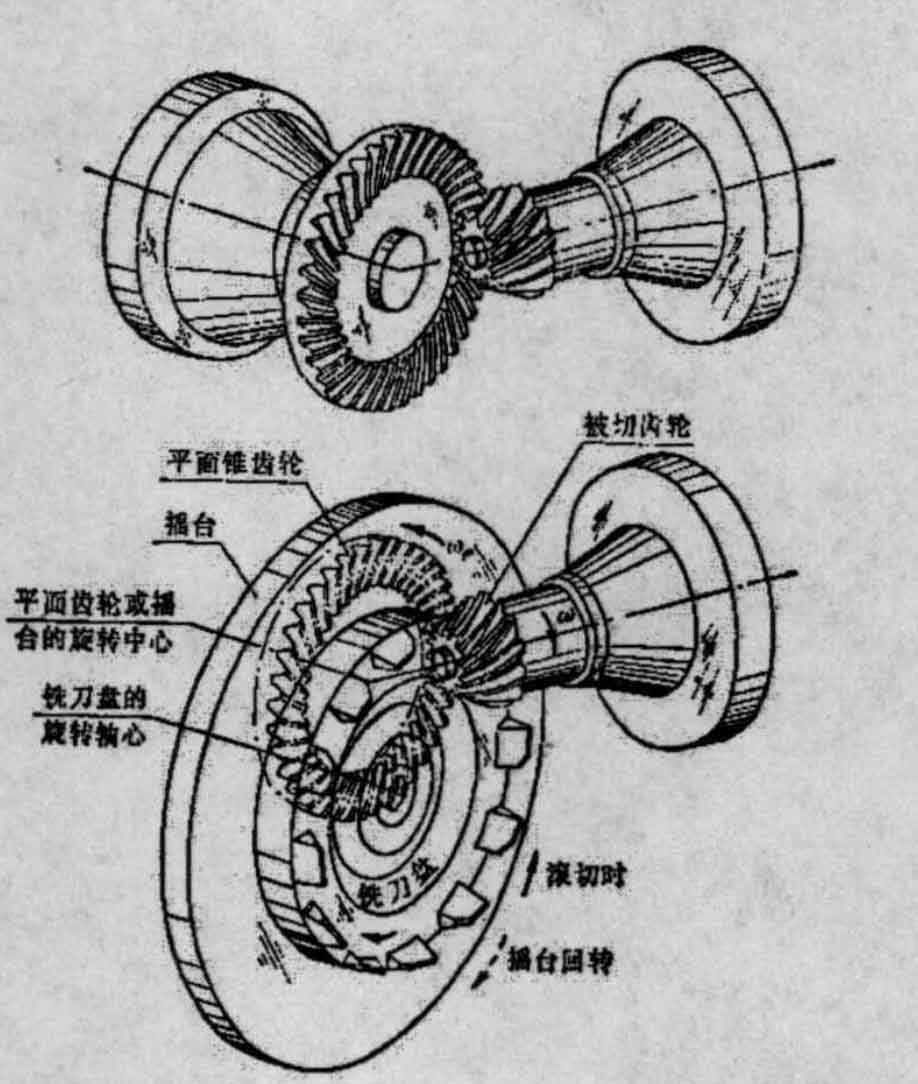

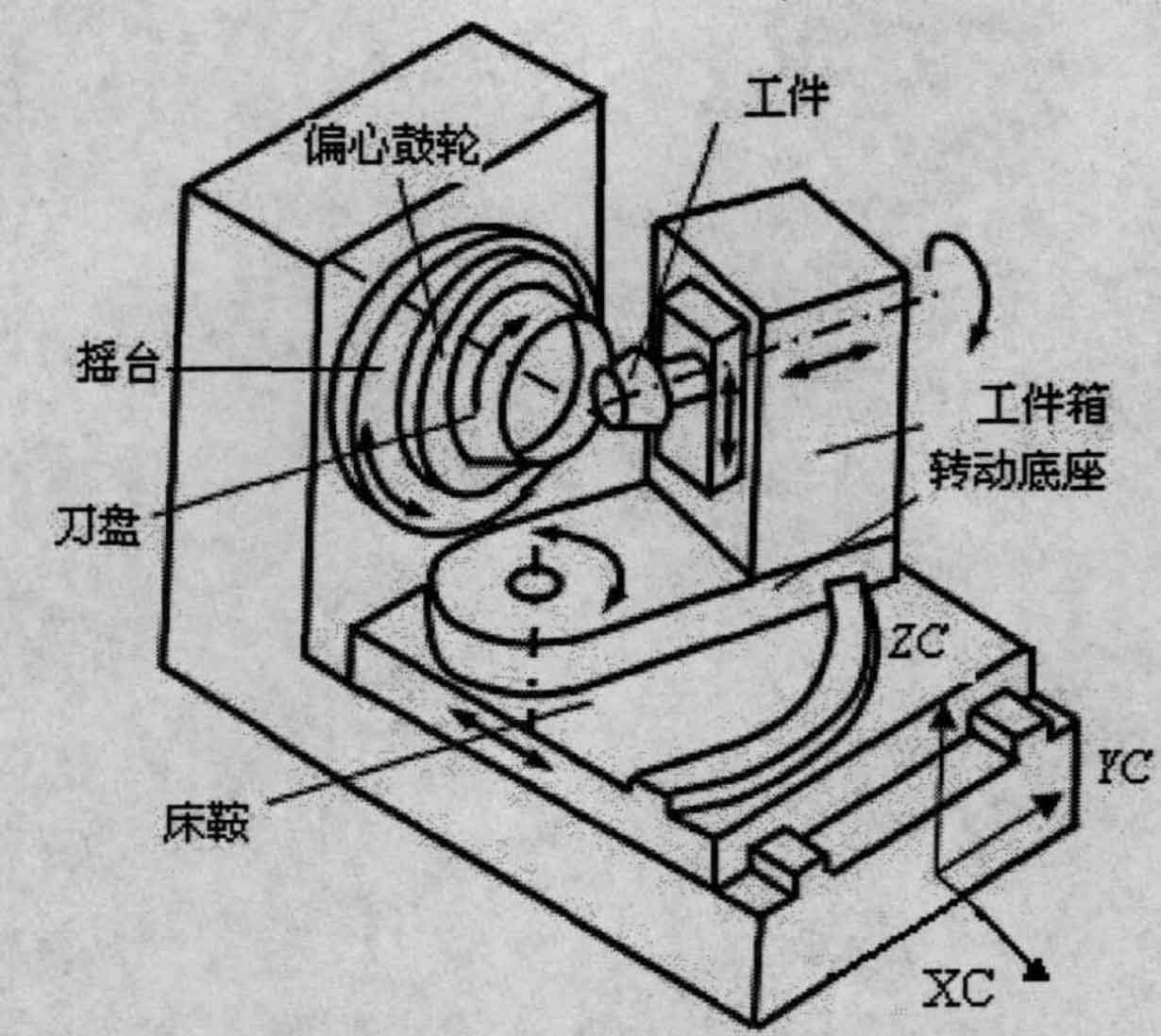

The hypoid gear of the micro car main reducer is processed on the hypoid gear milling machine. The processing principle of Gleason machine tool is shown in Figure 1. Y2250 and Y2280 machine tools are designed according to the principle of “imaginary flat top gear”. That is to say, in the process of gear tooth cutting, according to the principle of local co choke, it is assumed that there is a flat top gear concentric with the shaking table of the machine tool. During the rotation of the shaking table of the machine tool, it engages with the gear to be cut without clearance. This imaginary flat top gear is composed of the motion path of the tool. Through the relative movement between the two, during the rotation of the shaking table, the cutter gradually cuts the tooth groove on the wheel blank. It can be seen that the gear cutting process is like the meshing process of the hypoid gear, and the cutting surface of the milling cutter head and the tooth surface of the gear to be cut form a pair of completely conjugate curved surfaces. This processing method of hypoid gear is called generating method, and the imaginary gear represented by the shaking table is called generating wheel.

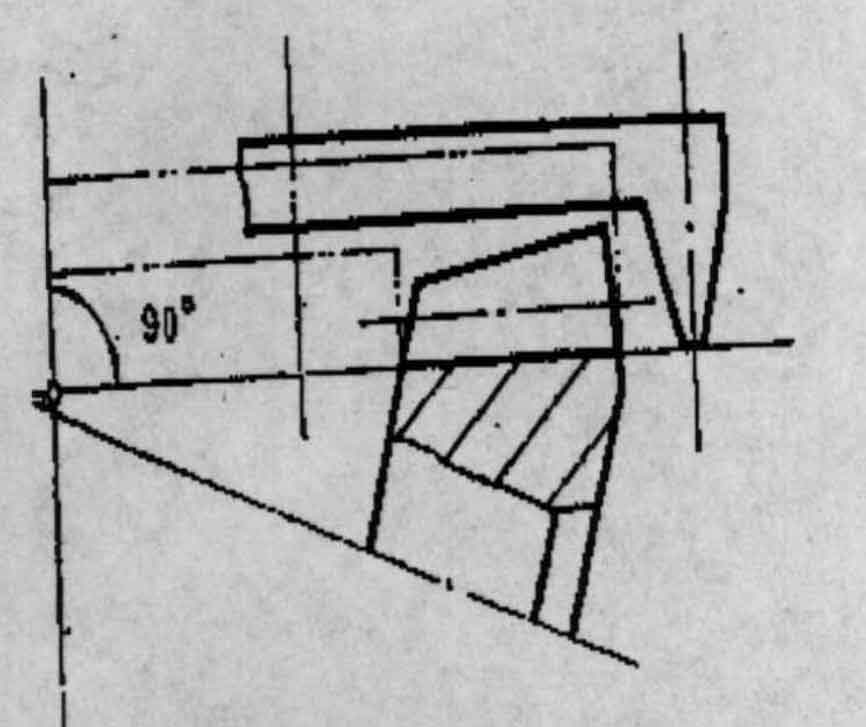

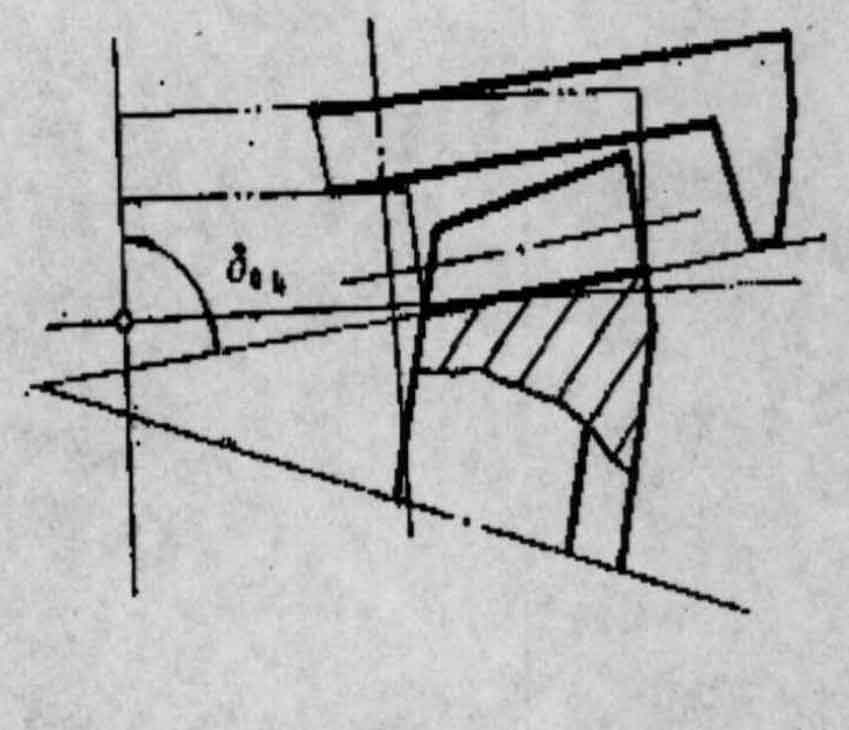

In the processing of hypoid gears, there are two kinds of generating wheels commonly used: plane generating wheel and conical generating wheel, as shown in Fig. 2 and Fig. 3 respectively. The central axis of the cutter head of the flat forming wheel is parallel to the central axis of the shaking table, and the surface cone angle of the forming wheel δ= 90 °, the cutter head axis of the conical forming wheel and the shaking table axis are not parallel, and the surface cone angle of the forming wheel δ Not equal to 90 °.

The driven wheel of the hypoid gear is generally processed by the plane forming wheel. In order to improve the processing efficiency, the driven wheel is processed by the double-sided method, and the inner cutting blade and the outer cutting blade are installed on the double-sided milling cutter disc, so that the entire tooth profile can be cut at the same time, and then fed to the next station for cutting, and the entire hypoid gear can be processed step by step. When the pitch cone angle of the driven wheel δ When the angle is less than 70 °, the driven wheel must be processed by generating method. When the pitch cone angle of the driven wheel δ When it is greater than 70 °, the shape of the driven gear tooth surface processed by the generating method is similar to that of the cutter head, and the root cone of the driven wheel is close to the center tangent plane of the root cone. Thus, the driven wheel can be processed without the generating method, and the milling cutter head can directly cut into the wheel blank, that is, the forming method is adopted. This can greatly improve the production efficiency and is suitable for the production of large-scale hypoid gears. At the same time, when the forming method is used, the structure of the machine tool can be greatly simplified, which is more suitable for mass production.

The driving wheel of hypoid gear can be processed by either conical or plane generating wheel. For example, when the conical forming wheel is used, the transmission ratio between the forming wheel and the workpiece is constant, and it can only be processed on the machine tool with the tool tilting mechanism. This processing method is called the tool tilting method. The cutter tilt method requires very low tooth profile angle of the cutter head for machining the driving wheel. The error between the tooth profile angle of the cutter head and the pressure angle of the driving wheel pitch can be compensated by the cutter tilt mechanism. It is convenient to adjust the machining. When the planar generating wheel is used, the transmission ratio of the generating wheel and the workpiece is changed. This machining method must be processed on the machine tool equipped with the denaturing mechanism. Therefore, this machining method is called the denaturing method. Regardless of the tool inclination method or the denaturing method, the tooth profile angle of the driving wheel cutter head has no special strict requirements and can be selected from the standard values. However, the difference between the tooth profile angle of the driven wheel cutter head of the denaturing method and the theoretical value shall not exceed 1.5 degrees.

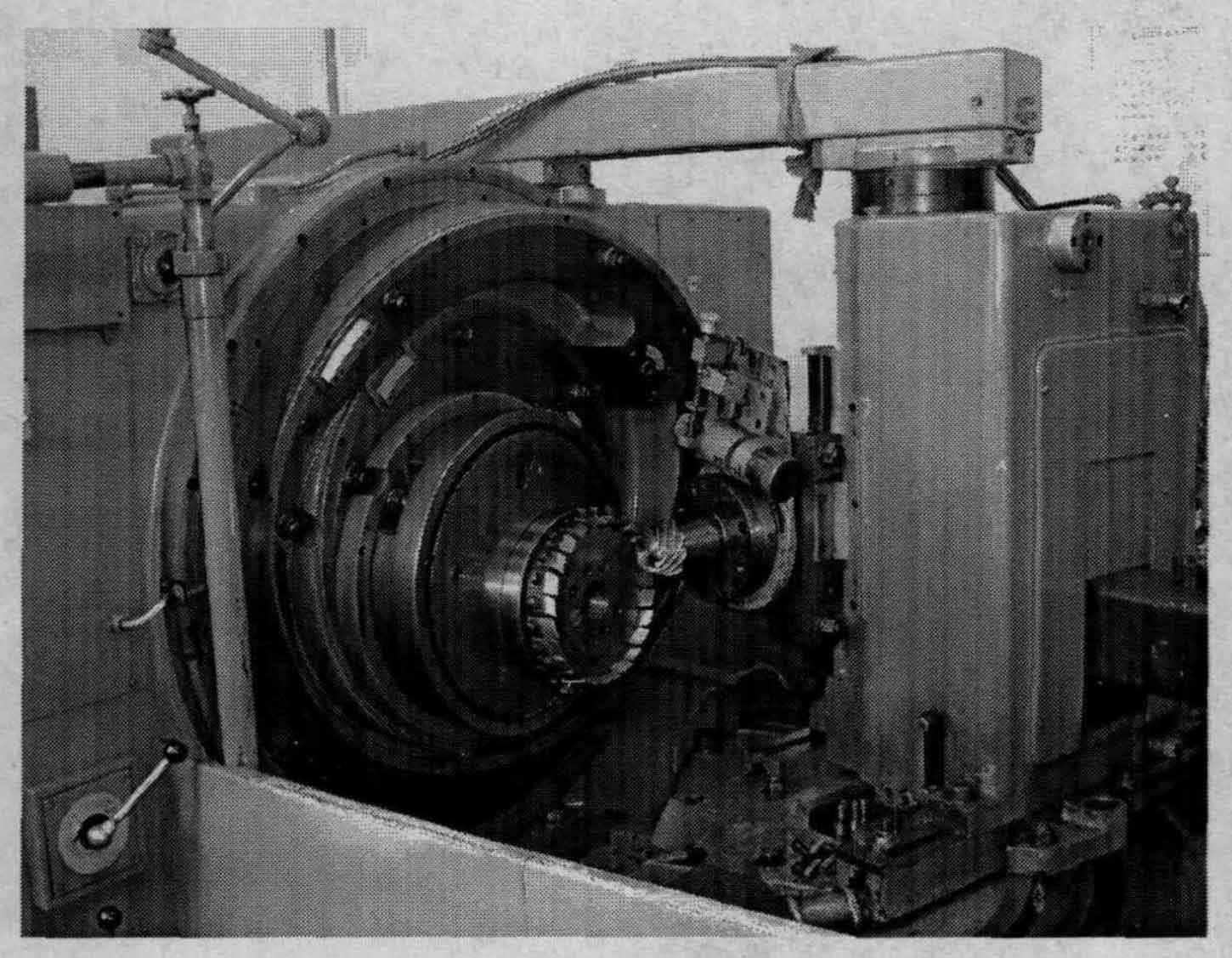

The hypoid gear of the main reducer of the micro car is processed on the Gleason gear milling machine. During the processing, it should be continuously cooled to avoid damage to the tool and workpiece due to high temperature. The coolant is generally lubricating oil with low viscosity. The processing process of Gleason machine tool is shown in Figure 4.

The structure of the machine tool is simplified, and the simplified model of the machine tool is constructed as shown in Fig. 5. The tooth ratio of the hypoid gear of the rear axle main reducer is 8 / 41. For this hypoid gear, according to its design and technical requirements δ When the angle is greater than 70 °, the forming method is adopted for processing, while the cutter inclination method is adopted for processing the driving wheel to improve the production efficiency.