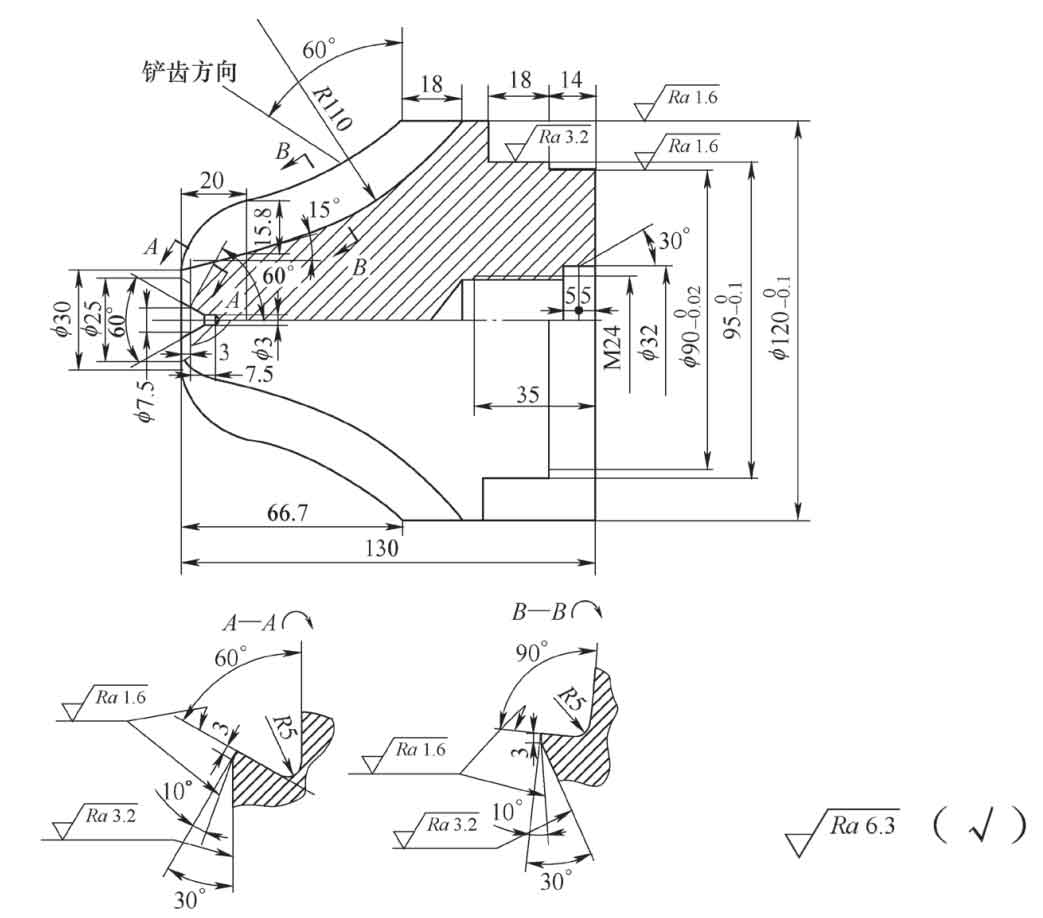

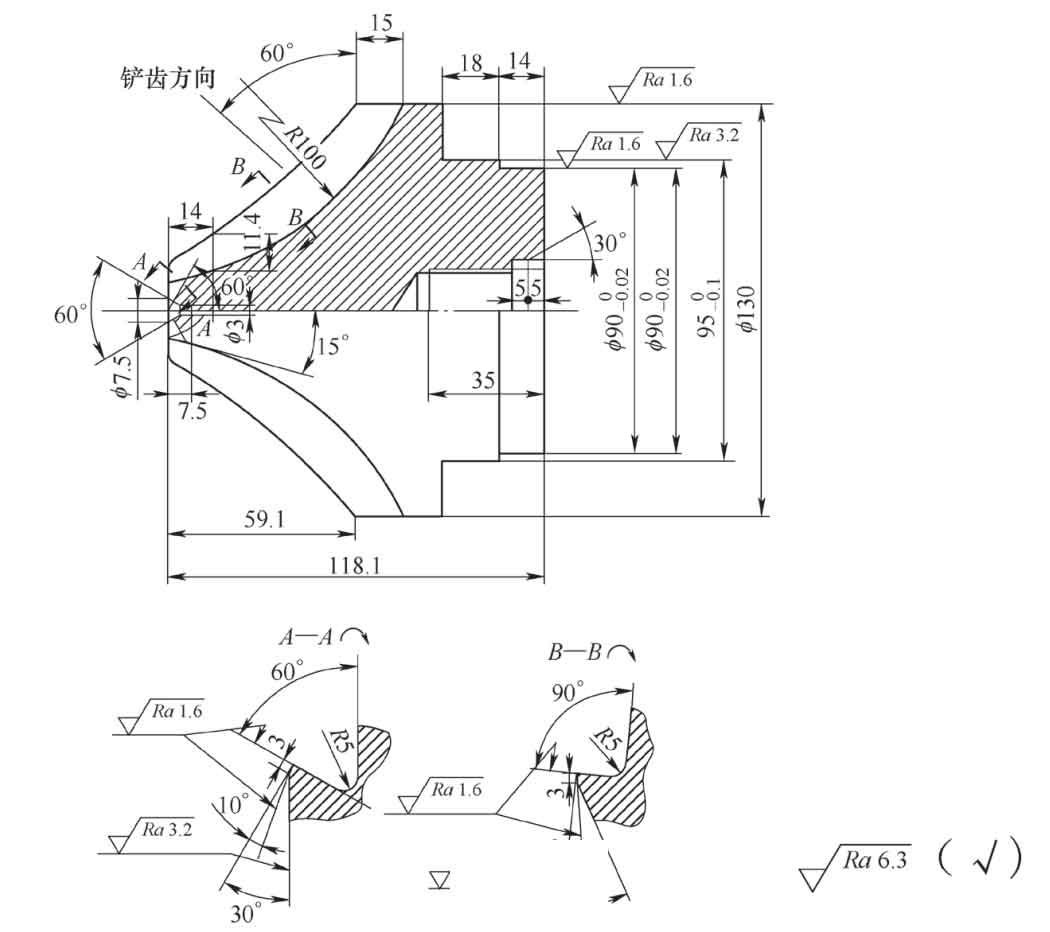

According to the connection mode between the tool and the shank used by our company, the tool structure is designed with reference to the non-standard tool design manual and the tool design manual. The cutting edge of the milling cutter shall be designed in full accordance with the tooth profile template designed above, and the other parts shall be designed in accordance with the tool design standard and the connection mode with the shank. According to the above two tooth profile templates, two finger milling cutters with different shapes are designed. The first milling cutter (6 teeth) is shown in Figure 1 and the second milling cutter (4 teeth) is shown in Figure 2.

The finger milling cutter designed according to the above method has a maximum diameter of 130mm, a tool length of 117mm and a mass of about 10kg. It effectively solves the problem of the connection rigidity between the tool and the tool handle and the spindle.

Due to the low machining accuracy requirements of the gear shaft, the meshing clearance between the gear shaft and the rack is large, and the maximum tooth side clearance is 1.5mm. The tooth profile processed by the above method can fully meet the use requirements. Through this method, the technical problem of processing the tooth profile of large module gear shaft of 900t mixer furnace in our company is solved, which not only ensures the production period, but also reduces the processing cost.

This special processing method of gear shaft tooth profile provides a new idea for other enterprises to process large module gears under the condition of insufficient equipment.