In the hot precision forging of bevel gears, the selection of preform shape and size is very important. It not only affects the tooth forming, but also affects the internal quality of forgings and the service life of forging dies. The following factors need to be considered in the design of preforms:

(1). The blank is easy to locate in the mold cavity;

(2). Metal is easy to fill the tooth mold cavity;

(3). It is easy to produce small and uniform flash during forming;

(4). During the forming process, the metal flow path is short, and part of the metal of the gear tooth mainly flows along the tooth profile to the tooth top.

For precision forged bevel gears, preforms and blanks are not the same concept. The preforms of precision forged bevel gears are generally

Cylinder, the blank is hot-rolled bar. Due to the high requirements for oxide scale in precision forging, the preform is obtained after the oxide scale is removed from the blank, and the size of the preform is different from that of the blank. The determination of preform size should ensure that the metal is filled smoothly in the pre forging die chamber with low forming force, and the determination of blank size should meet the requirements of national steel ruler specification. Therefore, when designing the preform size, in addition to considering that the metal can fill the pre forging die chamber smoothly, it should also make the preform size plus the oxide skin residue removed meet the national steel size requirements. When the two cannot be taken into account at the same time, it is necessary to determine the preform size according to whether the metal can smoothly fill the pre forging die chamber, and then select the smaller size of the national specifications close to the calculated blank size as the blank size. After the oxide scale is removed from the blank and before the pre forging, a rough step is added to obtain the appropriate size of the preform.

This paper mainly studies the influence of preform size on metal flow law, so the national steel size requirements are not considered in the design of preform size. The sizes designed below are all preform sizes for pre forging.

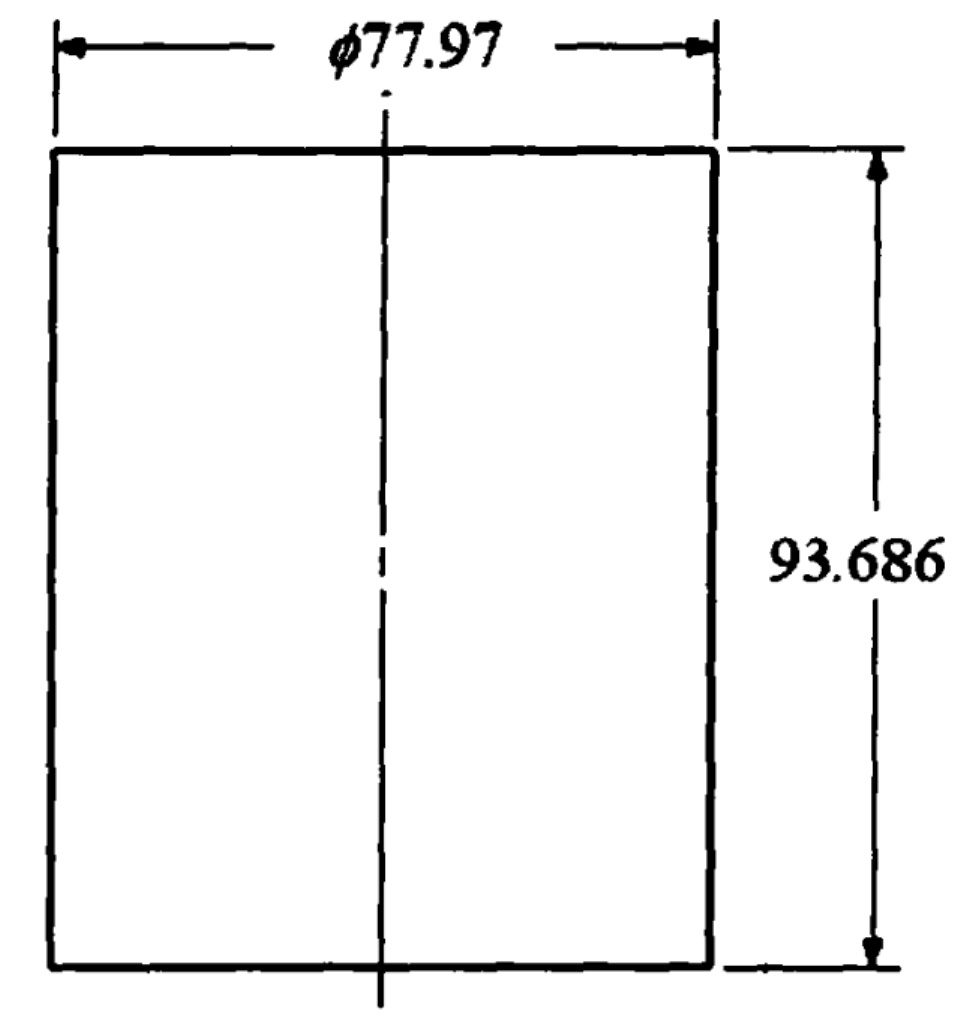

During the pre forging of the half shaft gear, the half shaft concave die is used for positioning, and a single side clearance of 0.6-1.0mm is generally reserved between the blank and the half shaft concave die. Dimension of preform for axle shaft gear is shown in the figure.

The diameter of planetary gear preform is generally selected from the diameter of tooth root circle and tooth tip circle of small end face. Large diameter makes the crown of the small end face of the forging mainly formed by back extrusion rather than rough forming The forming load is too large, and even there is “lack of meat”. However, too small diameter will lengthen the metal flow path, increase the metal deformation, and easily form internal defects.