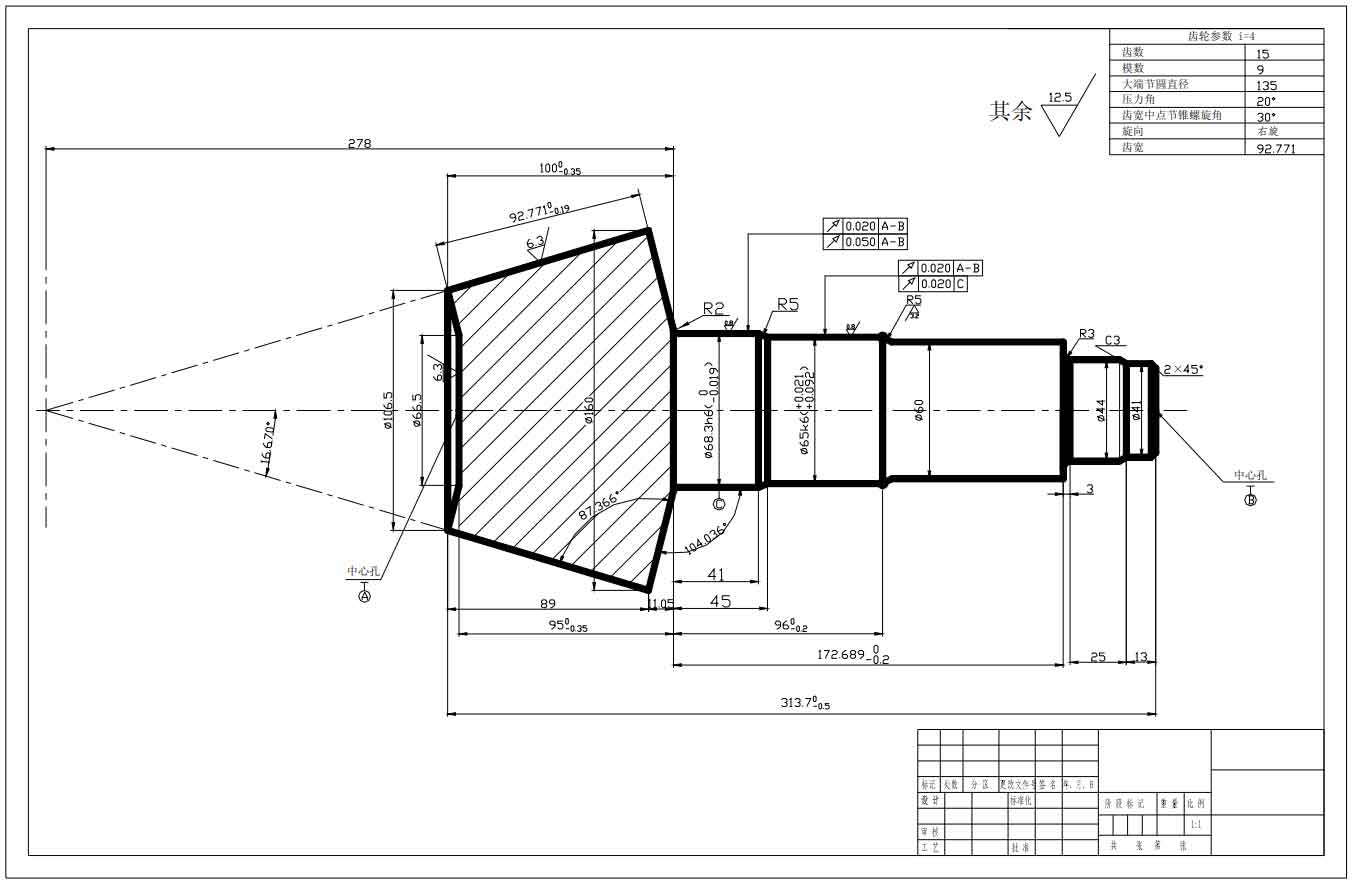

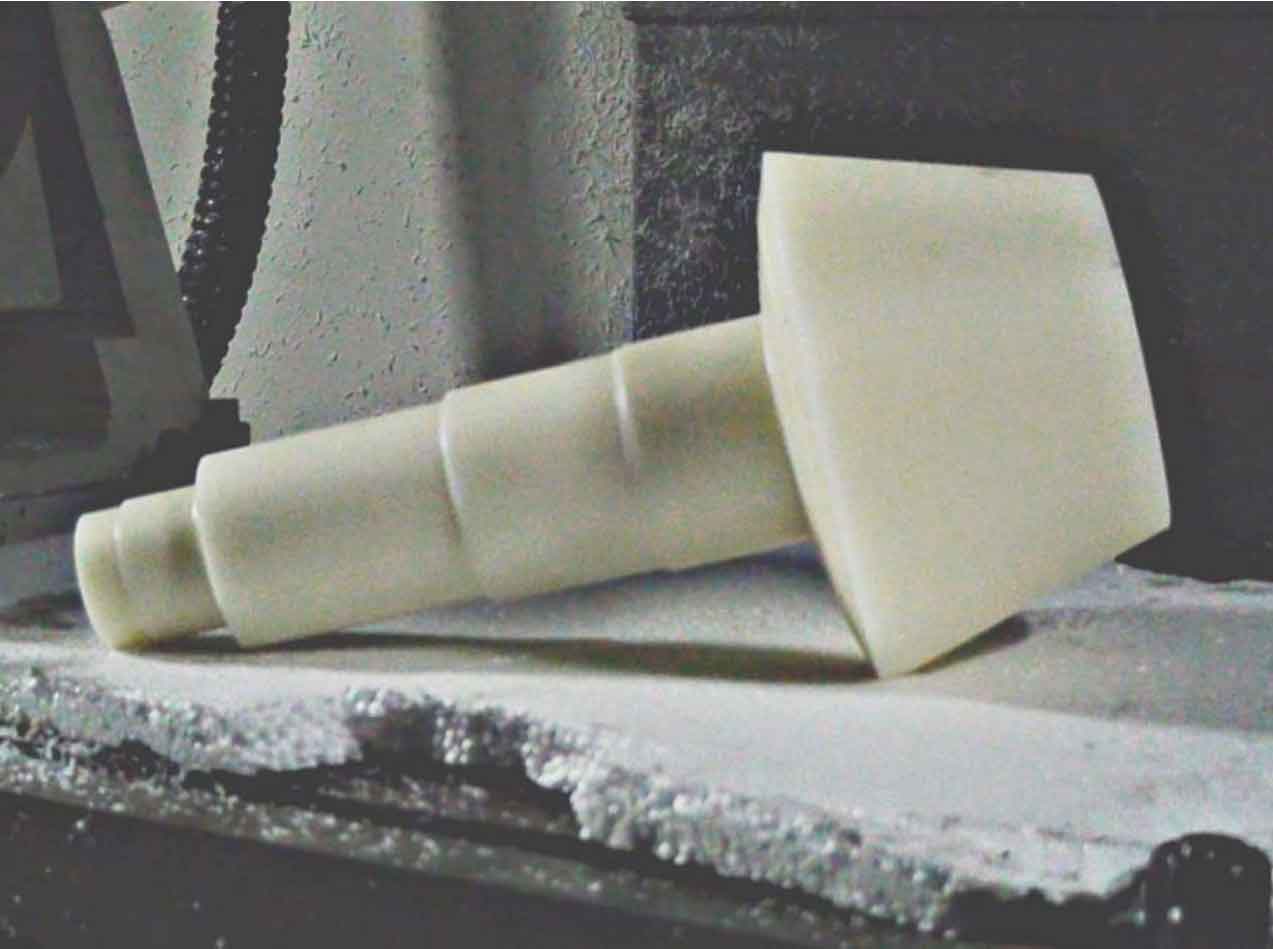

The tooth blank material selected for the tooth cutting experiment of spiral bevel gear is nylon, and the profile shape parameters refer to the tooth blank designed by simulation processing. According to the geometric parameters of spiral bevel gear blank. According to the key parameters of spiral bevel gear blank and the clamping requirements of gear blank fixture, the engineering drawing of spiral bevel gear blank to be processed is drawn by using CAD software, as shown in Figure 1. According to the engineering drawing, the tooth blank of spiral bevel gear is processed, as shown in Figure 2.

According to the design of spiral bevel gear cutting tool, the groove width at the tooth root of the small end of spiral bevel gear to be machined is 7.56mm and the full height of the tooth at the big end is 16.992, so the selected finger milling cutter must meet the following two requirements: ① the blade diameter must be less than 7.56mm; ② The tool length must be greater than 16.992. By consulting relevant data, for the processing of spiral bevel gear made of nylon, this paper selects the common finger milling cutter with cemented carbide blade, the model is Φ 6 * 15 * 50 * 2F * 55 °, see Figure 3 for the physical drawing of the tool.