The quest for enhanced efficiency and operational flexibility in agricultural irrigation machinery drives continuous innovation. Traditional hose reel irrigators often rely on hydraulic turbines for propulsion, which are inherently limited by low operational efficiency, typically below 20%, and a constrained speed adjustment range. This study focuses on the conceptual redesign and multi-objective optimization of the transmission system for a hose reel irrigator, specifically transitioning from a hydraulic turbine drive to a precisely controlled DC motor drive and integrating a high-ratio worm gears transmission. The primary goals are to significantly expand the speed ratio range, achieve a more compact design, and markedly improve the overall transmission efficiency.

1. Background and Motivation for Redesign

Conventional transmission systems in models like the JP75 often incorporate V-belt drives, multiple stages of spur gear reductions, and chain drives. A typical system, as shown in the schematic below, might involve four or five stages of spur gears to achieve the necessary high reduction ratios required for the slow travel speeds (8-60 m/h) of the sprinkler vehicle. Such configurations, while simple, suffer from several drawbacks:

- Low Overall Efficiency: Long transmission chains with multiple gear meshes, combined with belt drives, result in cumulative power losses, often leading to total system efficiencies below 55%.

- Bulky and Complex: Achieving a high total reduction ratio (e.g., 6,240 to 62,700) solely with spur gears necessitates many stages, increasing the size, weight, and complexity of the gearbox.

- Limited Low-Speed Performance: The hydraulic turbine’s efficiency plummets at lower rotational speeds, making it difficult to reliably achieve the required slow travel speeds without excessive energy waste.

The adoption of a permanent magnet brushless DC motor addresses the prime mover limitation, offering high efficiency across a wide speed range and excellent torque characteristics. However, this shift necessitates a complete re-evaluation of the transmission architecture to efficiently translate the motor’s high speed (e.g., 1500 rpm) to the sprinkler’s very low linear velocity.

2. Conceptual Design of the Worm Gear Based Transmission System

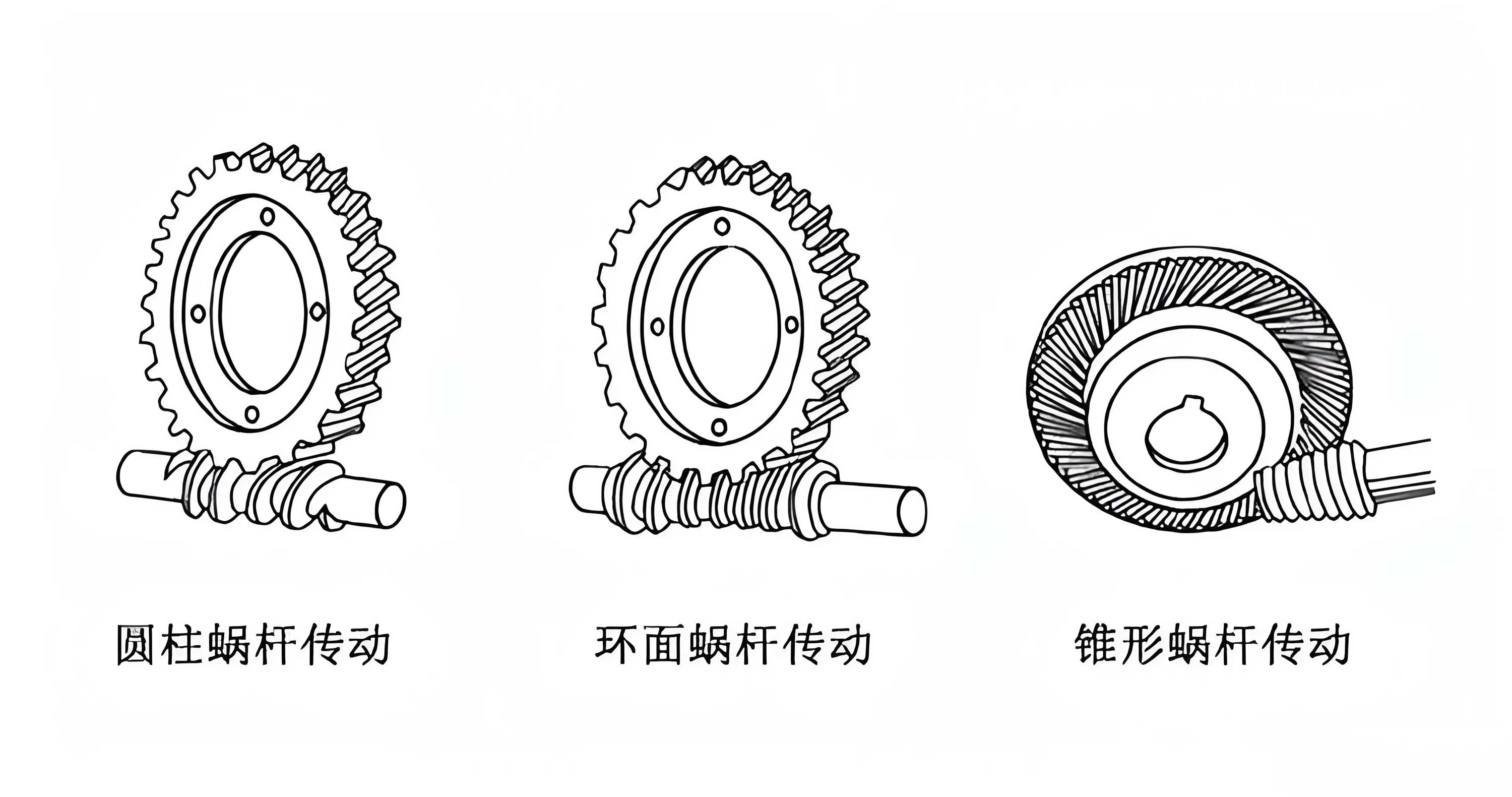

The core innovation in the new design is the strategic replacement of several spur gear stages with a single stage of worm gears. Worm gears are uniquely suited for this application due to their ability to provide very high single-stage reduction ratios (often up to 100:1 or more in compact spaces), smooth and quiet operation, and high shock load resistance.

The proposed two-speed transmission system is designed to cover the full operational range effectively. The system is schematically represented, featuring a worm gears pair as the primary first-stage reduction, followed by a set of spur gears arranged to provide two distinct speed paths, and finally a chain drive to the reel.

Gear Train Configuration:

- First Speed (Low Speed, High Torque): The power flow engages one path of spur gears after the worm gears. The total reduction ratio for Speed I ($i_I$) is given by:

$$ i_I = \frac{z_{b2} \cdot z_{b5} \cdot z_{b9} \cdot z_{b11}}{z_{b1} \cdot z_{b3} \cdot z_{b7} \cdot z_{b10}} $$

where $z_{bi}$ represents the number of teeth on gear $i$. - Second Speed (Higher Speed, Lower Torque): A sliding gear engages an alternative spur gear path, yielding a different ratio ($i_{II}$):

$$ i_{II} = \frac{z_{b2} \cdot z_{b6} \cdot z_{b9} \cdot z_{b11}}{z_{b1} \cdot z_{b4} \cdot z_{b7} \cdot z_{b10}} $$

The key difference lies in the ratio of the spur gear pairs ($z_{b5}/z_{b3}$ vs. $z_{b6}/z_{b4}$). - Worm Gear Stage: The worm gears pair ($z_{b1}$ – worm, $z_{b2}$ – worm wheel) provides the largest portion of the speed reduction in a single, compact stage, simplifying the overall layout and reducing the number of required spur gear stages.

Placing the worm gears at the input stage (connected to the motor) allows it to operate at a higher, more efficient speed and facilitates optimal lubrication as it can be partially immersed in the gearbox oil sump.

3. Mathematical Modeling for Optimization

To achieve the dual goals of maximum efficiency and minimum volume, precise mathematical models for efficiency calculation and volume estimation are established.

3.1 Modeling Transmission Efficiency

The total efficiency of the gearbox is the product of the efficiencies of its subsystems. For a closed gearbox, losses are primarily from gear meshing, bearing friction, and oil churning/splashing.

Spur Gear Mesh Efficiency ($\eta_g$): Modeled using the Coulomb-like formula:

$$ \eta_g = 1 – k f \left( \frac{1}{z_1} \pm \frac{1}{z_2} \right) $$

where $k$ is a coefficient related to addendum height (≈2.3), $f$ is the friction coefficient (0.06-0.10), $z_1$ and $z_2$ are the teeth numbers of the pinion and gear, and the plus sign is for external meshing.

Worm Gear Mesh Efficiency ($\eta_w$): Crucially dependent on the lead angle ($\gamma$). When the worm is the driver:

$$ \eta_w = \frac{\tan \gamma}{\tan \gamma + \arctan \left[ \left( \frac{0.3979 \pi d_1 n_1}{60000 \cos \gamma} – 0.03407 \right)^{-0.353} \right] } $$

where $d_1$ is the worm pitch diameter and $n_1$ is the worm speed.

Other Efficiencies: Bearing pair efficiency ($\eta_2$) and oil churning efficiency ($\eta_3$) are typically taken as 0.99 and 0.98, respectively. Chain drive efficiency ($\eta_{chain}$) is estimated at 0.98.

Thus, the total efficiencies for the two speeds are:

$$ \eta_{I}^{total} = \eta_w \cdot \left(1 – k f \left( \frac{1}{z_{3}} + \frac{1}{z_{5}} \right)\right) \cdot \left(1 – k f \left( \frac{1}{z_{7}} + \frac{1}{z_{9}} \right)\right) \cdot \eta_{chain} \cdot \eta_2^6 \cdot \eta_3^2 $$

$$ \eta_{II}^{total} = \eta_w \cdot \left(1 – k f \left( \frac{1}{z_{4}} + \frac{1}{z_{6}} \right)\right) \cdot \left(1 – k f \left( \frac{1}{z_{7}} + \frac{1}{z_{9}} \right)\right) \cdot \eta_{chain} \cdot \eta_2^6 \cdot \eta_3^2 $$

3.2 Modeling Gearbox Volume

The overall volume is approximated by the sum of the volumes of the gear blanks and the worm wheel rim. Minimizing this is key to material savings and compactness.

Spur Gear Volume ($V_g$):

$$ V_g = \sum_{i=3}^{9} \frac{\pi b_i d_{ai}^2}{4} $$

where $b_i$ is the face width and $d_{ai} = m_i (z_i + 2h_a^*)$ is the addendum diameter of gear $i$.

Worm Wheel Rim Volume ($V_w$): The rim volume is critical as it uses costlier bronze material.

$$ V_w = \frac{\pi \psi m^3 (q+2)}{4} \left[ \left( u z_1 + 2 + \frac{6}{z_1+2} \right)^2 – (u z_1 + 6.4)^2 \right] $$

where $\psi$ is the face width coefficient, $m$ is the module, $q$ is the diameter factor, $u$ is the gear ratio ($z_2/z_1$), and $z_1$ is the number of worm threads.

Total Volume ($V_{total}$):

$$ V_{total} = V_g + V_w $$

3.3 Formulating the Multi-Objective Optimization Problem

The optimization aims to find the best set of design parameters that simultaneously maximize efficiency and minimize volume. The design variable vector $\mathbf{X}$ includes 18 parameters related to the worm gears and spur gears:

$$\mathbf{X} = [\gamma, m_w, z_1, q, z_2, z_3, z_4, z_5, z_6, z_7, z_9, \phi_{d2}, \phi_{d3}, \phi_{d4}, \phi_{d7}, m_3, m_4, m_7]^T$$

The objective functions to be minimized (where maximizing efficiency is equivalent to minimizing its negative) are:

$$ \min F(\mathbf{X}) = \left( -\eta_{I}^{total}(\mathbf{X}), \, -\eta_{II}^{total}(\mathbf{X}), \, V_{total}(\mathbf{X}) \right) $$

Constraints include geometric, strength, and design rules:

- Bending and Contact Stress: $\sigma_{F_i} \leq [\sigma_F]$ and $\sigma_{H_i} \leq [\sigma_H]$ for all gears.

- Gear Geometry: Minimum teeth to avoid undercutting ($z_{min} \geq 17$), face width coefficients within practical bounds (0.4 to 0.9).

- Worm Gear Design: Lead angle bounds ($3^\circ \leq \gamma \leq 28^\circ$), worm thread count ($z_1 \in \{1, 2\}$), diameter factor bounds.

- Assembly: Center distance equality for the two spur gear paths: $m_3(z_3+z_5) = m_4(z_4+z_6)$.

- Discrete Variables: Gear modules ($m_3, m_4, m_7, m_w$) must be selected from standard series (e.g., 1.25, 1.5, 2, 2.5, 3, 4…).

4. Optimization via Genetic Algorithm

Given the mixed continuous-discrete nature of the variables and the multi-objective formulation, a Genetic Algorithm (GA) is employed using the MATLAB Global Optimization Toolbox (`gamultiobj`). The GA effectively searches the complex design space to find a Pareto-optimal front of solutions, representing the best trade-offs between efficiency and volume.

The algorithm handles discrete variables (like module) by defining them as integer indices pointing to an array of standard values. Nonlinear constraints, such as stress equations, are transformed into penalty functions or linearized bounds where applicable.

5. Optimization Results and Analysis

The GA successfully converged to an optimized set of parameters. The table below contrasts the key initial design guesses with the final optimized values.

| Parameter | Initial Design | Optimized Design |

|---|---|---|

| Worm Lead Angle ($\gamma$) | 3° 13′ 28″ | 9° 11′ 17″ |

| Worm Module ($m_w$) | 3 mm | 2 mm |

| Worm Threads ($z_1$) | 1 | 1 |

| Worm Wheel Teeth ($z_2$) | 46 | 61 |

| Spur Gear Teeth ($z_3$, $z_4$, $z_5$, $z_6$) | 40, 23, 100, 117 | 25, 29, 111, 73 |

| Spur Gear Teeth ($z_7$, $z_9$) | 32, 96 | 37, 111 |

| Face Width Coefficients ($\phi_{d2}, \phi_{d3}, \phi_{d4}, \phi_{d7}$) | 0.30, 0.30, 0.40, 0.45 | 0.45, 0.50, 0.50, 0.50 |

| Spur Gear Modules ($m_3, m_4, m_7$) | 2.0, 2.0, 2.5 mm | 1.5, 2.0, 2.0 mm |

| Speed I Total Efficiency ($\eta_{I}^{total}$) | 0.6058 (60.58%) | 0.7435 (74.35%) |

| Speed II Total Efficiency ($\eta_{II}^{total}$) | 0.6253 (62.53%) | 0.7564 (75.64%) |

| Estimated Gearbox Volume ($V_{total}$) | 0.0136 m³ | 0.0122 m³ |

Analysis of Results:

- Significant Efficiency Gains: The optimization yielded a remarkable increase in total transmission efficiency—approximately 13.77% for Speed I and 13.11% for Speed II. This leap is primarily attributed to:

- The optimized, larger lead angle ($\gamma$) of the worm gears, which directly increases its meshing efficiency.

- More balanced gear ratios and optimized face width coefficients, leading to better load distribution and reduced losses in the spur gear stages.

- Reduced Volume: Despite improvements, the overall gearbox volume was reduced by 10.30%. This was achieved by:

- Reducing the module of some spur gears and the worm gears, allowing for smaller gear diameters.

- Optimizing the tooth counts and ratios to achieve a more compact layout while maintaining strength requirements.

- Design Improvements: The optimized face width coefficients are more uniform and closer to 0.5, promoting better design practice for load carrying capacity and alignment. The use of a smaller module worm gears pair with a higher lead angle demonstrates an optimal trade-off between size reduction and efficiency enhancement.

6. Experimental Validation

A test bench was constructed to validate the performance of the new worm gears-based transmission system against the traditional turbine-driven system. The bench used a variable-speed DC motor, the optimized gearbox, and a winch-and-weight system to simulate the dragging force on the hose reel.

The input power was measured via a torque transducer on the motor shaft, and the output power was calculated from the weight force and the linear speed of the cable. The system efficiency ($\eta$) was calculated as:

$$ \eta = \frac{P_{out}}{P_{in}} = \frac{F \cdot v}{M \cdot n / 9550} $$

where $F$ is the weight force (N), $v$ is the cable speed (m/s), $M$ is motor torque (N·m), and $n$ is motor speed (rpm).

The following table summarizes sample experimental results comparing the two systems under various loads and input speeds.

| Simulated Load (kg) | Prime Mover Speed (rpm) | Traditional Turbine-Driven System | Optimized DC Motor + Worm Gear System | ||

|---|---|---|---|---|---|

| Gear Path I | Gear Path II | Gear Path I | Gear Path II | ||

| 1000 | ~700 / 1400* | 50.1 | 42.9 | 75.1 | 73.9 |

| 800 | ~700 / 1400* | 46.4 | 40.7 | 73.0 | 70.9 |

| 600 | ~700 / 1400* | 41.3 | 36.5 | 66.0 | 66.7 |

| 400 | ~700 / 1400* | 33.8 | 30.2 | 59.0 | 60.3 |

| 200 | ~700 / 1400* | 22.7 | 19.0 | 47.9 | 49.6 |

| *Note: Turbine and motor operate at different efficient speed ranges. Data aligned for comparable output conditions. | |||||

Key Experimental Findings:

- The optimized worm gears-based transmission system consistently and significantly outperforms the traditional system across all tested load conditions.

- The experimental efficiencies for the new system (ranging from ~48% to 75%) align reasonably well with the theoretical predictions from the optimization model (~74-76%), validating the model’s accuracy.

- The efficiency advantage of the new system is most pronounced at higher loads, which represent the more common and demanding operating conditions for the irrigator.

- The two-speed functionality performed reliably, providing distinct and efficient operating points for different required sprinkler travel speeds.

7. Conclusion

This study successfully demonstrates the redesign and optimization of a hose reel irrigator transmission system. The integration of a worm gears stage as the primary reduction element, combined with a strategically configured two-speed spur gear assembly, effectively addressed the limitations of traditional multi-stage spur gear designs.

The application of a multi-objective genetic algorithm, considering mixed continuous-discrete variables, proved highly effective in navigating the complex design space. The optimization yielded a Pareto-improved solution: simultaneously increasing the total transmission efficiency by over 13% and reducing the estimated gearbox volume by over 10%.

The experimental results confirmed the superior performance of the optimized worm gears-based system compared to the conventional turbine-driven approach. The new design offers a more compact, efficient, and reliable transmission solution, enabling better speed control, lower energy consumption, and enhanced performance for hose reel irrigation machines. This methodology provides a valuable framework for the development and upgrading of transmission systems in agricultural machinery where high reduction ratios and space efficiency are critical.