As a design engineer specializing in precision measurement tools, I have often encountered the challenge of efficiently and accurately inspecting spur gears in industrial settings. The spur gear, a fundamental component in mechanical transmission systems, requires meticulous quality control to ensure optimal performance. One critical parameter for spur gears is the pitch diameter, but for odd-tooth spur gears, direct measurement of the pitch diameter is impractical with simple gauges. Therefore, the industry standard is to measure the over pins distance (OPD), which indirectly ensures the pitch diameter’s accuracy. This article details my first-hand experience in designing a specialized gauge for measuring the OPD of odd-tooth spur gears, focusing on achieving high precision and production-line efficiency. Throughout this discussion, the term ‘spur gear’ will be emphasized, as it is central to our application.

The impetus for this project came from a specific industrial need: a flanged shaft component featuring a 33-tooth spur gear required 100% inspection of its OPD in high-volume production. The theoretical OPD dimension was specified as (28.84 – 28.89) mm using a gauge pin diameter of 1.6 mm. Traditional methods using micrometers or calipers across two gauge pins inserted into opposite tooth spaces were too slow, creating a bottleneck. My goal was to create a comparative gauge that could perform a five-point measurement on each spur gear component in under two minutes, with stringent accuracy requirements: a repeatability of 0.005 mm and an indication error within ±0.05 mm of 0.01 mm when calibrated against a master standard.

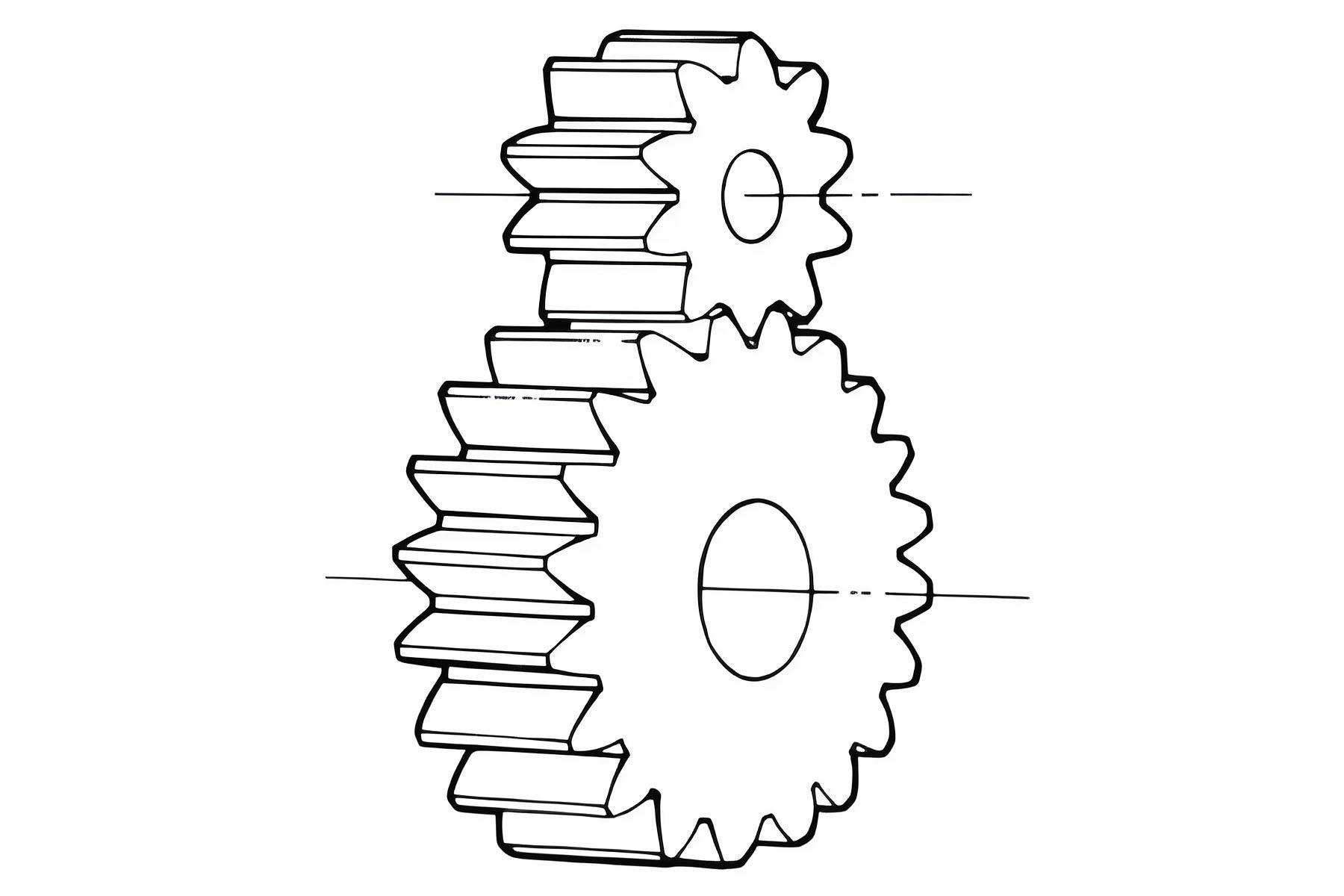

The core principle of the gauge relies on the established method for calculating the over pins distance for an external spur gear. For an odd-tooth spur gear, the measurement involves placing two precision gauge pins in diametrically opposite tooth spaces. The distance across the outer surfaces of these pins defines the OPD. The theoretical value depends on the spur gear’s fundamental parameters. The formula for the pin diameter (d_p) selection and the resulting OPD (M) is derived from gear geometry. For a spur gear with number of teeth (z), module (m), pressure angle (α), and profile shift coefficient (x), the relevant equations are:

The transverse pressure angle in the plane of measurement is crucial. The involute function is defined as inv(α) = tan(α) – α. The angle to the center of the gauge pin from the gear center, θ_v, must be calculated. For an odd-tooth spur gear, the pins are not perfectly diametrically opposite relative to tooth indices, but the measurement is taken across pins situated 180 degrees apart around the gear’s circumference. The formula for the distance over pins (M) for an external spur gear with an odd number of teeth is given by:

$$ M = d_b \times \frac{\cos(\alpha)}{\cos(\alpha_v)} + d_p $$

where \( d_b \) is the base diameter of the spur gear (\( d_b = m \cdot z \cdot \cos(\alpha) \)), and \( \alpha_v \) is the pressure angle at the point of contact with the pin. The value of \( \alpha_v \) is found by solving the equation:

$$ \text{inv}(\alpha_v) = \text{inv}(\alpha) + \frac{d_p}{d_b} – \frac{\pi}{2z} + \frac{2x \cdot \tan(\alpha)}{z} $$

For our specific spur gear application with 33 teeth, a module of 0.8 mm (implied from the context), and a standard pressure angle of 20°, the calculation yields the theoretical OPD range. To facilitate design, I created a parameter table summarizing the spur gear data and gauge requirements:

| Parameter | Symbol | Value / Specification |

|---|---|---|

| Number of Teeth | \( z \) | 33 (odd) |

| Module | \( m \) | 0.8 mm (assumed from context) |

| Pressure Angle | \( \alpha \) | 20° |

| Profile Shift Coefficient | \( x \) | 0 (assuming standard) |

| Gauge Pin Diameter | \( d_p \) | 1.6 mm |

| Theoretical Over Pins Distance | \( M \) | 28.84 – 28.89 mm |

| Required Gauge Repeatability | – | 0.005 mm |

| Indication Error within ±0.05 mm | – | 0.01 mm |

| Measurement Points per Spur Gear | – | 5 |

| Target Inspection Time | – | < 2 minutes |

The functional implementation of the gauge addresses three core aspects: part handling and location, deviation sensing, and readout. For the spur gear component, which is part of a flanged shaft, I chose the shaft’s center holes as the primary datum. The gauge incorporates a fixed center and a retractable spring-loaded center to quickly locate and clamp the part axially. A cam-operated lever mechanism simultaneously retracts the measurement anvils, allowing for easy loading and unloading of the spur gear component. This mechanism directly impacts efficiency, a critical requirement for inspecting every spur gear in the batch.

The heart of the measurement system is a custom-built two-point internal caliper-style sensing head. The anvils of this head are designed to contact the gauge pins inserted into the opposite tooth spaces of the spur gear. The angle between the two anvils is precisely set to match the theoretical included angle subtended by the two contact points on the gauge pins relative to the gear center. This angle \( \beta \) for our odd-tooth spur gear can be approximated as:

$$ \beta \approx \frac{180^\circ}{z} $$

but more accurately, it is derived from the geometry of the gauge pin contact. One anvil is fixed (but adjustable for alignment), and the other is connected to a linear movement mechanism that transfers displacement to a high-precision dial indicator. The gauge is a comparative instrument; it is zeroed using a master spur gear artifact of known OPD. Any deviation in the manufactured spur gear’s OPD is then directly read from the dial indicator.

Ensuring measurement accuracy was a multifaceted challenge. The first step was procuring a master spur gear component whose OPD was calibrated by a primary method (e.g., a coordinate measuring machine) with an uncertainty significantly less than the gauge’s required error. This master spur gear becomes the reference for all measurements.

The gauge’s mechanical errors were the next focus. The main contributors to indication error and repeatability are: 1) the error in the anvil angle \( \Delta \beta \), 2) misalignment of the anvil contact points relative to the spur gear’s axis (centering error), and 3) errors from the dial indicator itself. A sensitivity analysis helps quantify these effects. Let \( \Delta M \) be the error in measured OPD. For small errors, we can write:

$$ \Delta M \approx \frac{\partial M}{\partial \beta} \Delta \beta + \frac{\partial M}{\partial e} \Delta e + \Delta I $$

where \( e \) represents centering error and \( \Delta I \) is the indicator error. The partial derivative \( \frac{\partial M}{\partial \beta} \) can be derived from the geometry of the spur gear and gauge pin contact. To simplify manufacturing and assembly, I designed the anvil mounting structure with adjustable elements. The fixed anvil block is attached to the main body via a shim or wedge, allowing the anvil angle \( \beta \) to be fine-tuned after assembly by lapping the shim. Similarly, the fixed anvil itself has a fine-thread adjustment for radial position, enabling correction of centering error after the angle is set. This modular, adjustable approach proved far more economical than attempting to machine all components to ultra-tight tolerances in a single setup.

The dial indicator selected has a specified repeatability of 0.003 mm and a linearity error of 0.005 mm within its measuring range. To isolate the measurement head from the operator’s hand pressure and the gauge’s own weight, I implemented a floating support system. The entire sensing head assembly is mounted on a counterbalanced parallelogram mechanism or low-friction linear slides, allowing it to align freely with the spur gear’s measurement plane under minimal force. This dramatically improves repeatability by eliminating side forces and moment loads on the anvils.

The detailed realization process involved careful mechanical design. The main body houses the fixed center and the sliding mechanism for the retractable center. A cam lever, when actuated, moves a slide that, through a linkage, retracts the movable anvil. This ensures the anvils are fully open during part loading. Releasing the cam lever allows a spring to bring the movable anvil into contact with one gauge pin. The fixed anvil contacts the opposite pin. The linkage is designed to provide a consistent and moderate measuring force, essential for repeatable contact with the spur gear’s gauge pins. The dial indicator is mounted in a clamp that allows for easy zero-setting against the master spur gear.

To illustrate the alignment and adjustment parameters, consider the following table summarizing key design dimensions and tolerances for the gauge’s critical components:

| Component/Feature | Design Value | Tolerance/Objective | Comment |

|---|---|---|---|

| Anvil Included Angle (β) | Calculated from spur gear geometry | ± 2 arc minutes | Achieved via adjustable shim |

| Anvil Tip Radius | 0.8 mm (to match pin curvature) | ± 0.01 mm | Ensures point contact on gauge pin |

| Anvil Centering relative to Axis | 0 (perfect alignment) | ± 0.005 mm radially | Adjusted via fixed anvil thread |

| Measuring Force | 1.5 – 2.0 N | ± 0.3 N | Controlled by spring in linkage |

| Floating Support Stiffness | Low in measurement direction | High in perpendicular directions | Prevents rocking, allows compliance |

| Cam Lever Actuation Travel | ≥ 5 mm anvil retraction | Smooth, positive lock in open position | For easy spur gear loading |

The use of the gauge follows a defined procedure to maximize reliability. First, the master spur gear is mounted on the centers. The cam lever is released, allowing the anvils to contact the gauge pins inserted in the master spur gear. The dial indicator is then set to zero. The master is removed, and a production spur gear component is loaded. The measurement is taken by simply releasing the cam lever and reading the indicator. To perform a five-point check, the spur gear is rotated relative to the gauge. After recording a measurement at one position, the cam lever is actuated to retract the anvils, the spur gear is rotated by approximately \( \frac{360^\circ}{5} = 72^\circ\) (or a corresponding number of teeth to land in a different pair of spaces), and the lever is released for the next measurement. This process is repeated five times. The entire sequence, including loading, five measurements, and unloading, was timed and consistently completed within 120 seconds, meeting the production target.

The gauge’s performance was validated through a Gauge Repeatability and Reproducibility (GR&R) study. Using a set of ten spur gear components spanning the tolerance range, multiple operators performed multiple five-point measurements. The calculated GR&R value was less than 10% of the part tolerance, confirming the gauge’s capability for process control. The inherent geometric and runout errors of the spur gear itself mean that measuring at multiple points is necessary to get a representative OPD value. The floating anvil design accommodates slight misalignments during this rotation without binding.

In conclusion, the development of this specialized gauge successfully addresses the intricate challenge of high-speed, precise measurement of the over pins distance in odd-tooth spur gears. By employing a comparative measurement principle with a cleverly designed two-point contact mechanism, adjustable alignment features, and a floating support system, the gauge achieves a balance between accuracy, repeatability, and operational speed. The design philosophy centered on the spur gear’s unique geometry, and the emphasis on adjustability during assembly proved to be a cost-effective strategy for achieving the required precision. This gauge exemplifies how dedicated metrology tooling can be engineered to keep pace with modern manufacturing demands for critical components like spur gears, ensuring quality without compromising throughput. The principles discussed here—from the fundamental spur gear equations to the practical mechanical design considerations—can be adapted for other gear types and measurement scenarios, underscoring the versatility of focused gauge design.