The deformation of gear heat treatment is very complex, which is a comprehensive reflection of the factors affecting the deformation of all cold and hot machining processes. Such as mechanical residual stress, thermal stress and structural stress in quenching process, carburized layer depth (or effective hardened layer depth), material hardenability, cooling rate of quenching medium, pre heat treatment and charging mode. It is difficult to take measures only from the aspect of heat treatment to solve the gear deformation. Considering various factors in the whole process of cold and hot processing, according to the specific situation, specific analysis, taking corresponding measures, comprehensive treatment, eliminating or reducing the influence degree of adverse factors, is an effective method to reduce the deformation of gear heat treatment.

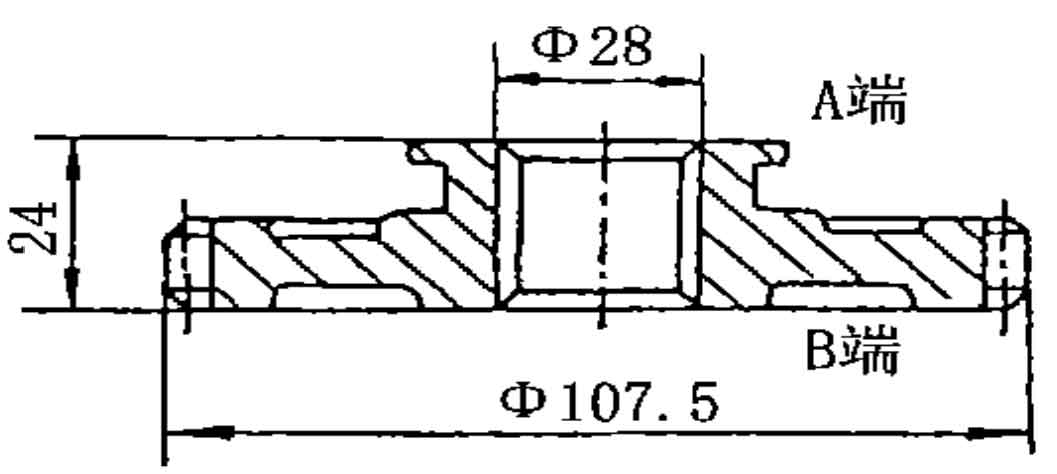

The experimental study on spline hole deformation of reverse sliding gear of small tractor (see Figure) is introduced. The results show that the depth of carburized layer and cooling rate of quenching medium are the main factors to control the heat treatment deformation of carburized gear. Reducing the depth of carburized layer, cooling rate of quenching medium, manufacturing gear with carburized carbon steel to ensure hardenability and close cooperation between cold and hot processing are important ways to reduce the shrinkage of carburized gear.

The research on Carburizing and carbonitriding of automobile gears shows that metallurgical adjustment is very important in the process of heat treatment. Using steel with narrow hardenability band, properly adjusting the depth of carburized layer and reducing the amount of residual austenite can not only make the deformation of parts small and regular, but also make the carburized layer obtain the best residual compressive stress distribution, so as to obtain the maximum fatigue life.