To measure the standard of qualified spiral bevel gear blank, in addition to achieving the shape and dimensional accuracy, the formation of defects will also become the key factor for the scrapping of spiral bevel gear blank. Therefore, the defect analysis of formed spiral bevel gear blank is also particularly important.

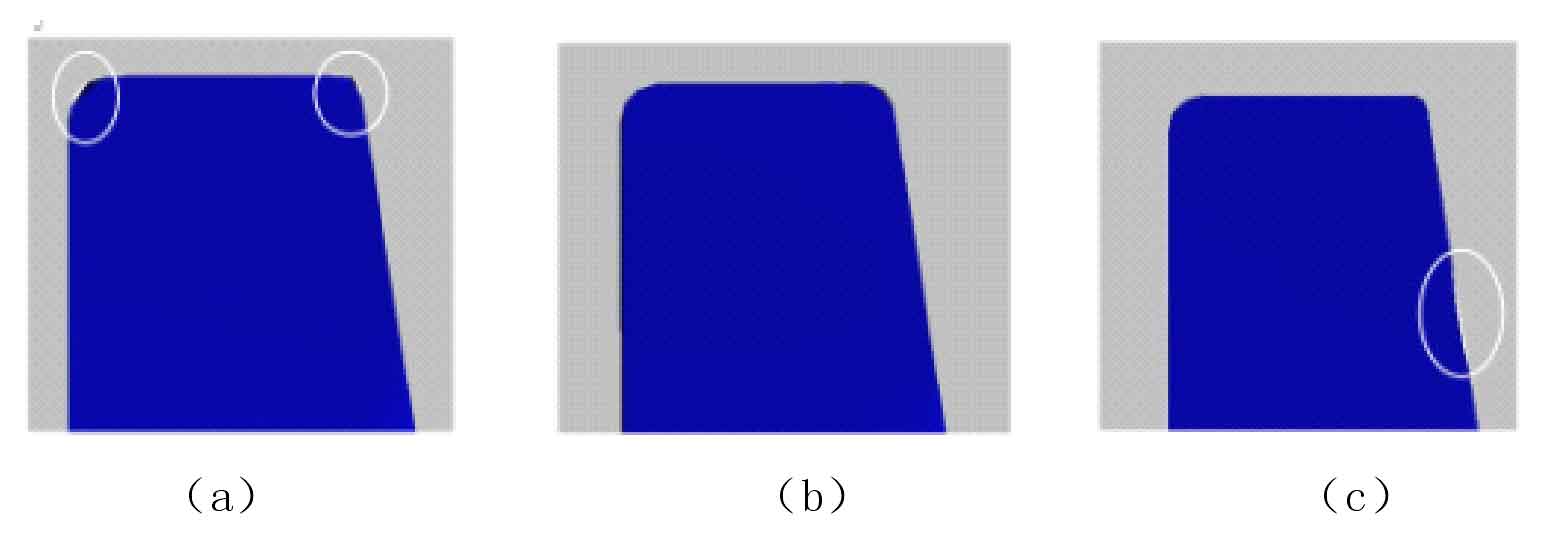

The figure shows the cross-sectional view of the formed spiral bevel gear blank. Figures a ~ C in the figure respectively show the cross-sectional view of the formed spiral bevel gear blank in schemes 1 to 3. In figure a, the forming die is not fully filled, and there is a gap at the fillet. C there is a gap at the end face slope of the ring in the figure, resulting in the so-called “fishtail” phenomenon. B the material in the figure completely fills the cavity and forms

Good quality.

Through the analysis and comparison of the above spiral bevel gear blank forming simulation results, it is finally concluded that only the ring blank of scheme 2 can form the spiral bevel gear blank with good forming effect and high quality and precision. Therefore, the size of scheme 2 is selected as the ring blank size of the final spiral bevel gear blank.