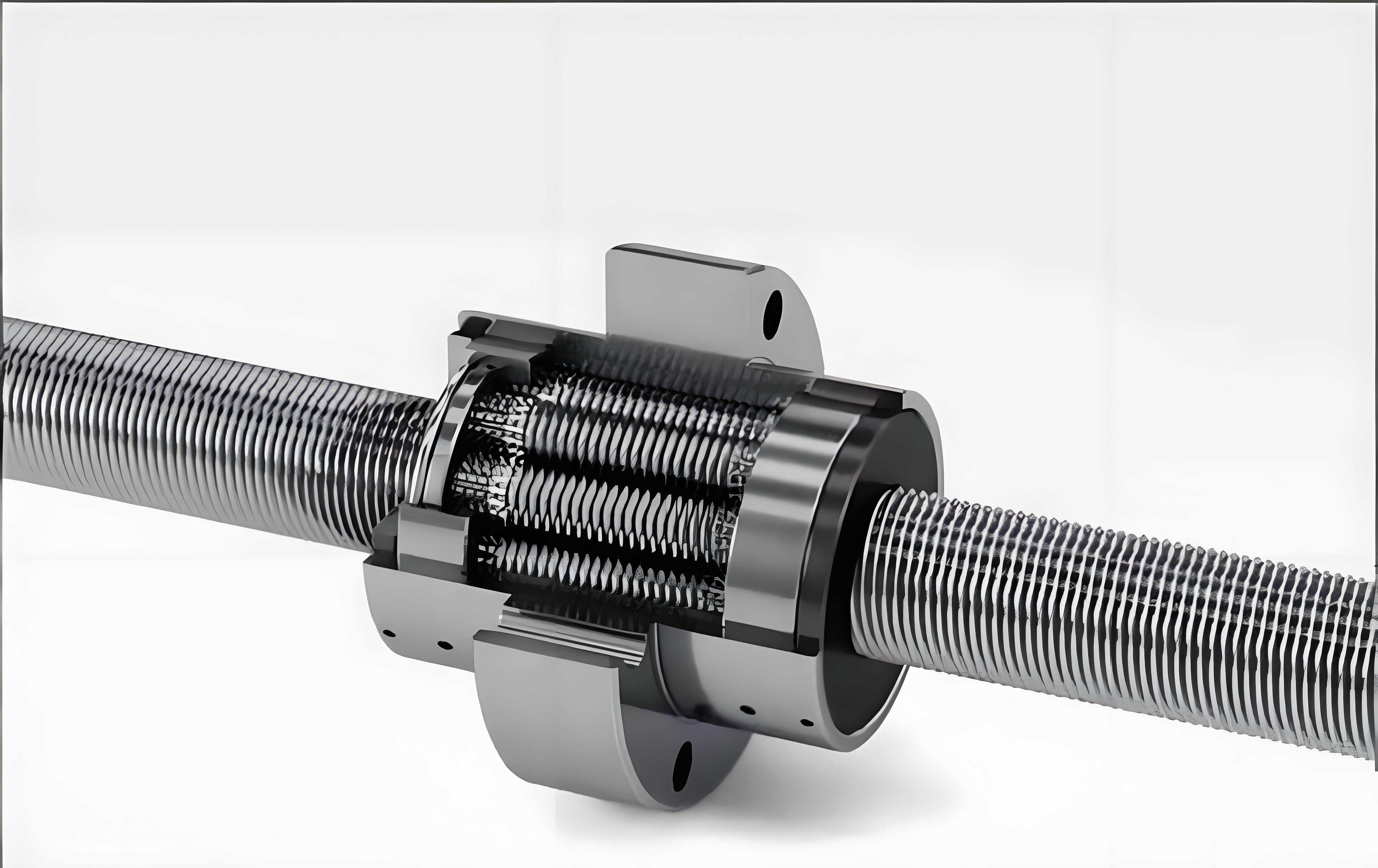

The planetary roller screw assembly (PRSA) represents a highly efficient and robust mechanism for converting rotary motion into precise linear actuation. Unlike conventional ball screws, the planetary roller screw assembly utilizes multiple threaded rollers arranged planetarily around a central screw, engaging with an internal nut. This configuration offers superior load distribution, higher stiffness, greater dynamic load capacity, and longer operational life. Due to these exceptional characteristics, the planetary roller screw assembly is indispensable in demanding applications such as aerospace flight control systems, missile actuation, precision machine tools, and high-performance industrial automation. The design and analysis of such a complex assembly require a meticulous approach, combining theoretical parameter derivation with advanced simulation techniques to ensure reliability and performance.

1. Parametric Design of the Planetary Roller Screw Assembly

The fundamental operation of the planetary roller screw assembly relies on precise geometric relationships between its core components: the central screw, the planetary rollers, and the nut. The rollers are housed within a carrier (or cage) and mesh simultaneously with the screw and the nut. An internal gear ring (or synchronized ring) at each end of the nut engages with gear teeth on the ends of the rollers, ensuring proper phasing and preventing relative circumferential slip. For a constant transmission ratio and smooth operation, the lead of the screw (PS), the lead of the rollers (PR), and the leads within the nut must satisfy specific kinematic conditions. A common design uses a multi-start screw thread. The basic geometric and kinematic relationship is given by:

$$ \frac{P_S}{P_R} = 1 + \frac{d_N}{d_S} $$

Where dS is the screw pitch diameter and dN is the nut pitch diameter. Furthermore, for proper engagement and assembly of N rollers, the angular offset (α) between successive rollers in the assembly is critical. This is determined by ensuring the circumferential distance traveled by a point on a roller due to its gearing with the internal ring equals the distance to the next roller position. The angle is derived from:

$$ \frac{360}{N} \cdot \pi \cdot \left( \frac{d_N}{2} + \frac{d_R}{2} \right) = \pi \cdot d_R \cdot \frac{\alpha}{360} $$

Which simplifies to: $$ \alpha = \frac{360}{N} \cdot \left( \frac{d_N + d_R}{d_R} \right) $$

Based on these principles and desired performance specifications (e.g., load capacity, speed), the key design parameters for a representative planetary roller screw assembly are calculated and summarized in the table below.

| Component / Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Screw Pitch Diameter | dS | 30.0 | mm |

| Screw Lead | PS | 10.0 | mm |

| Screw Starts | – | 5 | – |

| Screw Pitch | – | 2.0 | mm |

| Screw Length | LS | 500.0 | mm |

| Roller Pitch Diameter | dR | 6.0 | mm |

| Roller Lead | PR | 2.0 | mm |

| Roller Length | LR | 90.0 | mm |

| Number of Rollers | N | 11 | – |

| Roller End Gear Teeth | ZR | 12 | – |

| Nut Pitch Diameter | dN | 42.0 | mm |

| Thread Profile Angle | – | 90 | ° |

| Angular Roller Offset (α) | α | 229.09 | ° |

These parameters form the foundation for creating a detailed digital model of the planetary roller screw assembly. Performance metrics such as static load capacity, fatigue life, and efficiency can be estimated from these dimensions, though finite element analysis provides a much more accurate assessment.

2. Digital Modeling and Virtual Assembly

Accurate three-dimensional modeling is a prerequisite for any meaningful simulation. Using SolidWorks, a parametric model of each component in the planetary roller screw assembly was developed. The screw was modeled with a 5-start, 90° triangular thread profile. The rollers required intricate features including the planetary thread and the end spur gear teeth, which were generated using precise gear modeling tools and Boolean operations. The nut model incorporated the internal thread and features for mounting a flange. The internal gear ring, which meshes with the roller end gears, was also parametrically modeled to ensure correct tooth geometry and engagement.

The virtual assembly of the planetary roller screw assembly was conducted with strict adherence to kinematic constraints. The nut was fixed as the base component. The internal gear ring was assembled concentrically and axially positioned. The carrier (retainer/cage) was then inserted and concentrically aligned. A single roller was assembled into its corresponding hole in the carrier, with its axis concentric and its end gear teeth phased correctly with the internal ring. Crucially, the thread helix of this first roller must be correctly phased with the screw thread. The screw was then inserted, and its thread phase was adjusted to mesh perfectly with the roller’s thread without interference.

Subsequent rollers were added using the calculated angular offset (α = 229.09°) between their front reference planes to ensure uniform circumferential distribution and proper simultaneous engagement with both the screw and the nut threads. This process was repeated for all 11 rollers. A comprehensive interference check was performed on the complete planetary roller screw assembly model to validate the assembly logic and confirm the absence of geometric clashes, ensuring the theoretical design was physically realizable.

3. Finite Element Analysis of the Planetary Roller Screw Assembly

To evaluate the structural performance under operational loads, a series of finite element analyses (FEA) were performed using the SolidWorks Simulation module. Given the symmetry and periodic nature of the planetary roller screw assembly, a sector model containing 1/11th of the full assembly—one roller in full engagement with corresponding sections of the screw and nut—was used. This significantly reduced computational cost while preserving analysis accuracy for contact stresses and deformations. All components were assigned the material properties of high-carbon chromium bearing steel (GCr15): Elastic Modulus E = 219 GPa, Poisson’s ratio ν = 0.3, Density ρ = 7830 kg/m³, Yield Strength σy = 518 MPa. Nonlinear contact conditions with a friction coefficient were defined between all threaded engagement surfaces (screw-roller and nut-roller).

3.1 Static Stress Analysis under Axial Load

A static axial load of 3000 N was applied to simulate a typical working condition. In the FEA setup, the nut and the screw end were fixed. The axial force was applied as a distributed load on one end-face of the roller, representing the force transmission path. The mesh was refined, especially in the thread contact regions, using a curvature-based mesh generator, resulting in a high-quality mesh with over 60,000 tetrahedral elements.

The von Mises stress distribution was examined to identify critical areas. The results revealed that the highest stresses occurred at the thread root and the crest of the engaged threads, particularly on the roller. This is characteristic of threaded connections where stress concentration is inevitable due to the geometry. The maximum stress was found to be below the material yield strength, indicating safety under this static load. The stress state can be evaluated using the von Mises yield criterion:

$$ \sigma_{v} = \sqrt{\frac{1}{2}[(\sigma_1 – \sigma_2)^2 + (\sigma_2 – \sigma_3)^2 + (\sigma_3 – \sigma_1)^2]} $$

Where σ1, σ2, σ3 are the principal stresses. The analysis confirmed that the design of this planetary roller screw assembly provides adequate static strength.

3.2 Displacement and Strain Analysis

The displacement analysis showed that under the 3000 N axial load, the maximum deformation occurred in the engaged thread regions. The screw exhibited a maximum deformation of approximately 0.005 mm, while the nut deformed about 0.002 mm. The deformation pattern indicated that the strain was more pronounced at the thread root (towards the minor diameter) compared to the crest. This is consistent with the bending behavior of a triangular thread tooth under load. The relationship between stress and strain in the elastic region follows Hooke’s Law, expressed in its generalized form for the axial direction as:

$$ \epsilon = \frac{\sigma}{E} $$

Where ε is the strain and σ is the normal stress. The contact analysis tool clearly visualized the load-bearing and non-bearing regions of the threads. The darker, high-pressure contact zones along the flanks represented the primary load transfer paths, while transparent areas indicated zones with little or no contact pressure. This insight is valuable for potentially optimizing the thread profile to enlarge the effective load-bearing contact area in future iterations of the planetary roller screw assembly design.

3.3 Modal Analysis

Modal analysis determines the natural frequencies and mode shapes of a structure, which is critical for avoiding resonant vibrations during operation. For this planetary roller screw assembly model, constraints were applied with one end of the screw fixed and the nut (positioned near the center) also fixed. The first six natural frequencies and their corresponding mode shapes were extracted. The results are summarized below:

| Mode Number | Frequency (Hz) | Primary Mode Shape Description |

|---|---|---|

| 1 | 293.1 | Lateral bending of the screw |

| 2 | 293.2 | Lateral bending (orthogonal direction) |

| 3 | 1,716.0 | Combined bending and higher-order deformation |

| 4 | 1,716.6 | Higher-order bending |

| 5 | 1,797.9 | Complex deformation involving nut/roller region |

The mass participation factors indicated that the largest displacements occurred in the X and Z lateral directions (up to ~0.5 mm) for the lower-frequency bending modes. This analysis identifies dangerous frequency ranges (e.g., near 293 Hz and 1716-1798 Hz) that should be avoided during the operation of the planetary roller screw assembly to prevent excessive vibration and potential loss of positioning accuracy.

3.4 Fatigue Analysis

Since the planetary roller screw assembly operates under cyclic loading, fatigue failure is a primary concern. A fatigue analysis was performed based on the static stress results, assuming fully reversed cyclic loading (R = -1) with a target life of 1,000,000 cycles. The S-N curve for GCr15 steel was used. The analysis produced life, damage, and factor of safety (load factor) plots.

The life plot showed that the shortest-lived components were localized areas on the crest and root of the roller threads, with a predicted life as low as 100 cycles in the most severe stress concentration spots. Larger areas of the roller thread had lives around 6,500 cycles. In contrast, most areas on the screw and nut threads showed a life well above 100,000 cycles. The factor of safety (FOS) plot, where FOS < 1 indicates potential failure, clearly highlighted the roller threads as the weakest link. The fatigue damage accumulation can be estimated using Miner’s rule:

$$ \sum_{i=1}^{k} \frac{n_i}{N_i} = 1 $$

Where ni is the number of cycles at a specific stress level and Ni is the number of cycles to failure at that stress level. The results strongly suggest that for the analyzed configuration of the planetary roller screw assembly, the planetary roller is the critical component for fatigue. A significant design insight emerged: the stress concentration is exacerbated where the roller’s threaded section meets its end gear teeth. One potential design improvement is to modify the roller end feature to be a pure gear, completely separate from the load-bearing thread, thereby eliminating this high-stress transition zone and potentially greatly enhancing the overall fatigue life of the planetary roller screw assembly.

4. Conclusion

This comprehensive study encompassed the parametric design, detailed digital modeling, and advanced finite element analysis of a planetary roller screw assembly. The kinematic and geometric design rules were successfully applied to derive key parameters and create an interference-free virtual prototype. The subsequent FEA provided deep insights into the structural behavior of the planetary roller screw assembly under load.

The static analysis confirmed the basic structural integrity under the designated axial load, with stress levels within the material’s elastic limit. The displacement and contact analysis revealed the actual load-bearing pattern on the thread flanks, offering a basis for potential profile optimization. Modal analysis identified critical natural frequencies to avoid during system design. Most importantly, the fatigue analysis pinpointed the planetary roller threads, especially at the transition to the end gear, as the most vulnerable elements for failure under cyclic loading. This critical finding directs future research and development efforts towards innovative roller designs—such as physically separating the thread and gear regions—to mitigate stress concentrations.

In summary, the integration of parametric design with high-fidelity finite element simulation forms a powerful methodology for developing and optimizing high-performance planetary roller screw assemblies. This approach enables engineers to predict performance, identify weaknesses, and innovate designs before physical prototyping, thereby accelerating development cycles and enhancing the reliability and load capacity of these sophisticated mechanical actuators. The continued refinement of analysis techniques and design strategies will further solidify the role of the planetary roller screw assembly as a premier solution for high-precision, high-load linear motion applications.