It is proposed to use the warm and cold composite process to process spur gears. It is divided into pre forging and final forging. The plastic deformation of pre forging is large. Warm forging is adopted. The workpiece is less affected by oxidation, has good plasticity, less deformation resistance, and the microstructure and properties are also improved. The final forging deformation is small, and the cold forming method is adopted to ensure that the dimensional accuracy and surface quality of spur gear meet the design requirements. The process route is as follows:

Precision blanking – medium frequency induction heating – warm forging preform – punching skin – annealing – surface treatment – cold finishing – subsequent finishing – heat treatment.

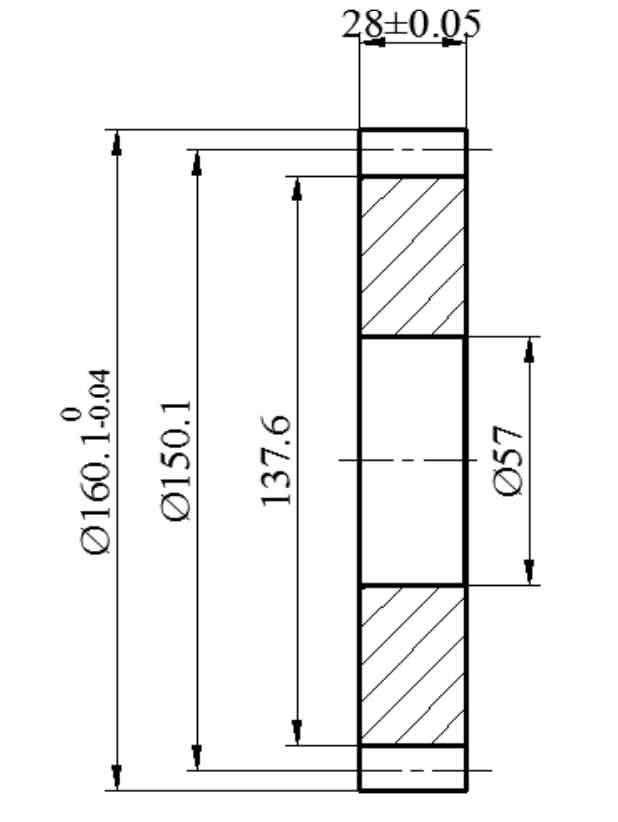

The forging drawing of final forging is the drawing of cold forging. According to the structure of 18crnimo7-6 spur gear, the spur gear hole needs to be forged during precision forging, and the diameter of the small boss is large. Considering that the contact area is too small during die forging, it is not easy to realize, and the boss is completed by subsequent machining. As for some details on the part drawing, such as fillet, chamfer and so on, it is simplified. However, in order to ensure the accuracy of the parts, it is necessary to reserve appropriate machining allowance on the forging drawing, reserve 1.5mm unilateral allowance for the inner hole and 1mm unilateral allowance for both ends. Due to the high accuracy requirements of the spur gear, 0.1mm bilateral allowance is reserved for the tooth profile. The forging drawing is shown in the figure below.