In the context of advancing marine oil and gas exploration, jack-up platforms are increasingly deployed in harsh and deep-water environments. As water depths grow, the legs of these platforms become longer, exacerbating structural and buoyancy challenges. A critical issue that demands immediate attention is enhancing the support between the platform hull and its legs, particularly by improving the locking capability of the legs. This study focuses on the design and research of an innovative locking mechanism based on screw gears, which offers a robust solution for load transfer and stability in such demanding conditions.

The jack-up platform is a complex structural system comprising several legs, a deck, and elevation devices, widely used in offshore oil operations. With the expansion of marine oil industries into deeper waters, the environmental conditions faced by these platforms have become more severe. Currently, over half of the constructed and under-construction offshore platforms in my region utilize fixed-pile locking systems. However, domestically produced locking systems are limited to a few platforms, such as HYSY 931 and HYSY 921/922/923/924. The market is largely monopolized by foreign manufacturers, leading to high costs and inconvenient after-sales services. Therefore, the localization of locking systems is imperative. Recent developments in domestic marine industries, coupled with national emphasis on energy security, have spurred increased investment and research efforts by various enterprises and institutions.

Current Development Status Globally and Domestically

In terms of the number of offshore drilling units, international giants like Transocean dominate the market, whereas domestic drilling contractors lag significantly. Despite vast marine resources, the配套数量 of offshore drilling equipment in my country is insufficient, necessitating expansion to meet operational demands. Historically, three widely used locking mechanism schemes have emerged:

- Hydraulic pin locking for truss-type legs.

- Pneumatic locking systems for leg securing.

- Rack-and-pinion elevation systems with tooth-shaped wedge locking.

Each scheme has its advantages and limitations, which I will analyze in detail.

Comparative Analysis of Locking Schemes

To evaluate the effectiveness of different locking mechanisms, I have summarized key parameters in Table 1. This comparison highlights the superiority of screw gear-based systems in deep-water applications.

| Scheme | Advantages | Disadvantages | Suitability for Deep-Water |

|---|---|---|---|

| Hydraulic Pin Locking | Simple structure, early adoption | Shear stress limits, intermittent locking, high hydraulic pressure requirements | Low |

| Pneumatic Locking | Quick operation, reduced complexity | Limited load capacity, sensitivity to environmental conditions | Moderate |

| Rack-and-Pinion with Wedge Locking | Continuous locking, high precision, reliable performance | Higher cost, complex manufacturing | High |

| Screw Gears Locking (Proposed) | Self-locking, compact design, efficient load transfer | Requires precise engineering | Very High |

The hydraulic pin locking scheme, while simple, suffers from drawbacks such as shear stress concentration on pins, similar to a cantilever beam model. This limits its application due to material strength constraints. Additionally, it integrates climbing and locking functions, leading to long operational cycles and low efficiency. The need for multiple hydraulic cylinders and high working pressures further complicates the system. Moreover, the intermittent locking height due to pin-hole配合 reduces environmental adaptability, and the cylindrical legs require high-precision machining, increasing costs and weight.

In contrast, screw gears locking mechanisms, which I propose, overcome these limitations by offering continuous adjustment and robust self-locking capabilities.

Determination of the Design Scheme

My design employs vertically arranged upper and lower screws, wedge-shaped pressure blocks, and a six-tooth locking block layout, driven by hydraulic power. This configuration facilitates load transfer, equalization, and unlocking operations with simplicity, lightness, reliability, and cost-effectiveness. The process involves several steps:

- Prior to locking, the platform is lowered to the operational air gap.

- The lower screw assembly adjusts the height of the locking teeth, while side-push cylinders engage the locking rack with the leg rack. The top hydraulic motor drives the screw downward, pushing the upper wedge to press against the locking rack. Similarly, the lower hydraulic motor drives the screw upward, engaging the lower wedge.

- This sequence is repeated for the other side and additional chord pipes to complete pre-locking operations.

- After unloading hydraulic cylinders and motors, the platform weight is transferred to the six upper screw assemblies, completing dynamic load transfer.

- Finally, the six lower screw assemblies are operated to support the locking rack, securing the leg entirely.

This scheme ensures quick and reliable unlocking, with the entire process optimized for minimal downtime. The use of screw gears is central to this design, providing the necessary torque and precision for effective locking.

Design of the Screw Gears Locking Mechanism

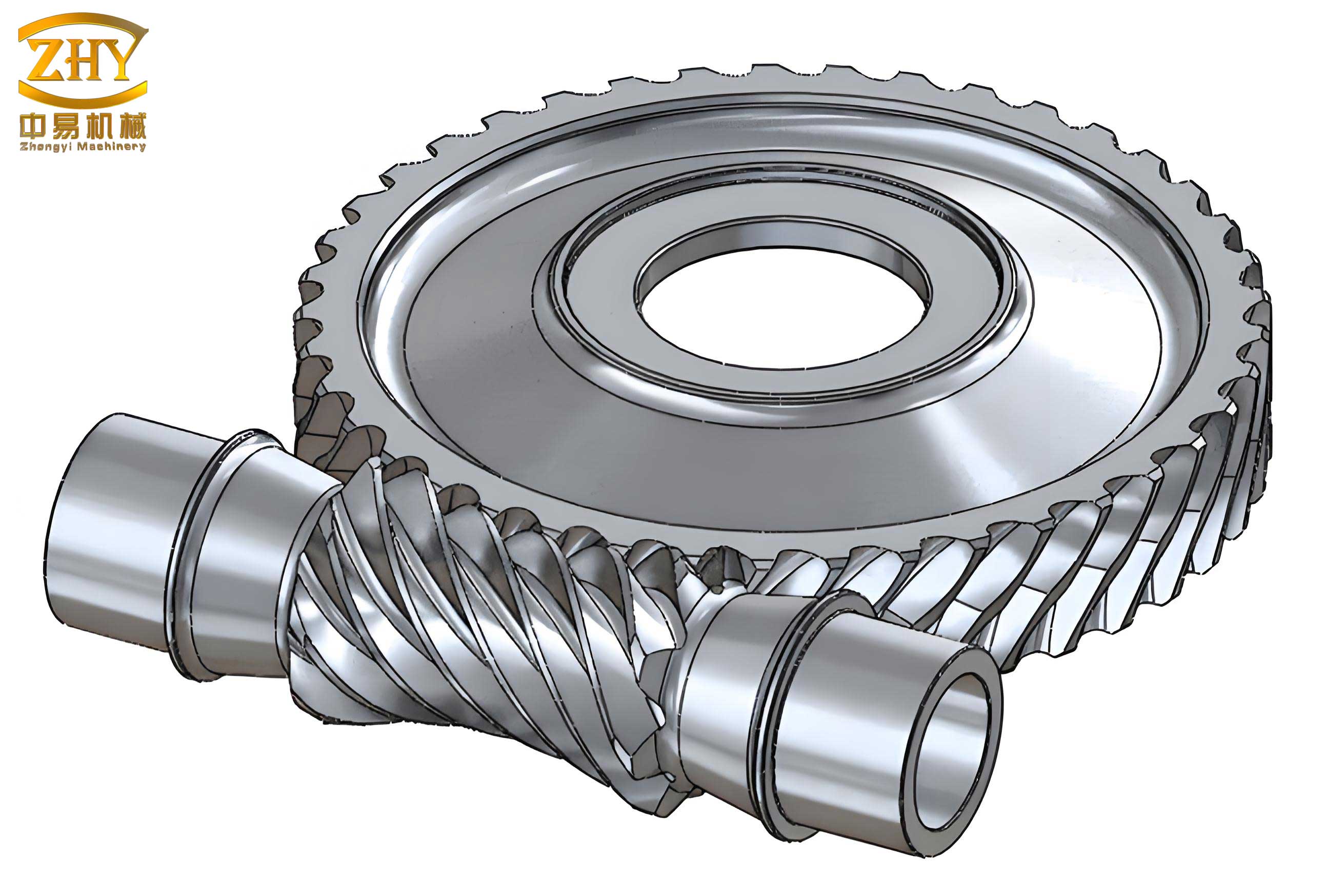

Screw gears, specifically worm gear drives, are spatial mechanisms that transmit motion and force between intersecting shafts. In power transmission, they offer high reduction ratios, up to 300, and even 1000 for motion transmission alone. This makes them compact and efficient. The continuous helical teeth of the worm engage gradually with the worm wheel, resulting in smooth operation, low noise, and reduced impact loads due to multiple contact points. A key feature for locking applications is self-locking, which occurs when the lead angle of the worm is less than the equivalent friction angle, typically below 35 degrees. This ensures that the mechanism remains securely locked without external power.

In my design, I have developed an异形 screw gear structure where the worm wheel incorporates an internal thread to mate with the screw, combining characteristics of power transmission screws. This hybrid approach allows for intermittent operation with self-locking capability. The screw gears mechanism involves the worm rotating to drive the screw, which then moves vertically to compress triangular wedges, achieving locking. This design is simple, easy to manufacture, and inherently self-locking.

The mechanical advantages of screw gears can be expressed through formulas. For instance, the transmission ratio of a worm gear set is given by:

$$i = \frac{z_2}{z_1}$$

where \(z_2\) is the number of teeth on the worm wheel and \(z_1\) is the number of starts on the worm. In my design, I optimize this ratio for high torque output. The self-locking condition is defined as:

$$\lambda < \phi$$

where \(\lambda\) is the lead angle and \(\phi\) is the friction angle. For reliable locking, I ensure \(\lambda\) is minimized, typically below 5 degrees in practical applications. The efficiency of the screw gears mechanism can be estimated using:

$$\eta = \frac{\tan \lambda}{\tan (\lambda + \phi)}$$

which highlights the trade-off between self-locking and efficiency. To enhance performance, I incorporate materials with low friction coefficients, such as bronze for the worm wheel and hardened steel for the worm.

Key design parameters for the screw gears locking mechanism are summarized in Table 2, based on computational analysis and simulation results.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Worm Diameter | \(d_w\) | 150 | mm |

| Worm Wheel Teeth | \(z_2\) | 40 | – |

| Worm Starts | \(z_1\) | 2 | – |

| Transmission Ratio | \(i\) | 20 | – |

| Lead Angle | \(\lambda\) | 4.5 | degrees |

| Friction Angle | \(\phi\) | 6 | degrees |

| Efficiency | \(\eta\) | 0.45 | – |

| Maximum Load Capacity | \(F_{max}\) | 5000 | kN |

The screw gears assembly consists of components such as the worm, worm wheel, bearings, and seals, arranged to withstand high axial loads. The internal thread of the worm wheel engages with the screw, allowing for precise linear motion. This configuration reduces overall weight while maintaining high torque transmission, making it ideal for offshore applications where space and weight are critical. In my research, I have validated this design through finite element analysis, confirming stress distributions and safety factors under extreme loads.

Furthermore, the integration of hydraulic motors with the screw gears enables rapid adjustment and locking. The hydraulic system provides the necessary power to rotate the worm, which in turn drives the screw. This combination ensures quick response times and reliable operation in dynamic sea conditions. The use of screw gears in this context not only enhances locking performance but also simplifies maintenance due to fewer moving parts compared to traditional systems.

Operational Advantages and Future Implications

The screw gears locking mechanism offers several benefits for jack-up platforms. It employs a rack-and-pinion elevation system with tooth-shaped wedges, utilizing vertically arranged screws, wedge blocks, and six-tooth locking racks. Hydraulic驱动 allows for efficient load transfer, equalization, and unlocking. The design is characterized by simplicity, completeness of function, operational reliability, low cost, and light weight. The legs of cylindrical design feature racks welded on both sides, engaging with motor-driven gears for elevation. The locking racks typically use six teeth to minimize单齿负荷, and wedge blocks provide constraints in both vertical and horizontal directions through self-locking properties.

The extension and retraction of the screws are achieved via hydraulic motors driving the worm rotation. The worm wheel, with its internal thread design, mates with the screw, offering advantages such as light weight, high torque, simple structure, reliable performance, and stable transmission efficiency. This makes screw gears a cornerstone of modern locking systems for offshore platforms.

In conclusion, my research demonstrates that screw gears locking mechanisms are highly effective for deep-water jack-up platforms. By leveraging self-locking features and efficient power transmission, they address the challenges posed by increasing water depths and harsh environments. Future work will focus on optimizing材料 selection and scaling the design for ultra-deep-water applications. The widespread adoption of screw gears in this field promises to enhance safety, reduce costs, and support the sustainable development of marine oil resources.

Throughout this study, I have emphasized the importance of screw gears in achieving reliable locking. Their ability to provide high reduction ratios, self-locking, and compact design makes them indispensable for offshore engineering. As technology advances, further innovations in screw gears will likely drive improvements in platform stability and operational efficiency. I recommend continued investment in research and development to refine these mechanisms and expand their applications in the marine industry.