The spiral bevel gear blank should be heated to 1150 ℃ for die forging, which belongs to hot die forging. Therefore, the die cavity should be designed based on the hot forging drawing.

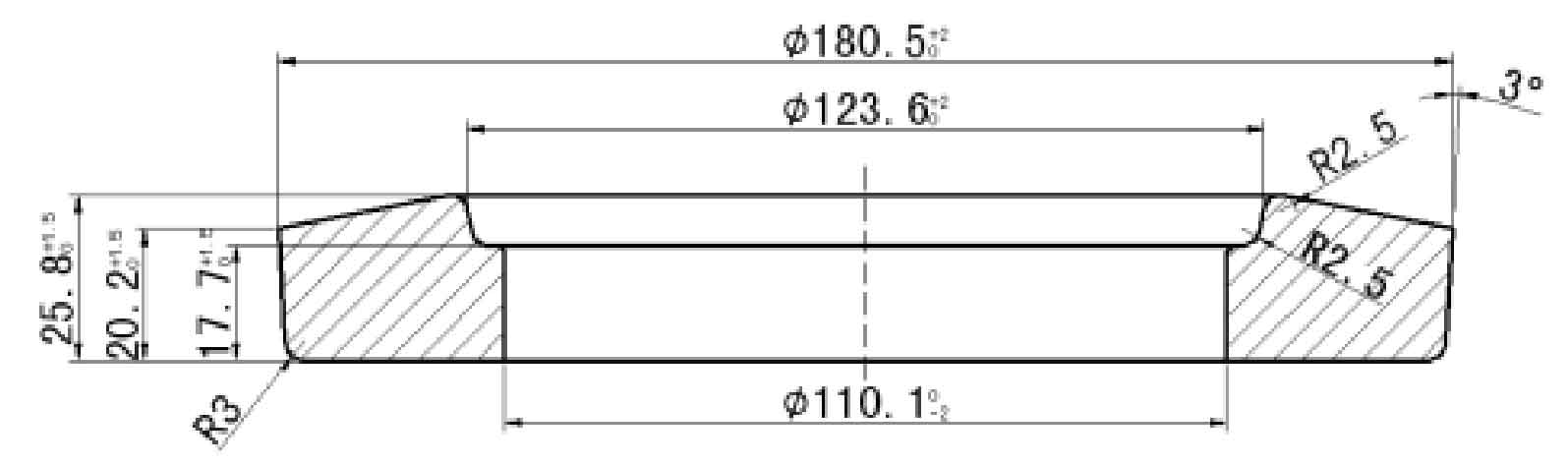

Generally, the shrinkage rate of alloy steel forgings is 1% ~ 1.5%. The size determination of hot forging drawing is to draw the hot forging drawing after taking the shrinkage rate into account on the basis of forging drawing, as shown in Figure 1.

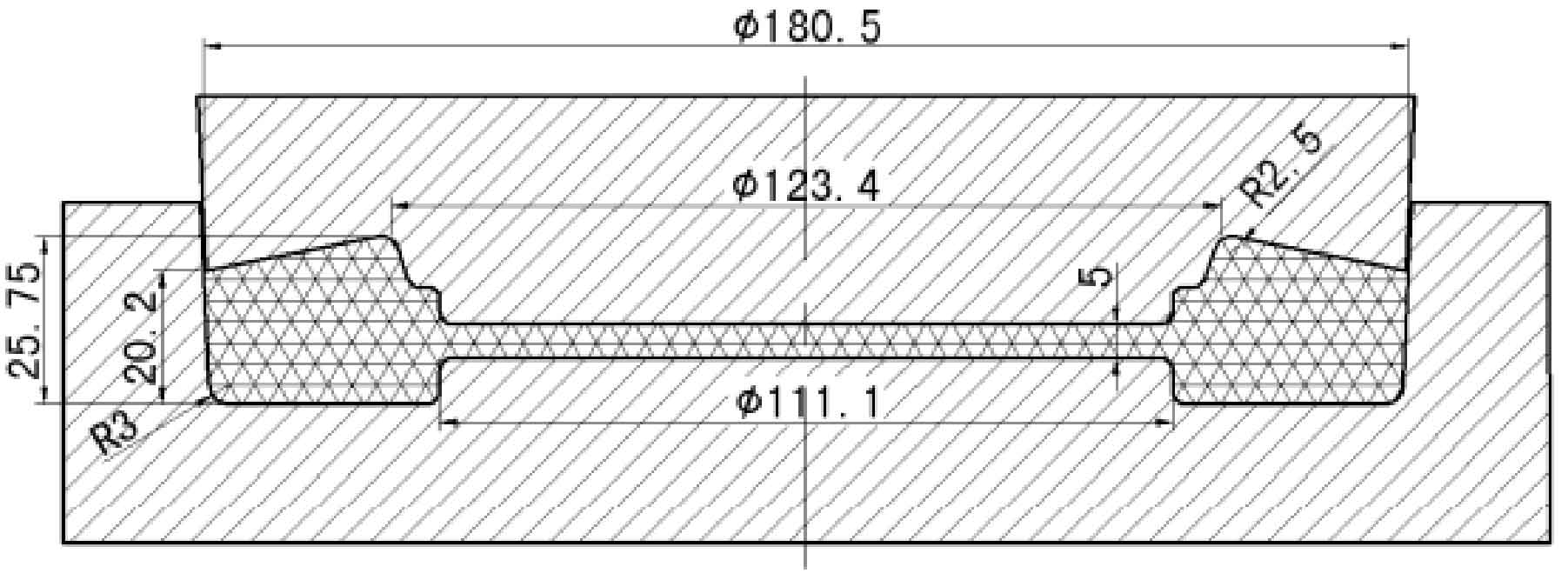

According to figure 1, the die bore of closed die forging of spiral bevel gear blank is designed, as shown in Figure 2.