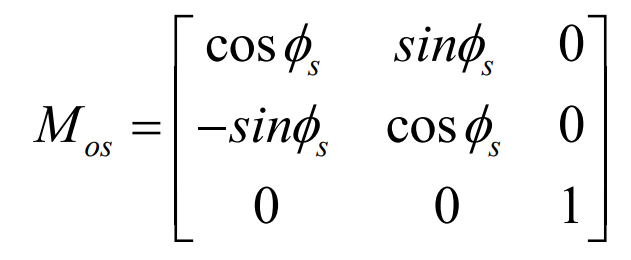

Bevel gear turning gear is a continuous generation method based on the meshing principle of spatial staggered shaft gear. When the tool and workpiece rotate in a fixed proportion, the relative speed of the tool and workpiece at the cutting point is generated. Because the relative speed is not equal to zero, it is possible to turn bevel gears. The cutting speed of the bevel gear turning tool at the cutting point can be obtained by using the bevel gear turning coordinate system. The relative speed is the difference between the tool speed and the workpiece speed. The solution of relative speed needs to be applied to the relative position vector term between the two coordinate systems of tool and workpiece. According to the formula, the relative position vector term is as follows:

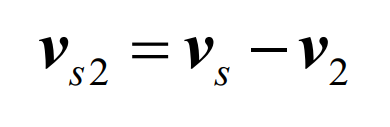

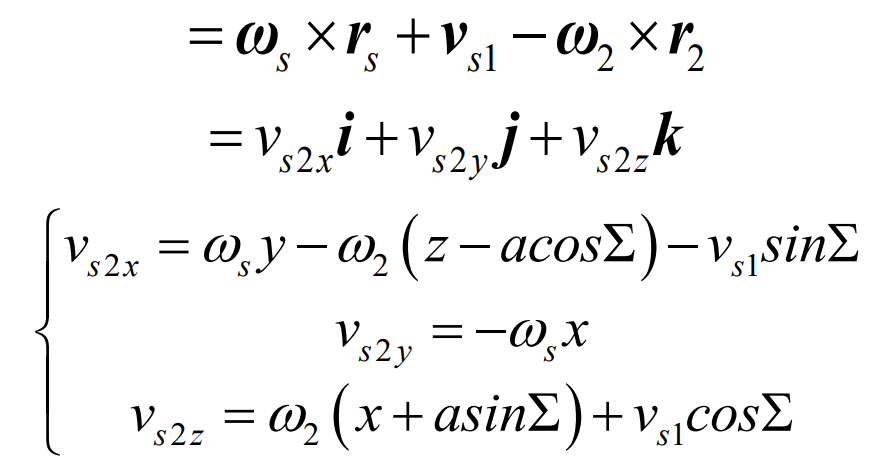

As long as the position vector and angular velocity of the tool and workpiece are known, the relative velocity can be obtained. The relative speed 2 can be expressed as:

In the above formula, and 2 represent the angular speed of the tool and the workpiece respectively, 1 represents the feed speed of the tool, represents the angle between the tool and the workpiece, represents the coordinate value of the cutting point in the coordinate system , and the relative speed2 is also based on the coordinate system.