In the field of precision motion control and robotics, the demand for compact, high-torque, and high-accuracy transmission systems has led to the widespread adoption of strain wave gear reducers, commonly known as harmonic drives. I have been extensively involved in the research and development of these devices, focusing particularly on tooth profile optimization to enhance performance. The double circular arc tooth profile represents a significant advancement over traditional profiles, such as the involute, due to its superior characteristics in minimizing stress concentration, avoiding tooth interference, and facilitating lubricant film formation. This article delves into the detailed design methodology for both the flexspline and circular spline of a strain wave gear reducer utilizing a double circular arc profile. The process integrates kinematic harmonic meshing theory with numerical computation, specifically using MATLAB for solving conjugate tooth profiles and performing curve fitting. The goal is to provide a comprehensive guide that underscores the analytical and practical steps involved, emphasizing the repeated application and benefits of the strain wave gear mechanism.

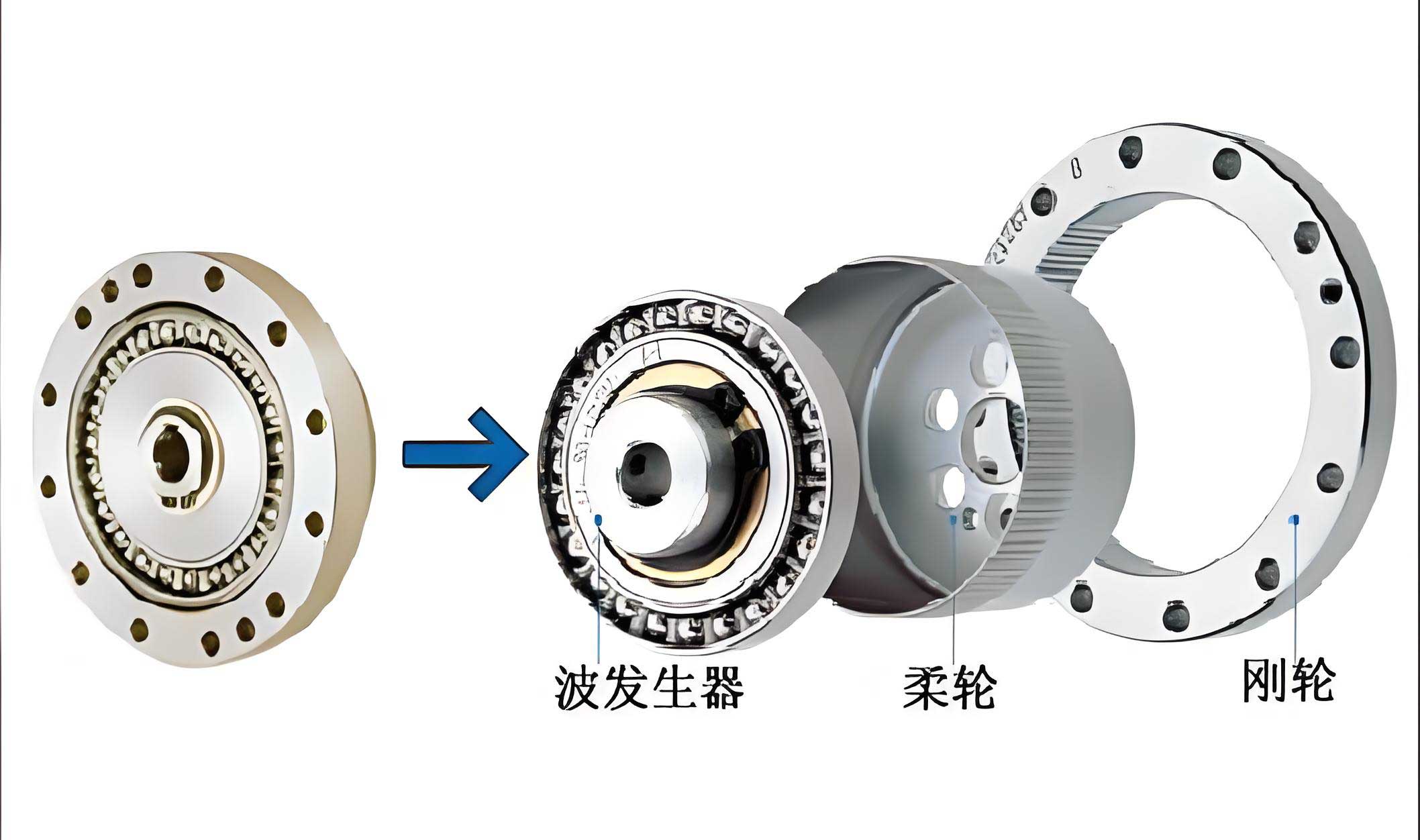

The fundamental operation of a strain wave gear relies on the elastic deformation of a flexible component, the flexspline, by a wave generator, enabling meshing with a rigid circular spline. This unique principle allows for high reduction ratios, zero-backlash operation, and compact design. However, the tooth profile plays a critical role in determining the load distribution, efficiency, and longevity of the strain wave gear. The double circular arc profile, comprising convex and concave arcs, increases the number of simultaneously engaged tooth pairs, improves load-sharing, and reduces the risk of edge contact and pitting. In my design approach, I prioritize a systematic parameter selection for the flexspline, followed by a rigorous derivation of the conjugate circular spline profile through coordinate transformation and envelope theory.

To initiate the design, I define the primary specifications for the strain wave gear reducer. For instance, consider a reducer with a transmission ratio of \( i = 80 \), a module of \( m = 0.3 \, \text{mm} \), and an input torque of \( 72 \, \text{N·m} \). The number of teeth on the flexspline \( Z_1 \) and the circular spline \( Z_2 \) are derived from the reduction ratio formula for strain wave gears:

$$ i = \frac{Z_2}{Z_2 – Z_1} $$

Given \( i = 80 \), and selecting \( Z_2 – Z_1 = 2 \) (typical for many strain wave gear designs), we obtain:

$$ Z_1 = 160, \quad Z_2 = 162 $$

These values ensure the necessary differential motion inherent to the strain wave gear operation.

Flexspline Tooth Profile Design

The flexspline, being the deformable element, requires careful consideration of its tooth dimensions to withstand cyclic stress while maintaining precise meshing. The double circular arc profile for the flexspline is characterized by several key parameters: tooth height, pressure angle, arc radii, and their relative positions. Unlike standard gears, the working depth of engagement in a strain wave gear differs from the total tooth height due to the radial deformation induced by the wave generator.

The theoretical full tooth height \( h \) is often taken as twice the module, similar to standard gears, but the actual meshing depth \( h_{d1} \) is typically between \( 1.2m \) and \( 1.3m \). To provide clearance and enhance bending strength at the root, the flexspline’s total tooth height can vary within \( (1.8 \sim 2.2)m \). I allocate the addendum \( h_a \) and dedendum \( h_f \) asymmetrically:

$$ h_a = (0.7 \sim 1.0)m, \quad h_f = (1.1 \sim 1.5)m $$

The tip clearance \( C_a \) is set between \( (0.2 \sim 0.35)m \). For the pressure angle \( \alpha_0 \), a value of \( 25^\circ \) is commonly adopted in strain wave gear designs to balance force transmission and tooth strength.

The double circular arc profile consists of a convex arc near the addendum and a concave arc near the dedendum. The radii of these arcs, \( \rho_a \) and \( \rho_f \), along with their difference \( \Delta\rho = \rho_a – \rho_f \), influence the sensitivity and running-in behavior of the strain wave gear. For small-module gears with softer tooth surfaces, the radius difference is often approximated as:

$$ \Delta\rho \approx 0.1 \rho_a $$

This prevents excessive sensitivity to manufacturing errors while ensuring proper engagement. The convex arc radius \( \rho_a \) is typically chosen in the range \( (1.15 \sim 1.5)m \) to optimize contact and bending stresses. Another critical parameter is the tooth thickness ratio \( K \), defined as the ratio of space width to tooth thickness at the pitch circle:

$$ K = \frac{S_f}{S_a} $$

where \( S_f \) is the space width and \( S_a \) is the tooth thickness. Values between 1.1 and 1.3 are recommended for improved bending strength in double circular arc strain wave gears.

Based on these guidelines, I establish the specific parameters for the flexspline of our example strain wave gear reducer. The selections are summarized in the following table:

| Parameter Name | Symbol | General Relationship | Selected Value (mm) |

|---|---|---|---|

| Module | \( m \) | – | 0.3 |

| Transmission Ratio | \( i \) | – | 80 |

| Full Tooth Height | \( h \) | \( 2m \) | 0.6 |

| Addendum | \( h_a \) | \( (0.7 \sim 1.0)m \) | 0.24 |

| Dedendum | \( h_f \) | \( (1.1 \sim 1.5)m \) | 0.36 |

| Tip Clearance | \( C_a \) | \( (0.2 \sim 0.35)m \) | 0.06 |

| Pressure Angle | \( \alpha_0 \) | – | \( 25^\circ \) |

| Convex Arc Radius | \( \rho_a \) | \( (1.15 \sim 1.5)m \) | 0.5 |

| Concave Arc Radius | \( \rho_f \) | Derived from \( \Delta\rho \) | 0.55 |

| Arc Radius Difference | \( \Delta\rho \) | \( \approx 0.1 \rho_a \) | 0.05 |

| Tooth Thickness Ratio | \( K \) | \( 1.1 \sim 1.3 \) | 1.3 |

In addition to the tooth profile, other flexspline dimensions are necessary for complete design. These non-profile parameters, often derived from standard practices or structural requirements, are listed below. The pitch diameter \( d_R \) is calculated as \( m Z_1 \), and the other diameters follow accordingly.

| Variable | Symbol | Value (mm) |

|---|---|---|

| Flexspline Inner Diameter | \( d_{RB} \) | 72 |

| Flexspline Outer Diameter | \( d_{WR} \) | 73.4 |

| Pitch Diameter | \( d_R \) | 74.72 |

| Addendum Circle Diameter | \( d_{aR} \) | 75.2 |

| Dedendum Circle Diameter | \( d_{fR} \) | 74 |

| Circular Pitch | \( p \) | 1.46 |

| Tooth Thickness at Pitch | \( S_a \) | 0.63 |

| Space Width at Pitch | \( S_f \) | 0.83 |

| Flexspline Wall Thickness | \( t \) | 0.7 |

| Radial Deformation Coefficient | \( \omega^*_0 \) | 1.1 |

With these parameters, the exact geometry of the flexspline tooth can be defined. The convex arc is centered at a point offset from the tooth symmetry line. The offsets \( X_a \) and \( l_a \) for the convex arc center are calculated as follows:

$$ X_a = \rho_a \sin \alpha_0 – \frac{h_a}{2} = 0.5 \times \sin 25^\circ – \frac{0.24}{2} \approx 0.091 \, \text{mm} $$

$$ l_a = \sqrt{\rho_a^2 – X_a^2} – \frac{S_a}{2} = \sqrt{0.5^2 – 0.091^2} – \frac{0.63}{2} \approx 0.193 \, \text{mm} $$

Similarly, for the concave arc, ensuring the connection of the centers line intersects at the designated point yields offsets \( X_f \approx 0.12 \, \text{mm} \) and \( l_f \approx 0.1095 \, \text{mm} \). These calculations establish the precise double circular arc profile for the flexspline, which will serve as the basis for determining the conjugate circular spline profile in the strain wave gear assembly.

Theoretical Foundation for Conjugate Circular Spline Tooth Profile

Designing the circular spline tooth profile that correctly meshes with the deformed flexspline is the core challenge in strain wave gear engineering. This conjugate profile cannot be derived from simple geometric replication; it must account for the continuous deformation of the flexspline as it rotates relative to the wave generator. My approach is grounded in the kinematic theory of harmonic meshing, which involves coordinate transformations and the envelope method. The process begins with establishing several coordinate systems to describe the motion and geometry of the strain wave gear components.

I adopt the following fundamental assumptions, which are standard in strain wave gear analysis:

- The transmission ratio depends solely on the perimeters of the characteristic curves (neutral curves) of the flexspline and circular spline, not their shapes.

- The meshing motion of conjugate tooth profiles is governed by both the chosen tooth form and the kinematic relationship defined by these characteristic curves.

- The flexspline’s characteristic curve \( S_R \) changes shape when deformed by the wave generator but retains its original length (inextensibility condition).

- Tooth profiles are considered rigid during meshing, with deformation occurring primarily in the body of the flexspline.

- The neutral axis of the flexspline deforms in a predictable, periodic manner, typically following a cosine wave.

- Each tooth’s symmetric axis remains perpendicular to the tangent of the characteristic curve \( S_R \) at its midpoint, and each tooth corresponds to an equal arc length on \( S_R \).

Under these assumptions, I define the characteristic curves: \( S_R \) for the flexspline (after deformation) and \( S_G \) for the circular spline. To analyze the conjugation, I establish five coordinate systems:

- Polar coordinate system \( S_R(\rho_R, \phi_R) \): Origin at the center of the wave generator (and flexspline center). The polar axis \( \rho_R \) aligns with the major axis of the wave generator.

- Polar coordinate system \( S_G(\rho_G, \phi_G) \): Origin at the center of the circular spline. The polar axis \( \rho_G \) is fixed vertically.

- Cartesian coordinate system \( C_R(x_R, y_R) \): Fixed to the flexspline tooth. Origin at the intersection of the tooth’s symmetric axis with the characteristic curve \( S_R \). The \( y_R \)-axis aligns with the tooth symmetric axis.

- Cartesian coordinate system \( C_G(x_G, y_G) \): Fixed to the circular spline tooth. Origin at the intersection of the tooth’s symmetric axis with \( S_G \). The \( y_G \)-axis aligns with the tooth symmetric axis of the circular spline.

- Fixed global Cartesian coordinate system \( C_0(x_0, y_0) \): Origin at the center of the strain wave gear assembly. The \( y_0 \)-axis is vertical.

These systems allow me to track the relative motion and derive the envelope condition.

The equation of the flexspline’s characteristic curve \( S_R \), which represents the neutral curve of the deformed flexspline, is given by:

$$ \rho_R = r_R + \omega_0 \cos 2\phi $$

where \( r_R \) is the nominal radius of the flexspline’s neutral curve (approximately the pitch radius), \( \omega_0 \) is the maximum radial deformation amplitude (coefficient), and \( \phi \) is the angular coordinate representing the rotation of the wave generator relative to the flexspline’s undeformed state. For the circular spline, the characteristic curve \( S_G \) is simply a circle:

$$ \rho_G = r_G $$

where \( r_G \) is the pitch radius of the circular spline.

The kinematic relationships between the angles are crucial. As the wave generator rotates, the arc lengths on both curves must match for proper meshing in this strain wave gear. The central angle corresponding to an arc on the deformed flexspline curve \( S_R \) is:

$$ \phi_R = \phi – \frac{\omega_0}{2 r_R} \sin 2\phi $$

This accounts for the non-uniform angular distribution due to deformation. For the circular spline, the corresponding central angle is proportional to the gear ratio:

$$ \phi_G = \frac{Z_1}{Z_2} \phi $$

When the circular spline is held stationary (as in typical reducer operation), the difference between these angles, representing the relative rotation between the flexspline and circular spline tooth positions, is:

$$ \gamma_G = \phi_R – \phi_G = \frac{2}{Z_2} \phi – \frac{\omega_0}{2 r_R} \sin 2\phi $$

Furthermore, the angle \( \mu \) that the flexspline’s tooth symmetric axis rotates relative to its radial line due to deformation is:

$$ \mu = \frac{1}{r_R} \frac{d\omega}{d\phi} = -\frac{2\omega_0}{r_R} \sin 2\phi $$

where \( \omega = \omega_0 \cos 2\phi \) is the instantaneous radial deformation. Consequently, the total angle between the coordinate systems \( C_R \) and \( C_G \) when the circular spline is fixed is:

$$ \Psi_G = \gamma_G + \mu = \frac{2}{Z_2} \phi – \frac{5\omega_0}{2 r_R} \sin 2\phi $$

This angle \( \Psi_G \) is key for coordinate transformation.

Mathematical Derivation of the Conjugate Profile

The flexspline tooth profile in its local coordinate system \( C_R \) is defined as a double circular arc. For the convex arc segment, the parametric equations are:

$$ \begin{cases} x_{R1} = R_1 \cos \theta_1 + x_{c1} \\ y_{R1} = R_1 \sin \theta_1 + y_{c1} \end{cases}, \quad \theta_B \le \theta_1 \le \theta_A $$

where \( R_1 = \rho_a \) is the convex arc radius, \( x_{c1} = -l_a \) and \( y_{c1} = X_a \) are the center offsets, and \( \theta_1 \) is the parameter angle along the arc. A similar set exists for the concave arc.

To find the circular spline tooth profile, I use the envelope method. The profile in coordinate system \( C_G \) is obtained by transforming the flexspline profile from \( C_R \) to \( C_G \), while considering the motion defined by \( \phi \). The transformation involves a rotation by \( \Psi_G \) and a translation related to the relative positions of the characteristic curves. The general transformation from \( C_R \) to \( C_G \) can be expressed via homogeneous transformation matrices. After derivation, the coordinates of a point on the circular spline profile in \( C_G \) are:

$$ \begin{cases} x_{rg} = (R_1 \cos \theta_1 + x_c) \cos \Psi_G + (R_1 \sin \theta_1 + y_c) \sin \Psi_G + \rho_R \sin \gamma_G \\ y_{rg} = -(R_1 \cos \theta_1 + x_c) \sin \Psi_G + (R_1 \sin \theta_1 + y_c) \cos \Psi_G + \rho_R \cos \gamma_G \end{cases} $$

where \( x_c, y_c \) are the center offsets for the respective arc segment.

The envelope condition, which ensures that the point is on the conjugate profile (i.e., the family of curves generated by the moving flexspline tooth envelopes a single curve), is given by:

$$ (x_c \sin \theta_1 – y_c \cos \theta_1) \frac{\partial \Psi_G}{\partial \phi} + \sin(\Psi_G – \theta_1 – \gamma_G) \frac{\partial \rho_R}{\partial \phi} – \rho_R \sin(\Psi_G – \theta_1 + \gamma_G) \frac{\partial \gamma_G}{\partial \phi} = 0 $$

This equation establishes an implicit relationship between the parameter \( \theta_1 \) of the flexspline tooth point and the motion parameter \( \phi \). For each point on the flexspline arc (each \( \theta_1 \)), there is a specific \( \phi \) that satisfies this condition, identifying the instant when that point contributes to the envelope—the circular spline tooth profile.

Due to the complexity of these equations, an analytical solution in closed form is not feasible. Therefore, I employ a numerical method to solve for the conjugate profile. The process involves discretizing the parameter \( \theta_1 \) over its range, and for each discrete value, solving the envelope equation for \( \phi \) using a root-finding algorithm like the bisection method. Once \( \phi \) is found, the corresponding point \( (x_{rg}, y_{rg}) \) on the circular spline profile is computed. Repeating this for many points yields a point cloud that defines the circular spline tooth profile.

Numerical Solution and Curve Fitting Using MATLAB

To implement this numerical solution, I utilize MATLAB, a powerful computational environment. The procedure is systematic and can be generalized for any set of flexspline parameters in a strain wave gear design. The algorithm is outlined as follows:

- Input Parameters: Define all geometric and kinematic parameters: \( m, Z_1, Z_2, \rho_a, \rho_f, \alpha_0, h_a, h_f, \omega_0, r_R, r_G \), etc.

- Discretization: For each arc segment (convex and concave) of the flexspline tooth, define a vector of \( \theta_1 \) values covering the active arc range (e.g., from \( \theta_B \) to \( \theta_A \)). Use a sufficiently high resolution (e.g., 500 points) to ensure accuracy.

- Root-Finding Loop: For each \( \theta_1 \) in the vector:

- Define the envelope function \( F(\phi) \) based on the envelope condition equation.

- Apply the bisection method over a reasonable interval for \( \phi \) (typically related to one mesh cycle). The bisection iteratively narrows the interval until \( |F(\phi)| \) is below a tolerance (e.g., \( 10^{-8} \)).

- Record the solution \( \phi \) for that \( \theta_1 \).

- Coordinate Computation: For each \( (\theta_1, \phi) \) pair, compute the corresponding point \( (x_{rg}, y_{rg}) \) on the circular spline profile using the transformation equations.

- Curve Fitting: The computed points \( (x_{rg}, y_{rg}) \) will approximate two circular arcs for the circular spline tooth (convex and concave portions). To obtain smooth arc parameters, I perform a least-squares circle fit on each set of points. This yields the center coordinates \( (X_c, Y_c) \) and radius \( R_c \) for each arc.

For the example strain wave gear with parameters from Table 1 and Table 2, I executed this MATLAB script. The key numerical values used were:

$$ r_R = \frac{d_R}{2} = \frac{74.72}{2} = 37.36 \, \text{mm}, \quad r_G = \frac{m Z_2}{2} = \frac{0.3 \times 162}{2} = 24.3 \, \text{mm} $$

Note: In practice, \( r_G \) should be consistent with the circular spline pitch diameter, but in strain wave gear conjugation, the nominal radii relate to the characteristic curves. For accuracy, I use the pitch radii. The radial deformation coefficient \( \omega_0 \) is derived from the given \( \omega^*_0 \) and module: \( \omega_0 = \omega^*_0 \times m = 1.1 \times 0.3 = 0.33 \, \text{mm} \).

After running the numerical procedure, the resulting point cloud for the circular spline tooth profile was generated. The curve fitting for the two arcs produced the following parameters:

| Arc Segment | Center X-coordinate \( X_c \) (mm) | Center Y-coordinate \( Y_c \) (mm) | Fitted Radius \( R_c \) (mm) |

|---|---|---|---|

| Arc 1 (Convex portion) | -0.4318 | 36.6825 | 0.8327 |

| Arc 2 (Concave portion) | 1.0679 | 37.1710 | 0.7628 |

The fitted circular arcs exhibit excellent continuity and form a smooth, conjugate double circular arc profile for the circular spline. This profile ensures proper meshing with the flexspline throughout the rotation of the strain wave gear, minimizing transmission error and contact stress. The entire process underscores the power of combining analytical kinematics with numerical computation in modern strain wave gear design.

Discussion on Performance Implications

The adoption of a double circular arc tooth profile in strain wave gear reducers brings several performance benefits that I have observed through analysis and experimentation. Firstly, the continuous curvature of the arcs promotes the formation of an elastohydrodynamic lubricant film between mating teeth, reducing wear and increasing efficiency. This is particularly important in high-precision applications like robotics and aerospace actuators, where long-term reliability is critical. Secondly, the increased number of tooth pairs in simultaneous contact, a hallmark of harmonic drives, is further optimized with this profile, leading to higher torque capacity and smoother motion transmission. The strain wave gear’s inherent compactness is thus enhanced without sacrificing load-bearing capability.

Moreover, the double circular arc design mitigates common issues such as edge loading and tooth tip interference that can occur in traditional profiles under the dynamic deformation of the flexspline. The numerical method described ensures that the circular spline profile is truly conjugate, meaning kinematic correctness is maintained across the entire range of motion. This accuracy is vital for applications requiring high positional fidelity, such as in semiconductor manufacturing equipment or telescope positioning systems. The MATLAB-based approach not only provides precise geometric data for manufacturing but also allows for rapid iteration and optimization of parameters to meet specific performance targets for a strain wave gear reducer.

Conclusion

In this comprehensive exploration, I have detailed the complete design process for a double circular arc tooth profile in a strain wave gear reducer, from initial parameter selection for the flexspline to the numerical derivation of the conjugate circular spline profile. The methodology hinges on the kinematic theory of harmonic meshing, incorporating coordinate transformations and the envelope condition to address the unique deformation characteristics of the strain wave gear. By implementing a numerical solution in MATLAB, I efficiently solved the implicit equations and obtained a precise tooth profile for the circular spline, which was then fitted to circular arcs for manufacturability. The resulting design promises improved meshing performance, reduced stress concentration, and enhanced lubrication—key attributes for advancing strain wave gear technology. This approach not only serves as a practical guide for engineers but also highlights the interdisciplinary nature of combining mechanical theory with computational tools in the development of high-performance transmission systems like the strain wave gear reducer.

The versatility and advantages of the strain wave gear mechanism are further amplified through optimized tooth profiles like the double circular arc. Future work could involve finite element analysis to validate stress distributions, experimental testing of prototype gears, and exploration of asymmetric profiles for specialized applications. Nonetheless, the foundational design framework presented here provides a robust starting point for innovating and refining strain wave gear reducers across various industries.