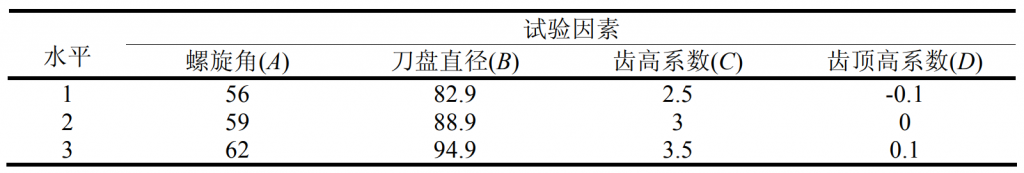

The purpose of orthogonal trial calculation is to find the key geometric factors and the best combination of hypoid gears. This method can replace the optimization design method to a certain extent. The tooth cutting limit condition and strength balance condition of hypoid gear are integrated into the pitch cone angle of hypoid gear. That is, the increase of pitch cone angle of hypoid gear small wheel is equivalent to the decrease of surface cone angle of hypoid gear large wheel. At the same time, the equivalent number of teeth of hypoid gear small wheel is increased, and the strength of hypoid gear small wheel is also increased. Four factors affecting the pitch cone angle are selected, and each factor has three levels. The selected factor levels are shown in Table 1. According to professional knowledge, several factors affecting the pitch cone angle of hypoid gear are roughly determined, including midpoint helix angle, cutter head diameter, tooth height coefficient and tooth top height coefficient.

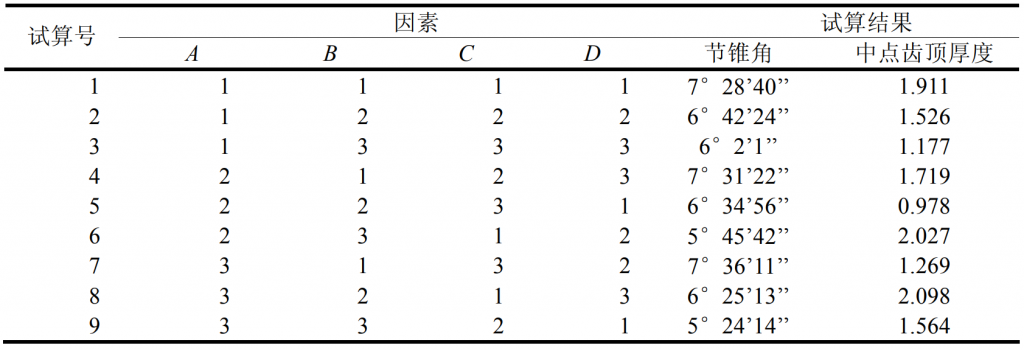

Because this trial calculation considers the trial calculation of four factors and three levels, without considering the interaction between various levels, the four factors account for four columns, and the four factors are placed arbitrarily. The trial calculation scheme is shown in Table 2. A total of 9 calculations are required, and 9 groups of pitch cone angles and midpoint addendum thickness are calculated by using the developed geometric parameter design program.